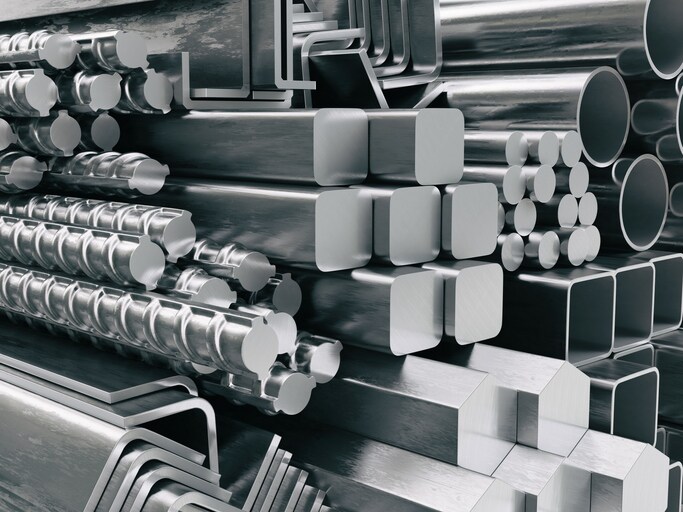

Austenitic Stainless Steel

Austenitic stainless steel, characterized by its high chromium and nickel content, offers exceptional corrosion resistance, ductility, and weldability. These properties make it an ideal material for tank manufacturing, where durability and longevity are paramount. Its non-magnetic nature and ability to maintain strength at high temperatures further enhance its suitability for various industrial applications, ensuring reliable performance under harsh conditions.

Characteristics of austenitic stainless steel

Corrosion Resistance:

- High chromium content provides excellent resistance to a wide range of corrosive environments.

- Effectively withstands exposure to acids, bases, and saline solutions.

Weldability:

- Exceptional weldability with minimal risk of cracking during welding processes.

- Ideal for complex fabrications requiring strong, durable welds.

Formability:

- Can be easily formed, bent, or drawn into complex shapes without losing strength.

- Versatile for applications requiring intricate designs.

Non-Magnetic:

- Inherently non-magnetic, making it suitable for applications where magnetic interference is a concern.

High-Temperature Performance:

- Maintains strength and integrity at high temperatures.

- Suitable for use in environments where materials are exposed to extreme heat.

Ductility:

- High ductility allows it to be stretched or deformed without breaking.

- Enables the production of thin-walled components and complex shapes.

These characteristics collectively make austenitic stainless steel an ideal choice for a broad spectrum of applications, including tank manufacturing, food processing equipment, and architectural structures, ensuring durability, safety, and aesthetic appeal.

Characteristics of austenitic stainless steel

| Grade | C (Max) | Mn (Max) | P (Max) | S (Max) | Si (Max) | Cr | Ni | Mo | N (Max) | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM 304 / EN 1.4301 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-10.5 | - | - | - |

| ASTM 304L / EN 1.4306 | 0.03 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-12.0 | - | - | - |

| ASTM 316 / EN 1.4401 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - | - |

| ASTM 316L / EN 1.4432 | 0.03 | 2.0 | 0.045 | 0.030 | 1.0 | 16.5-18.5 | 10.0-13.0 | 2.5-3.0 | - | - |

| ASTM 317L / EN 1.4438 | 0.03 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | - | - |

| ASTM 321 / EN 1.4541 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - | Ti ≥ 5xC, max 0.70% |

| UNS S31050 / EN 1.4466 | 0.02 | 2.0 | 0.035 | 0.015 | 0.8 | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.10-0.22 | Cu: 0.5-1.5, N: 0.10-0.22 |

| UNS N08020 / Carpenter 20 CB3 | 0.07 | 2.0 | 0.045 | 0.035 | 1.0 | 19.0-21.0 | 32.0-38.0 | 2.0-3.0 | - | Cu: 3.0-4.0, Nb: 0.1-0.3 |

Physical properties of austenitic stainless steel

| Grade | Density (g/cm³) | Melting Point (°C) | Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/mK) | Specific Heat (J/kgK) | Electrical Resistivity (nΩm) |

