Carpenter 20 CB-3 Stainless Steel, known as UNS N08020 or Alloy 20, is characterized by its unique blend of properties that make it ideal for various industrial applications, especially those involving corrosive environments.

UNS N08020 Main Features

1.Corrosion Resistance: Exhibits exceptional corrosion resistance to a wide range of chemicals, including sulfuric, phosphoric, and nitric acids. Its performance in sulfuric acid environments is particularly noteworthy.

2.Chemical Composition: Alloy 20 has a distinctive composition that includes nickel, chromium, molybdenum, and copper, which contribute to its excellent corrosion resistance and overall performance.

3.High Nickel Content: The high nickel content (32.00 - 38.00%) provides excellent resistance to stress-corrosion cracking in chloride-containing environments.

4.Chromium and Molybdenum Addition: Chromium (19.00 - 21.00%) offers oxidation resistance, while molybdenum (2.00 - 3.00%) enhances resistance to reducing environments.

5.Copper Addition: The presence of copper (3.00 - 4.00%) improves resistance to sulfuric acid.

6.Fabrication Flexibility: Can be fabricated using most standard industrial processes, including welding, without the need for pre-heating or post-weld heat treatment, making it versatile for manufacturing.

UNS N08020 Chemical Composition

- Nickel (Ni): 32.00 - 38.00%

- Chromium (Cr): 19.00 - 21.00%

- Copper (Cu): 3.00 - 4.00%

- Molybdenum (Mo): 2.00 - 3.00%

- Iron (Fe): Balance

- Manganese (Mn): Max 2.00%

- Carbon (C): Max 0.02%

- Silicon (Si): Max 0.07%

- Sulfur (S): Max 0.035%

- Phosphorous (P): Max 0.045%

Carpenter 20 CB3 Properties

| Physical Property |

• Density: 9.01 kg/m³

• Elongation: 30% min

• Tensile Strength: 627 MPa

• Yield Strength: 310 MPa

• Specific Heat Capacity: 0.500 J/g-°C |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

