Product Identification

Name: ALLOY 24

UNS Number: S34565

EN Number: 1.4565

Common Trade Names: Currently, ALLOY 24 is primarily recognized by its UNS and EN standard designations, S34565 and 1.4565, respectively. It may be referred to by different names by various manufacturers or in different markets, but these names are not standardized across the industry. For consistency and accuracy in identification, it is recommended to use the UNS or EN number when specifying or ordering this material. This approach ensures clarity and precision, avoiding any potential confusion with similar alloy grades or proprietary names that might be used by specific companies.

ALLOY 24 vs. ALLOY 904L Chemical Composition

The chemical composition of ALLOY 24 (UNS S34565 / EN 1.4565) is crucial for its superior properties, including enhanced corrosion resistance and mechanical strength. Below is a detailed breakdown of its composition. For comparison, a similar high-performance super-austenitic stainless steel, ALLOY 904L (UNS N08904 / EN 1.4539), is included to highlight differences in chemical makeup that influence their respective performance characteristics.

| Element | ALLOY 24 (UNS S34565 / EN 1.4565) (%) | ALLOY 904L (UNS N08904 / EN 1.4539) (%) |

| C | Max 0.03 | Max 0.02 |

| Mn | 3.5-6.5 | Max 2.00 |

| Si | Max 1.00 | Max 1.00 |

| P | Max 0.030 | Max 0.045 |

| S | Max 0.015 | Max 0.035 |

| Cr | 19.0 - 21.0 | 19.0 - 23.0 |

| Ni | 16.0 - 18.0 | 23.0 - 28.0 |

| Mo | 4.0 - 5.0 | 4.0 - 5.0 |

| N | 0.30 - 0.60 | Max 0.15 |

| Cu | 0.5 - 1.5 | 1.0 - 2.0 |

| Others | V: 0.10 - 0.30 | - |

Key Differences and Impact on Properties:

- Carbon (C) Content: Both alloys maintain a low carbon content to enhance corrosion resistance.

- Chromium (Cr) and Nickel (Ni): Similar ranges in Cr and Ni content contribute to their corrosion resistance, with ALLOY 24 having a slightly more focused range for optimized performance.

- Nitrogen (N): The higher N content in ALLOY 24 increases mechanical strength and corrosion resistance.

- Copper (Cu): Both alloys contain Cu to improve corrosion resistance in certain environments, with ALLOY 904L potentially having a slightly higher maximum.

- Vanadium (V): Present only in ALLOY 24, V contributes to improved hardness and strength through grain refinement.

These differences in chemical composition between ALLOY 24 and ALLOY 904L underscore the importance of selecting the right material based on the specific environmental conditions and performance requirements of the intended application. ALLOY 24's composition is engineered for environments where higher resistance to corrosion and strength are critical.

ALLOY 24 Properties

| Physical Property |

• Density: 8.04 kg/dm³

• Tensile Strength: 825 MPa

• Yield Strength: 440 MPa

• Longitudinal Elastic Modulus: 200 GPa

• Heat Conductivity: 500 W/(m·K)

