Martensitic Stainless Steel X39CrMo17-1, with the material number 1.4122, represents a high-grade alloy that is engineered for superior performance in challenging environments. This steel is characterized by a martensitic crystal structure, achieved through a specific heat treatment process, enabling a unique combination of mechanical properties.

x39crmo17-1 chemical composition

The chemical composition of X39CrMo17-1 / 1.4122 is carefully balanced to provide optimal properties:

| Element |

Percentage (%) |

Function |

| Carbon (C) |

0.33-0.45 |

Provides hardness and strength through heat treatment. |

| Chromium (Cr) |

15.5-17.5 |

Enhances corrosion resistance and toughness. |

| Molybdenum (Mo) |

0.80-1.30 |

Improves wear resistance and strength at high temperatures. |

| Manganese (Mn) |

Max 1.0 |

Contributes to the steel's strength and hardness. |

| Silicon (Si) |

Max 1.0 |

Acts as a deoxidizer and improves strength. |

| Phosphorus (P) |

Max 0.035 |

Improves machinability and hardness. |

| Sulfur (S) |

Max 0.030 |

Increases machinability but is kept low to ensure good weldability and toughness. |

| Nickel (Ni) |

A nominal content |

Can enhance toughness but is kept relatively low compared to other stainless steels. |

x39crmo17-1 Stainless Steel Properties

| Physical Property |

• Density: 7.7 g/cm³

• Thermal Expansion: 10.4 x10^-6/K

• Modulus of Elasticity: 215 GPa

• Thermal Conductivity: 15 W/m.K

• Electrical Resistivity: 0.8 x10^-6 Ω .m |

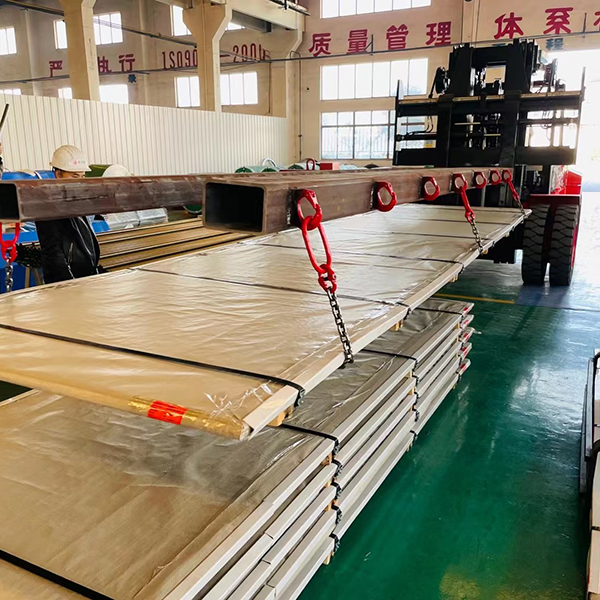

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

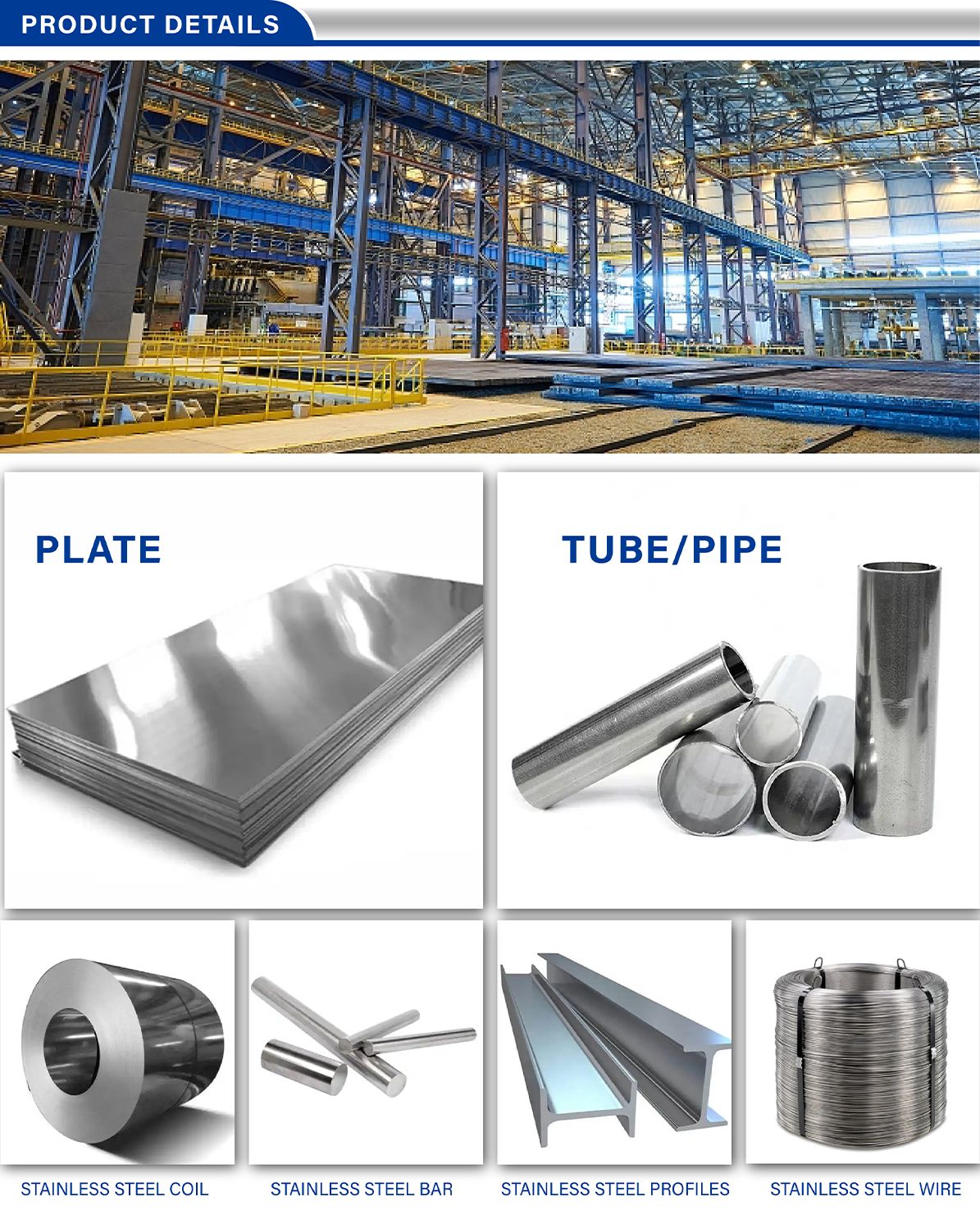

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Distinction from Other Stainless Steels

