AISI 321 stainless steel Features

1.Superior Corrosion Resistance: AISI 321 matches types 302 or 304 in corrosion resistance when annealed. Its titanium addition significantly enhances protection against intergranular corrosion, making it robust in aggressive chemical environments and superior in conditions where annealing after welding isn't feasible.

2.High-Temperature Performance: Uniquely suited for service in temperatures ranging from 800 °F to 1600 °F, it maintains strength and oxidation resistance, outperforming many stainless steels in thermal stability.

3.Weldability and Structural Integrity: This grade offers exceptional weldability, eliminating the need for post-weld annealing. This feature ensures the maintenance of mechanical properties and structural integrity in welded constructions, making it preferable for critical applications.

4.Versatile Formability: AISI 321's excellent formability allows it to be shaped and formed into complex structures without compromising its mechanical properties, offering design flexibility across various applications.

SS321 chemical composition

| Element |

Content (%) |

Role in Alloy |

| Carbon |

0.08 max |

Strength, weldability |

| Manganese |

2.00 max |

Deoxidizes, hardens |

| Silicon |

0.75 max |

Strength, elasticity |

| Chromium |

17.00 - 19.00 |

Corrosion resistance |

| Nickel |

9.00 - 12.00 |

Toughness, corrosion resistance |

| Molybdenum |

0.75 max |

Refines grain, corrosion resistance |

| Phosphorus |

0.045 max |

Strength, corrosion resistance |

| Sulfur |

0.030 max |

Improves machinability |

| Copper |

0.75 max |

Corrosion resistance, strength |

| Nitrogen |

0.010 max |

Strength, hardness |

| Titanium |

5x (C+N) min - 0.70 max |

Stabilizes, prevents carbide precipitation |

| Iron |

Balance |

Matrix of the alloy |

AISI 321 stainless steel Physical Properties

| Density |

0.29 lbs/in3 9.01 g/cm3 |

| Electrical Resistivity |

microhm-in (microhm-cm): 68 °F (20 °C): 28.4 (72) |

| Specific Heat: BTU/lb/°F (kJ/kg•K): |

32 - 212 °F (0 - 100 °C): 0.12 (0.50) |

| Thermal Conductivity |

BTU/hr/ft2/ft/°F (W/m•K):

At 212 °F (100 °C): 9.3 (16.0)

At 932 °F (500 °C): 12.8 (22.0) |

| Mean Coefficient of Thermal Expansion |

in/in/°F (µm/m•K)

32 - 212 °F (0 - 100 °C): 9.2 x 10·6 (16.6)

32 - 600 °F (0- 315 °C): 9.5 x 10·6 (17.1)

32 - 1000 °F (0 - 538 °C): 10.3 x 10·6 (18.5)

32 - 1200 °F (0 - 649 °C): 10.7 x 10·6 (19.3)

32 - 1500 °F (0 - 873 °C): 11.2 x 10·6 (20.2) |

| Modulus of Elasticity |

ksi (MPa)