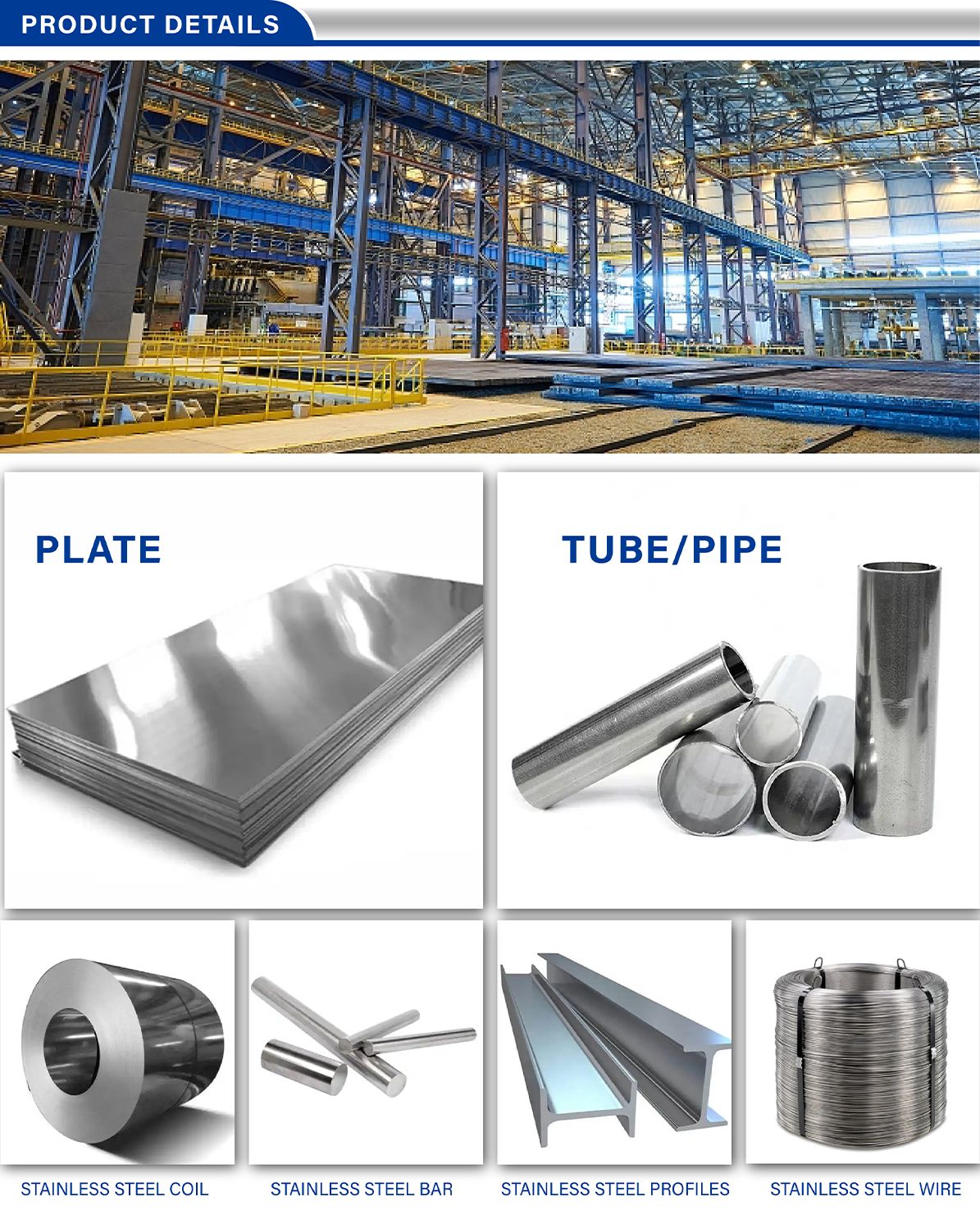

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

UNS N08020 - Carpenter 20 CB-3 is a superalloy used in various industries, such as chemical, food, pharmaceutical, and plastic industries. This alloy offers an excellent balance of corrosion resistance and heightened mechanical properties. Additionally, Carpenter 20 CB-3 is known for its ease of fabrication.

Typical Applications:

- Synthetic rubber manufacturing equipment

- Processing of pharmaceuticals, plastics and organic and heavy chemicals

- Tanks, piping, heat exchangers, pumps, valves, and other process equipment

- Acid cleaning and pickling equipment

- Chemical process piping, reactor vessels

- Bubble caps

- Petrochemical process equipment

- Food and dye production

Comparison with Other Materials

When choosing materials for industrial applications, understanding how UNS N08020, also known as Carpenter 20 CB3 Stainless Steel, compares with other stainless steels and alloys is crucial for making informed decisions. This section provides a comparative analysis focusing on key attributes and the unique advantages of UNS N08020.

Comparison with Other Stainless Steels and Alloys

1. Corrosion Resistance:

UNS N08020: This alloy is renowned for its exceptional resistance to sulfuric acid and other aggressive environments, outperforming standard stainless steels like 304 and 316 in terms of corrosion resistance. It also exhibits excellent resistance to stress-corrosion cracking.

304 and 316 Stainless Steels: While these are the most commonly used stainless steels, offering good corrosion resistance, they cannot match UNS N08020 in environments containing sulfuric acid or chlorides.

Duplex Stainless Steel (UNS S31803): Duplex stainless steels offer good resistance to a wide range of environments, including those that are corrosive. However, UNS N08020 still holds the upper hand in highly corrosive environments, particularly against reducing acids.

2. Mechanical Properties:

UNS N08020: Offers a combination of high strength and good ductility. Its mechanical properties are enhanced by the addition of copper and molybdenum, making it suitable for high-pressure applications.

316 Stainless Steel: While 316 provides good mechanical properties, UNS N08020 exceeds 316 in terms of strength, making it more suitable for demanding applications.

Alloy 625 (Inconel): Although Alloy 625 shows excellent strength and toughness, it is significantly more expensive than UNS N08020, making the latter a cost-effective alternative for many applications.

In conclusion, while there are many stainless steels and alloys available for various applications, UNS N08020 stands out in scenarios demanding high corrosion resistance, particularly against reducing acids, and where cost-effectiveness is a key consideration. Its unique combination of properties ensures it remains a preferred choice for challenging environments where longevity and performance are critical.

Additional FAQs on UNS N08020 and Related Terminologies

Can UNS N08020 be used in high-temperature applications?

Yes, UNS N08020 is suitable for use in high-temperature environments up to 1000°F (538°C). Its high nickel and chromium content provide excellent resistance to oxidation and maintain its structural integrity under high temperatures. However, for applications beyond this temperature range, it's important to consider other materials or consult with a materials expert to ensure performance and safety.

What material is UNS N08020?

UNS N08020, commonly known as Alloy 20 or Carpenter 20, is a nickel-chromium-molybdenum stainless steel alloy with additional copper and niobium. This combination results in a material with outstanding resistance to sulfuric acid, chlorine, and other aggressive chemicals. It is designed to withstand corrosive environments found in the chemical, petrochemical, and food processing industries.

What is 20CB-3® material?

20CB-3® is a brand name for UNS N08020, registered by Carpenter Technology Corporation. It refers to the same nickel-chromium-molybdenum stainless steel alloy known for its exceptional resistance to chemical corrosion, specifically to sulfuric acid. The "CB-3" suffix denotes the addition of columbium (niobium), which stabilizes the alloy and enhances its corrosion resistance.

What is Carpenter 20 stainless steel?

Carpenter 20 stainless steel, also known as UNS N08020 or Alloy 20, is a high-grade, nickel-containing stainless steel developed by Carpenter Technology Corporation. This alloy is engineered to offer superior resistance to acid corrosion, pitting, and crevice corrosion in chemical, solvents, and food processing environments. Carpenter 20 contains significant amounts of nickel, chromium, molybdenum, and copper, enhancing its corrosion resistance and making it an ideal choice for aggressive environments.

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel Super Duplex UNS S32750 / EN 1.4410

Super Duplex UNS S32750 / EN 1.4410 UNS S32304 - EN 1.4362

UNS S32304 - EN 1.4362 UNS S31200 - EN 1.4460

UNS S31200 - EN 1.4460 UNS S30430 - EN 1.4567

UNS S30430 - EN 1.4567 UNS S31050 - EN 1.4466

UNS S31050 - EN 1.4466 UNS S32760 - EN 1.4501

UNS S32760 - EN 1.4501 UNS S30900 - EN 1.4828

UNS S30900 - EN 1.4828