The Gr.9 (TC2) alloy is a nearly α-type titanium alloy, which is often referred to as "semi-TC4". It has a higher temperature application range than Gr.1-4. making it suitable for processes such as argon arc welding, spot welding and seam welding.

| Chemical Composition |

0.03N-0.08C-0.015H-0.25Fe-0.15O-2.5~3.5AI-2~3V |

| Physical Property |

• Tensile Strength: 620Mpa

• Yield Strength: 483 MPa

• Elongation: 15% |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

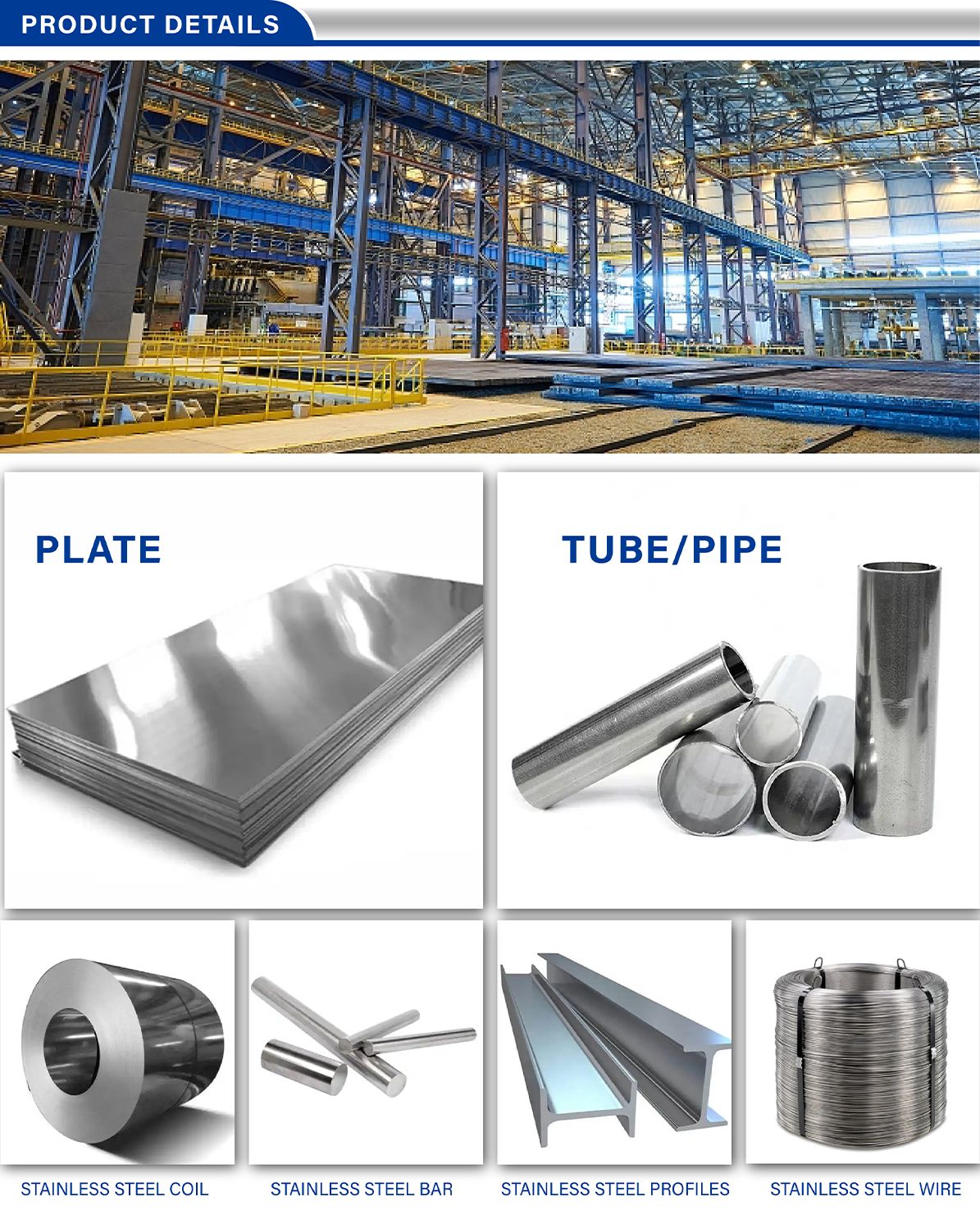

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

The Gr.9(TC2) alloy is a nearly α-type titanium alloy, usually called "semi-TC4". The application temperature is higher than that of Gr1-4. and it is suitable for argon arc welding, spot welding and seam welding. A near-α-type titanium alloy with medium strength and good plasticity, which contains 4% α-stable element Al and 1.5% β-stable element Mn. This alloy cannot be strengthened by heat treatment and is only used in the annealed state.

1.) Annealing: plates and plate parts: 660-710°C, 15-60min, air cooling or slower cooling; bars, forgings and pipes: 740-790°C, 1-2h, air cooling.

2.) Stress relief annealing, 545-585°C, 0.5-6h, air cooling or furnace cooling.

Gr.9(TC2) alloy has relatively satisfactory process plasticity, weldability and thermal stability. The long-term working temperature can reach 350°C, and the short-term working temperature is 750°C.

The plasticity of the process is good in the hot state, and complex parts can be made by hot stamping.

Application:

- Aviation industry

- Stamping

- Aircraft parts (accessories, engines, aircraft wings, etc.)

- Weldment

- Manufacturing

- Plate structural parts

- Catheter

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel AISI 444 Stainless Steel | EN 1.4521 Stainless Steel

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel A Guide to 304 Stainless Steel Tube Sizes

A Guide to 304 Stainless Steel Tube Sizes ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 Ti Gr.7 / 3.7235

Ti Gr.7 / 3.7235 Super Duplex UNS S32750 / EN 1.4410

Super Duplex UNS S32750 / EN 1.4410 Martensitic Stainless Steel X39CrMo17-1 / 1.4122

Martensitic Stainless Steel X39CrMo17-1 / 1.4122 10mm vs. 20mm Stainless Steel Plate: Which One Suits Your Project Best?

10mm vs. 20mm Stainless Steel Plate: Which One Suits Your Project Best?