Martensitic stainless steels like X39CrMo17-1 / 1.4122 are distinguishable from austenitic and ferritic stainless steels primarily by their heat-treatable nature, which allows for the achievement of high hardness and strength. Unlike austenitic steels, which are non-magnetic and have higher chromium and nickel content for enhanced corrosion resistance but lower hardness, martensitic steels can be hardened and are magnetic. Compared to ferritic stainless steels, which cannot be hardened by heat treatment and have moderate corrosion resistance, martensitic steels offer a superior combination of strength, hardness, and corrosion resistance, making them ideal for more demanding applications.

Features and Benefits of X39CrMo17-1 / 1.4122

Martensitic Stainless Steel X39CrMo17-1 / 1.4122 is distinguished by a set of remarkable features and benefits, making it a material of choice for various demanding applications. Here’s a detailed examination of its key attributes:

High Hardness and Strength After Heat Treatment

X39CrMo17-1 / 1.4122 undergoes a transformation through heat treatment, achieving high levels of hardness and mechanical strength. This process involves heating the steel to a critical temperature followed by quenching and tempering. The result is a robust material capable of withstanding significant stress and load, making it ideal for applications requiring durability and longevity.

Excellent Wear and Corrosion Resistance

The alloy's unique composition, especially the high chromium content, grants it excellent resistance to wear and corrosion. Chromium forms a passive layer of chromium oxide on the surface, protecting the steel from various corrosive media. Additionally, the inclusion of molybdenum further enhances its corrosion resistance, particularly in environments susceptible to pitting and crevice corrosion. This makes X39CrMo17-1 / 1.4122 suitable for use in harsh chemical environments, as well as in situations where mechanical parts are subjected to friction and wear.