28 x 103 (193 x 103) in tension

11 .2 x 103 (78 x 103) in torsion |

| Magnetic Permeability |

H = 200 Oersteds: Annealed < 1.02 max |

| Melting Range |

2500 - 2550 °F (1371 - 1400 °C) |

| Ultimate Tensile Strength |

75 KSI min (515 MPa min) |

| Yield Strength (0.2% Offset) |

30 KSI min (250 MPa min) |

| Elongation |

40% min |

| Hardness |

Rb 95 max |

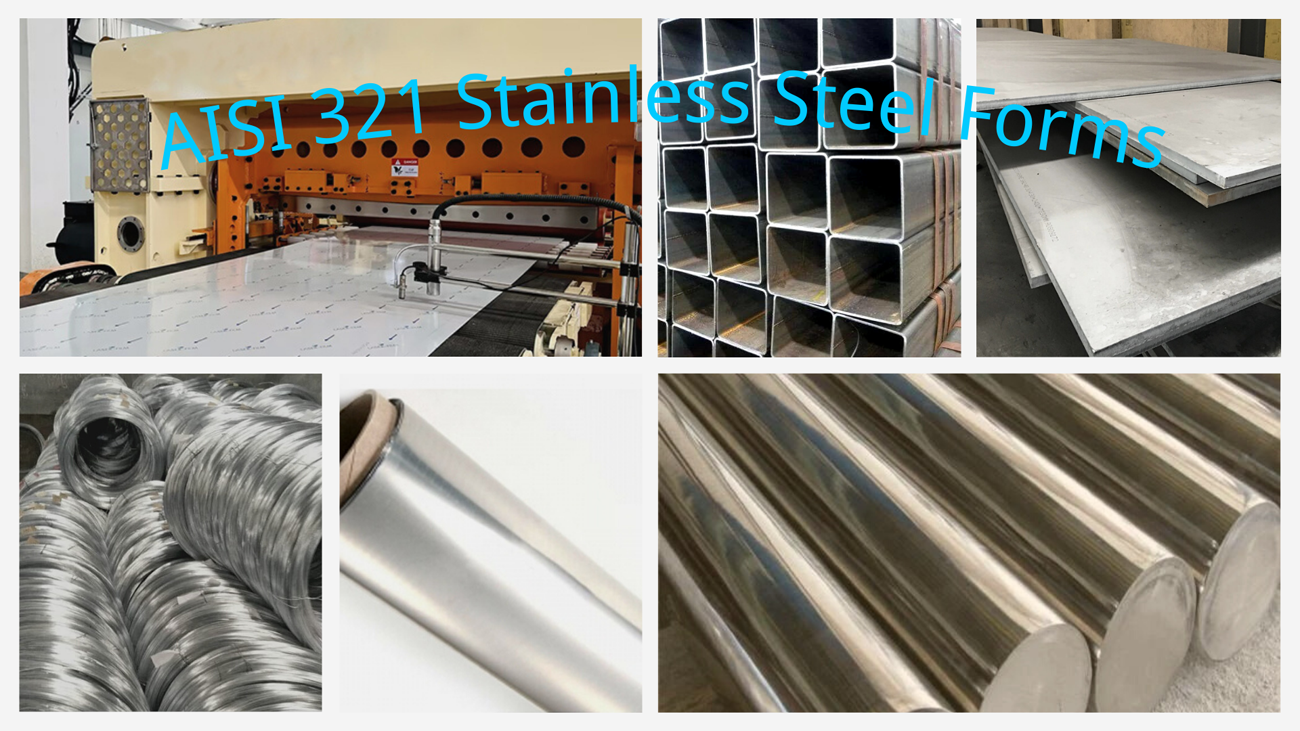

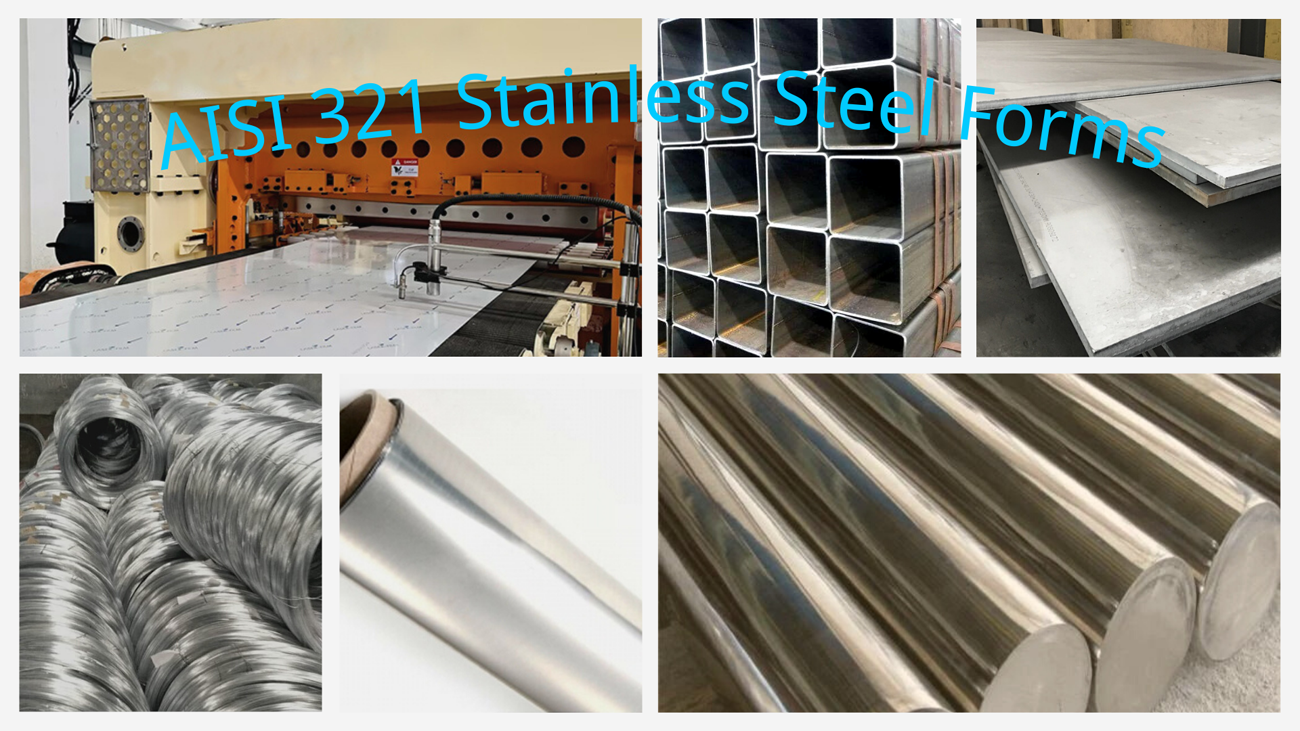

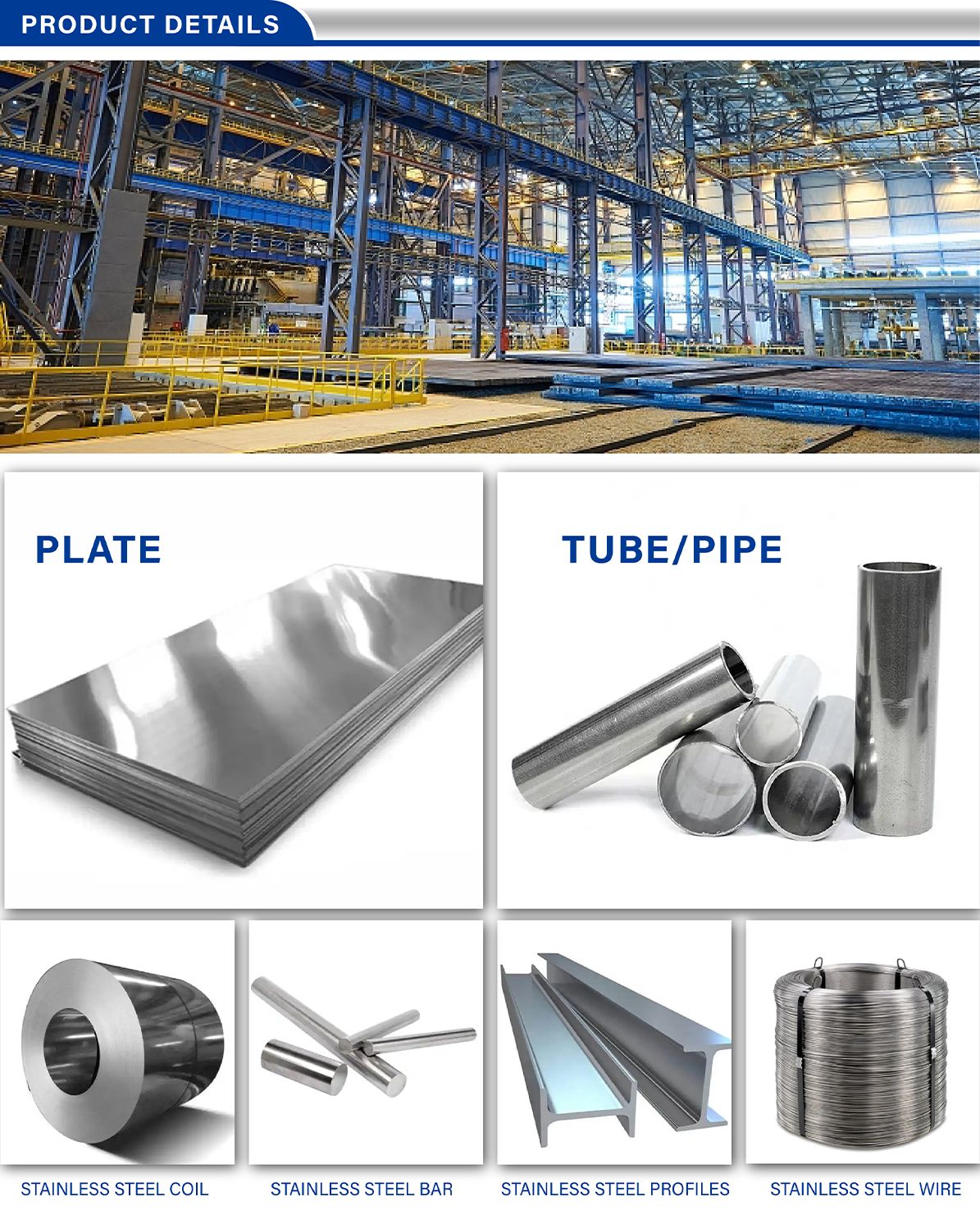

AISI 321 stainless steel Forms

Heat Treatment:

Heat treating AISI 321 stainless steel involves several steps to optimize its properties:

1.Annealing: Heat to 1800-2000°F (982-1093°C) and hold for a sufficient time to allow for full recrystallization. This process softens the steel, enhances its corrosion resistance, and prepares it for further processing.

2.Quenching: Rapid cooling in water or air. This step is crucial for locking in the annealed structure and preventing the formation of phases that could diminish corrosion resistance and mechanical properties.