• Specific Heat Capacity: 0.47 J/(kg·K) |

| Stock & Dimensions |

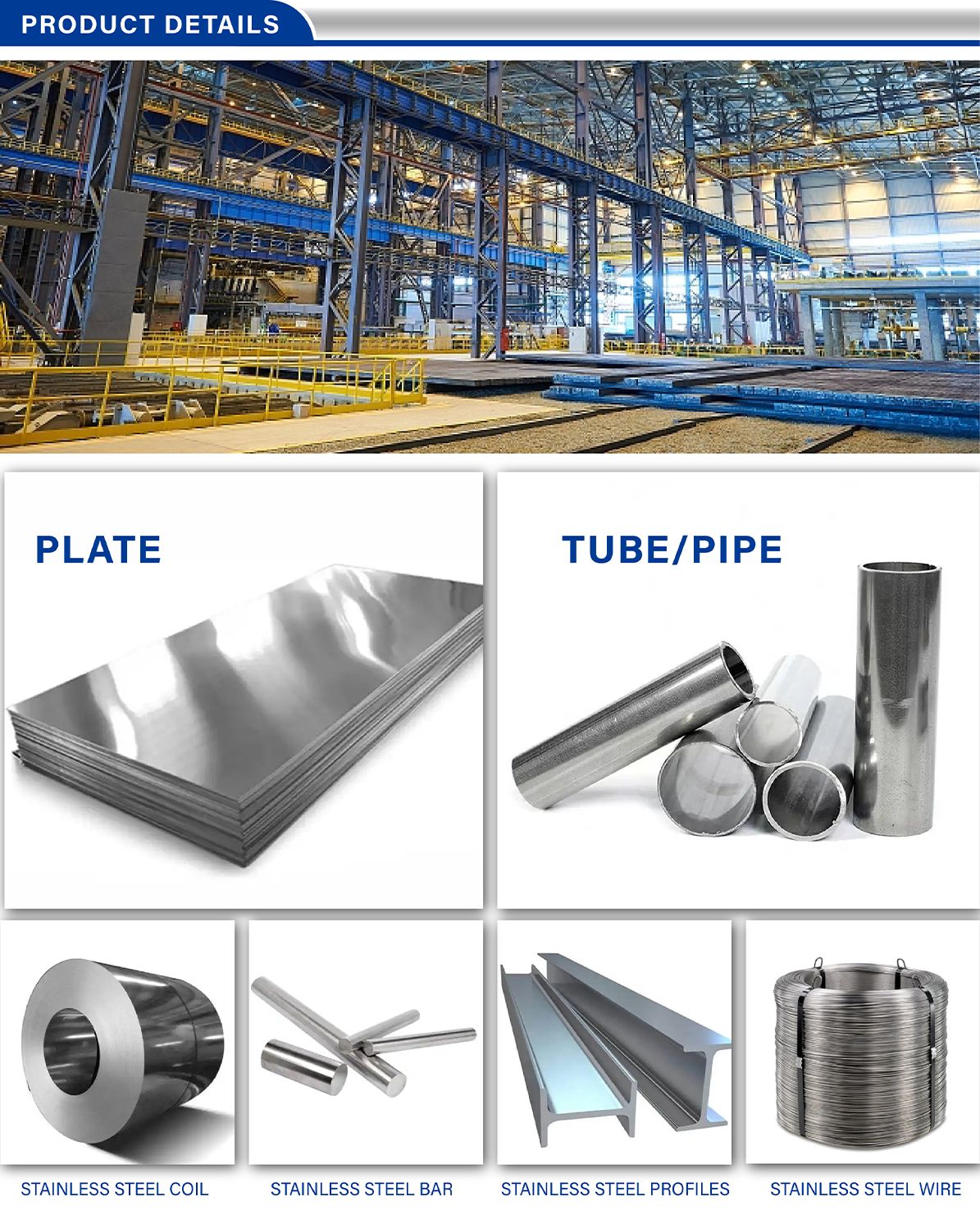

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Corrosion Resistance

ALLOY 24 (UNS S34565 / EN 1.4565) Stainless Steel is a super-austenitic stainless steel with high molybdenum and nitrogen content which provides notable corrosion resistance. Below is a detailed description of its corrosion resistance properties:

General Corrosion Resistance:

ALLOY 24 offers excellent general corrosion resistance superior to many conventional stainless steels. The high chromium and molybdenum content contribute to its ability to resist oxidation and maintain its integrity in a range of chemical environments.

Resistance to Specific Environments:

- Chlorides: ALLOY 24 has a high resistance to chloride-induced corrosion, including both pitting and crevice corrosion, which is a common problem in marine and harsh industrial environments.

- Acidic Environments: The alloy performs well in acidic environments, particularly against sulfuric, hydrochloric, and acetic acids, due to its high molybdenum content.

- Alkaline Environments: It also shows good resistance to alkaline solutions, although high pH levels coupled with high temperatures can challenge any stainless steel alloy.

Pitting and Crevice Corrosion Resistance:

Due to its enhanced chromium, molybdenum, and nitrogen content, ALLOY 24 has a high pitting resistance equivalent number (PREN) which makes it highly resistant to pitting and crevice corrosion, particularly in chloride-containing environments.

Stress Corrosion Cracking (SCC) Resistance:

ALLOY 24 is known for its excellent resistance to stress corrosion cracking. The combination of high nickel content with molybdenum and nitrogen provides a stable austenitic structure that performs well under stress in chloride-containing environments, reducing the risk of SCC.

It should be noted that while ALLOY 24 has excellent corrosion resistance, its performance may vary based on factors such as temperature, concentration of corrosive media, and presence of other elements in the environment. Regular testing and material verification are recommended for critical applications. Always consult with a corrosion expert or the material supplier for specific environmental assessments.

Typical Applications:

ALLOY 24 (UNS S34565 / EN 1.4565) Stainless Steel, given its exceptional corrosion resistance and strength, finds applications across various demanding industries. Here’s an overview of its typical uses:

Chemical Industry:

- Equipment for organic and inorganic chemicals: Used in reactors, piping, and storage tanks due to its resistance to a wide range of chemicals.

- Pharmaceutical production: The alloy's resistance to corrosion even in harsh sanitizing environments makes it suitable for pharmaceutical plant equipment.

Petrochemical Industry:

- Oil and gas production equipment: Ideal for use in the harsh conditions of offshore platforms and processing equipment due to its resistance to chloride and sulfur compounds.

- Refining: Components like heat exchangers, pipes, and valves that are exposed to corrosive fluids and gases.

Marine Industry:

- Ship and boat fittings: Due to its resistance to sea water and marine environments, it is used in ship hulls, water pumps, and piping systems.

- Desalination plants: Components that require resistance to high chloride environments.

Environmental and Water Treatment:

- Waste treatment equipment: ALLOY 24’s resistance to a variety of chemical exposures is valuable in waste treatment and chemical recycling plants.

- Desulfurization units: Its ability to withstand the corrosive environment in flue-gas desulfurization systems is critical.

Power Generation:

- Condensers and piping in nuclear and conventional power plants: Due to its ability to handle high-temperature and corrosive environments.

UNS N08020 | Carpenter 20 CB3 Stainless Steel

UNS N08020 | Carpenter 20 CB3 Stainless Steel Super Duplex UNS S32750 / EN 1.4410

Super Duplex UNS S32750 / EN 1.4410 UNS S32304 - EN 1.4362

UNS S32304 - EN 1.4362 UNS S31200 - EN 1.4460

UNS S31200 - EN 1.4460 UNS S30430 - EN 1.4567

UNS S30430 - EN 1.4567 UNS S31050 - EN 1.4466

UNS S31050 - EN 1.4466 UNS S32760 - EN 1.4501

UNS S32760 - EN 1.4501 UNS S30900 - EN 1.4828

UNS S30900 - EN 1.4828