Magnetic Properties

Unlike austenitic stainless steels, X39CrMo17-1 / 1.4122 exhibits magnetic properties due to its martensitic crystal structure. This characteristic can be advantageous in applications where magnetic responsiveness is required, such as in actuating devices, sensors, and certain electrical and electronic components.

In summary, Martensitic Stainless Steel X39CrMo17-1 / 1.4122 stands out for its excellent combination of mechanical properties and corrosion resistance. Its versatility makes it suitable for a wide array of applications, ranging from simple tools to complex engineering components requiring precision and durability.

X39CrMo17-1 / 1.4122 Applications:

- Surgical instruments

- Food processing equipment

- Mechanical components

- Machine and pump systems

FAQs on X39CrMo17-1 / 1.4122

1.What Are the Best Practices for Heat Treating X39CrMo17-1 / 1.4122?

For optimal results, X39CrMo17-1 / 1.4122 should be heat treated with precision. Start by preheating the steel to avoid thermal shock and ensure an even temperature throughout. The hardening process involves heating to between 1020°C and 1050°C, followed by rapid cooling (quenching) in oil or air to achieve high hardness. Tempering is then applied, usually at temperatures between 150°C and 200°C, to achieve the desired balance of hardness and toughness. It's crucial to follow specific tempering guidelines based on the intended application of the steel to optimize performance.

2.How to Prevent Corrosion and Maintain X39CrMo17-1 / 1.4122?

Despite its excellent corrosion resistance, maintaining X39CrMo17-1 / 1.4122 is essential for longevity. Regular cleaning to remove contaminants that may cause surface pitting is recommended. Use mild detergents and avoid chlorine-containing cleaners. In highly corrosive environments, protective coatings or cathodic protection may be employed. Regular inspections can help identify and address any corrosion early, preventing widespread material degradation.

3.What Applications Are Most Suitable for X39CrMo17-1 / 1.4122?

X39CrMo17-1 / 1.4122 is highly versatile, suitable for applications requiring a balance of strength, wear resistance, and corrosion resistance. This includes cutlery, medical instruments, mechanical parts like gears and shafts, and components in aggressive environments such as valve and pump parts in chemical processing. Its high performance under stress and in corrosive environments makes it a reliable choice for critical applications across various industries.

4.How Does X39CrMo17-1 / 1.4122 Compare to Other Martensitic Stainless Steels?

X39CrMo17-1 / 1.4122 stands out among martensitic stainless steels for its superior wear and corrosion resistance, attributed to its specific chemical composition. While it offers similar hardness and strength to other martensitic steels, its chromium and molybdenum content provides enhanced protection against corrosive substances. This makes it more suitable than many other martensitic steels for applications in harsh environments, offering an excellent balance between mechanical properties and corrosion resistance.

Customer Reviews for XFT X39CrMo17-1 / 1.4122

-

1.Alexander Dubois

★★★★★

"Its exceptional hardness and corrosion resistance have significantly reduced our maintenance downtime. "

-

2.Maria Gonzalez

★★★★★

"Since switching to X39CrMo17-1 / 1.4122, we've seen a remarkable improvement in the lifespan of our products. Truly impressed with its performance!"

-

3.Sophia Patel

★★★★★

"Offering excellent wear resistance and ease of sterilization"

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel AISI 444 Stainless Steel | EN 1.4521 Stainless Steel

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel UNS N08020 | Carpenter 20 CB3 Stainless Steel

UNS N08020 | Carpenter 20 CB3 Stainless Steel A Guide to 304 Stainless Steel Tube Sizes

A Guide to 304 Stainless Steel Tube Sizes ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 Super Duplex UNS S32750 / EN 1.4410

Super Duplex UNS S32750 / EN 1.4410 EN 1.4436 / ASTM 316 Stainless Steel

EN 1.4436 / ASTM 316 Stainless Steel ASTM 304L ( EN 1.4307 ) Stainless Steel

ASTM 304L ( EN 1.4307 ) Stainless Steel