10mm vs. 20mm Stainless Steel Plate: Which One Suits Your Project Best?

Introduction

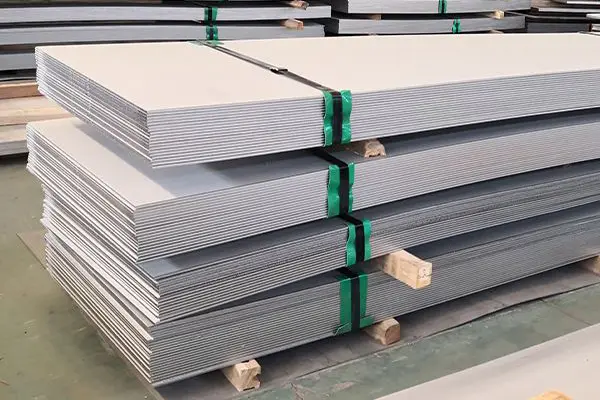

When it comes to construction and manufacturing projects, the materials used can significantly influence the project's success. Among these, stainless steel plates stand out for their durability, resistance to corrosion, and versatility. Available in various thicknesses, each suited for specific applications, choosing the right stainless steel plate is crucial for any project's longevity and efficiency. This article zeroes in on the comparison between 10mm and 20mm stainless steel plates, two commonly used thicknesses that cater to diverse industry needs.

The choice between a 10mm and a 20mm stainless steel plate is not merely a matter of thickness but involves understanding the unique properties that each brings to the table. With their robust composition, these plates offer solutions to a wide array of challenges faced by engineers and architects. Whether it's for structural support, aesthetic purposes, or specialized applications, the decision impacts not only the project's immediate outcomes but also its maintenance and longevity.

Properties of Stainless Steel Plates

When selecting a stainless steel plate for any project, understanding its inherent properties is crucial. Stainless steel, known for its high corrosion resistance, strength, and durability, is an alloy that effectively combines various elements to meet the demands of diverse applications. The properties of stainless steel plates can be significantly influenced by their thickness, with 10mm and 20mm plates being popular choices for a variety of applications.

Durability and Strength : One of the primary considerations when choosing the thickness of a stainless steel plate is its durability and strength. Thicker plates, such as 20mm, inherently possess higher strength and are less prone to deformation under load compared to thinner plates like the 10mm option. This makes 20mm plates an ideal choice for heavy-duty applications where structural integrity is paramount.

Corrosion Resistance : Stainless steel’s corrosion resistance is one of its most valued properties, stemming from the presence of chromium in the alloy. While both 10mm and 20mm plates offer excellent resistance to oxidation and corrosion, the choice of thickness may be influenced by the specific environmental conditions the material will be exposed to. Thicker plates may be preferred in highly corrosive environments to ensure longevity.

Machinability and Weldability : The thickness of the plate can also affect its machinability and weldability. Thinner plates, such as the 10mm option, are generally easier to cut and weld, offering greater flexibility for projects that require intricate shapes and connections. However, with the right equipment and techniques, 20mm plates can also be successfully machined and welded to meet project specifications.

Thermal Conductivity and Heat Resistance : Stainless steel plates are known for their excellent heat resistance, making them suitable for applications involving high temperatures. The thickness of the plate can influence its thermal conductivity, with thicker plates offering better resistance to heat. This property is particularly important in applications such as boilers, heat exchangers, and other equipment exposed to high temperatures.

Cost Considerations : Finally, the cost is a significant factor in the decision-making process. Generally, thicker plates, such as 20mm, will be more expensive than thinner plates like 10mm due to the increased amount of material. However, the decision should also consider the long-term benefits of using a thicker plate, such as enhanced durability and reduced maintenance costs.

In summary, the properties of stainless steel plates, including durability, corrosion resistance, machinability, weldability, thermal conductivity, and cost, are crucial factors to consider when choosing between 10mm and 20mm thicknesses. The selection process should carefully evaluate the specific requirements of the project to determine which thickness best meets the project’s needs.

Applications of 10mm Stainless Steel Plates

The 10mm stainless steel plate offers a unique combination of flexibility and strength, making it an excellent choice for a wide range of applications. This thickness is particularly favored for its ease of handling and installation, along with its sufficient durability for many projects. Here, we explore some of the primary uses and advantages of 10mm stainless steel plates in various industries.

Construction and Architecture : In the construction sector, 10mm stainless steel plates are widely used for structural framing, cladding, and decorative features. Their moderate thickness allows for easier shaping and forming, making them ideal for architectural elements that combine aesthetic appeal with structural integrity. They are also used in the fabrication of bridges, stadiums, and public installations where both durability and appearance are important.

Automotive and Transportation : The automotive industry values 10mm plates for their balance of weight and strength. They are employed in the manufacturing of vehicle chassis, body panels, and in transportation infrastructure such as road barriers and railway tracks. This thickness ensures that the components are robust enough to withstand wear and tear while helping to keep the overall weight of the structure manageable.