|---|---|---|---|---|---|---|

| ASTM 304 / EN 1.4301 | 8.0 | 1400-1450 | 16.2 | 16.2 | 500 | 720 |

| ASTM 304L / EN 1.4306 | 8.0 | 1400-1450 | 16.3 | 16.3 | 500 | 720 |

| ASTM 316 / EN 1.4401 | 8.0 | 1375-1400 | 16.5 | 16.3 | 500 | 740 |

| ASTM 316L / EN 1.4432 | 8.0 | 1375-1400 | 16.5 | 16.3 | 500 | 740 |

| ASTM 317L / EN 1.4438 | 8.0 | 1375-1400 | 16.5 | 16.5 | 500 | 740 |

| ASTM 321 / EN 1.4541 | 8.0 | 1400-1450 | 16.6 | 16.1 | 500 | 720 |

| UNS S31050 / EN 1.4466 | 8.0 | 1375-1400 | 16.0 | 14.0 | 500 | 750 |

| UNS N08020 / Carpenter 20 CB3 | 8.1 | 1350-1400 | 17.0 | 12.9 | 500 | 800 |

Applications of austenitic stainless steel

Austenitic stainless steels are widely utilized in various industries due to their exceptional corrosion resistance, durability, and formability. Below are detailed descriptions of their applications across different sectors, with a focus on tank and heavy-duty container manufacturing:

Chemical Processing Industry

Austenitic stainless steels, such as ASTM 316 and 316L (EN 1.4401 and EN 1.4432), are extensively used in the chemical processing industry due to their superior corrosion resistance to a wide range of chemicals. These materials are ideal for tanks and vessels that store and process acidic and basic solutions, as well as organic compounds. Their molybdenum content enhances their resistance to chloride environments, making them suitable for use in high-concentration chloride solutions and reducing the risk of stress corrosion cracking.

Food and Beverage Industry

The food and beverage industry favors austenitic stainless steels like ASTM 304 and 304L (EN 1.4301 and EN 1.4306) for their excellent corrosion resistance, ease of cleaning, and non-toxicity. These grades are commonly used in the manufacturing of storage tanks, fermenters, and processing equipment where hygiene and product purity are paramount. Their resistance to a wide range of food and beverages, from acidic fruits to alkaline solutions, prevents contamination and maintains the quality of the products.

Pharmaceutical Industry

In the pharmaceutical industry, where cleanliness and contamination control are critical, austenitic stainless steels such as ASTM 316L (EN 1.4432) offer the necessary corrosion resistance and ease of sterilization. Equipment and containers, including reactors, storage tanks, and piping systems, benefit from the material's smooth surface, reducing the adherence of bacteria and residues. Its excellent weldability also ensures that joints and seams do not become sites for bacterial growth.

Water Treatment and Desalination

The resistance of austenitic stainless steels to chloride-induced corrosion makes them ideal for water treatment and desalination plants. Grades like UNS S31653 (EN 1.4429) and ASTM 317L (EN 1.4438) are used in the construction of tanks, pipes, and heat exchangers that are exposed to brackish or seawater. These materials withstand the aggressive environments encountered in desalination processes, ensuring the longevity and reliability of the equipment.

Oil and Gas Industry

The oil and gas industry utilizes austenitic stainless steels for storage tanks, separators, and pipelines that handle crude oil, natural gas, and by-products. High-performance grades, such as UNS N08020 (Carpenter 20 CB3) and UNS S31050 (EN 1.4466), provide excellent resistance to sulfide stress cracking and corrosive substances found in petroleum products. Their high strength and toughness at low temperatures also make them suitable for offshore platforms

AISI 321 / S32100 stainless steel

AISI 321 / S32100 stainless steel

ASTM 304 - EN 1.4301

ASTM 304 - EN 1.4301

ASTM 304L - EN 1.4306

ASTM 304L - EN 1.4306

ASTM 304L ( EN 1.4307 ) Stainless Steel

ASTM 304L ( EN 1.4307 ) Stainless Steel

ASTM 304LN - EN 1.4311

ASTM 304LN - EN 1.4311

ASTM 347 - EN 1.4550

ASTM 347 - EN 1.4550

UNS S30430 - EN 1.4567

UNS S30430 - EN 1.4567

ASTM 316 - EN 1.4401

ASTM 316 - EN 1.4401

EN 1.4436 / ASTM 316 Stainless Steel

EN 1.4436 / ASTM 316 Stainless Steel

ASTM 316L - EN 1.4432

ASTM 316L - EN 1.4432

ASTM 316LN - EN 1.4406

ASTM 316LN - EN 1.4406

UNS S31653 - EN 1.4429

UNS S31653 - EN 1.4429

ASTM 316L - EN 1.4435

ASTM 316L - EN 1.4435

ASTM 317LMN - EN 1.4439

ASTM 317LMN - EN 1.4439

UNS S31050 - EN 1.4466

UNS S31050 - EN 1.4466

UNS N08020 | Carpenter 20 CB3 Stainless Steel

UNS N08020 | Carpenter 20 CB3 Stainless Steel

ASTM 321 - EN 1.4541

ASTM 321 - EN 1.4541

ASTM 316L - EN 1.4404

ASTM 316L - EN 1.4404

ASTM 317L - EN 1.4438

ASTM 317L - EN 1.4438