3.Stabilizing: If required, a stabilizing heat treatment at 1550-1650°F (843-899°C) can be performed to ensure maximum resistance to intergranular corrosion, especially beneficial if the steel has been heavily worked or welded.

AISI 321 stainless steel Applications:

1.Aircraft Collector Rings & Exhaust Stacks: Offers exceptional resistance to oxidation at high temperatures, crucial for aircraft parts exposed to extreme heat.

2.Carburetor Air Intensifier Tubes & Exhaust Manifolds: The alloy's stability in thermal environments ensures reliable performance in automotive systems, reducing maintenance.

3.Flexible Couplings & Jet Engine Parts: Its excellent fatigue strength supports the durability and integrity of engine components and coupling systems under dynamic stress.

4.Mufflers, Pressure Vessels & Tubing: AISI 321's sound dampening qualities and pressure resistance make it ideal for mufflers and vessels, ensuring safety and efficiency.

5.Fasteners, Flexible Metal Hose, and Bellows:: The material's corrosion resistance extends the lifespan of fasteners and flexible components, making it a cost-effective choice for industrial applications.

(FAQ) About AISI 321 stainless steel

1.Is 321 stainless better than 304?

Comparing AISI 321 to 304 stainless steel depends on the application requirements. AISI 321's addition of titanium offers enhanced high-temperature resistance and prevents intergranular corrosion, making it superior for applications involving thermal cycling or welding. AISI 304, however, might be preferred for general applications due to its excellent formability and corrosion resistance, coupled with a lower cost.

2.Which is better 321 or 316 SS?

The choice between AISI 321 and 316 stainless steel hinges on the specific environmental conditions and application. AISI 316 contains molybdenum, providing increased resistance to chloride corrosion, making it more suitable for marine environments. AISI 321 is better suited for high-temperature applications due to its titanium stabilization, which provides resistance to intergranular corrosion. Therefore, the "better" grade is context-dependent, focusing on the unique requirements of the application.

ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 ASTM 321 - EN 1.4541

ASTM 321 - EN 1.4541 UNS S32101- EN 1.4162

UNS S32101- EN 1.4162