Marine Applications : Stainless steel is renowned for its corrosion resistance, making 10mm plates a preferred choice for marine applications. They are used in the construction of ship hulls, decks, and superstructures, offering long-term resistance against the corrosive effects of seawater and marine environments.

Manufacturing Equipment : In manufacturing settings, 10mm stainless steel plates are used in the creation of machinery and equipment. This includes components for food processing machines, chemical tanks, and pharmaceutical devices. The thickness provides a good balance between ease of fabrication and the strength required to withstand the stresses of operational processes.

The versatility of 10mm stainless steel plates makes them a valuable resource across a broad spectrum of industries. Their applications range from structural to decorative, highlighting the material's ability to meet both technical and aesthetic requirements. When selecting a 10mm plate for a project, it is essential to consider the specific demands of the application to ensure that the material's properties align with the project's needs.

Applications of 20mm Stainless Steel Plates

The 20mm stainless steel plate is distinguished by its superior strength and durability, making it an ideal choice for heavy-duty applications. This thickness is particularly well-suited to environments that require high resistance to wear and tear or where structural stability is paramount. Below, we explore the key uses and advantages of 20mm stainless steel plates across various sectors.

Heavy Industry and Construction : In heavy industrial and construction projects, the robustness of 20mm plates is invaluable. These plates are frequently used in the construction of high-rise buildings, industrial facilities, and infrastructure projects such as bridges and tunnels. Their ability to bear significant loads and resist bending or deformation under stress makes them a staple in structures demanding extreme durability.

Shipbuilding and Offshore Platforms : The marine environment poses unique challenges, including constant exposure to corrosive seawater and extreme pressures. 20mm stainless steel plates are widely employed in shipbuilding and the construction of offshore oil rigs and platforms. Their thickness provides the necessary strength to withstand harsh marine conditions and support the substantial weight of these structures.

Mining and Resource Extraction : The mining sector relies on equipment and infrastructure that can endure abrasive conditions and heavy usage. 20mm stainless steel plates are used in the fabrication of mining machinery, conveyance systems, and structural components of extraction facilities. Their wear resistance ensures longevity and reliability in environments where durability is critical.

Pressure Vessels and Tanks : For industries dealing with high-pressure processes, such as chemical, petrochemical, and pharmaceutical manufacturing, 20mm plates offer the strength required to safely contain gases and liquids. These plates are used in the construction of pressure vessels, storage tanks, and reactors, where their ability to withstand high pressures and corrosive materials is essential.

The applications of 20mm stainless steel plates highlight their importance in projects where strength, durability, and resistance to environmental conditions are paramount. Their use in such a wide range of industries underscores the versatility of stainless steel as a material capable of meeting the most demanding requirements.

Choosing the Right Thickness for Your Project

Deciding between a 10mm and a 20mm stainless steel plate is a critical choice that can significantly affect the success and longevity of your project. This decision should be guided by a comprehensive understanding of the project’s requirements and the unique benefits each thickness offers. Here are some factors to consider when selecting the appropriate thickness for your stainless steel plate:

1.Assess the Project’s Structural Needs : The primary consideration should be the structural demands of your project. For applications requiring high strength and durability, especially where there is a significant load-bearing requirement, 20mm plates are generally preferable. Conversely, for projects where flexibility and ease of fabrication are priorities, 10mm plates might be more suitable.

2.Consider Environmental Conditions : The environment in which the stainless steel will be used plays a crucial role in deciding the thickness. For harsh, corrosive environments, such as marine or industrial settings, opting for a thicker plate can offer longer service life and better resistance to wear and tear.

3.Evaluate Cost Implications : Budget constraints are always a consideration in project planning. While 20mm plates offer greater durability, they also come at a higher material cost. Analyze whether the benefits of a thicker plate justify the additional expense in the context of your project’s overall budget and long-term maintenance costs.

4.Understand Fabrication Requirements : The complexity of the project's design and fabrication needs should influence the choice of thickness. Thinner plates, like the 10mm option, are generally easier to cut, weld, and form, providing greater versatility for intricate designs.

5.Longevity and Maintenance : Consider the expected lifespan of the project and any maintenance requirements. Thicker stainless steel plates might offer advantages in terms of reduced maintenance needs and longer overall lifespan, particularly in demanding applications.

Making the right choice between 10mm and 20mm stainless steel plates involves balancing these factors against the project’s specific needs. It’s also beneficial to consult with engineers and material specialists to leverage their expertise in making the most appropriate selection.

Conclusion

In conclusion, the decision to use a 10mm or a 20mm stainless steel plate should be based on a thorough assessment of the project's requirements, environmental conditions, budget, and design complexities. By carefully weighing these considerations, you can ensure that your project benefits from the optimal balance of strength, durability, and cost-effectiveness.