Titanium Gr.12 is an alloy of Ti, Ni, Pd and Mo that provides more strength than Titanium Gr.2 while remaining resistant to acid and crevice corrosion in hot brine environments. Its elevated strength allows the use of thinner wall thicknesses than those of Titanium Gr.2 and Gr.7 under comparable conditions.

| Chemical Composition |

0.08C-0.2~0.4Mo-0.6~0.9Ni-0.03N-0.03Fe-0.25O-0.015H-(rest)Ti |

| Physical Property |

• Tensile Strength: 483Mpa

• Yield Strength: 345 MPa

• Elongation: 18% |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

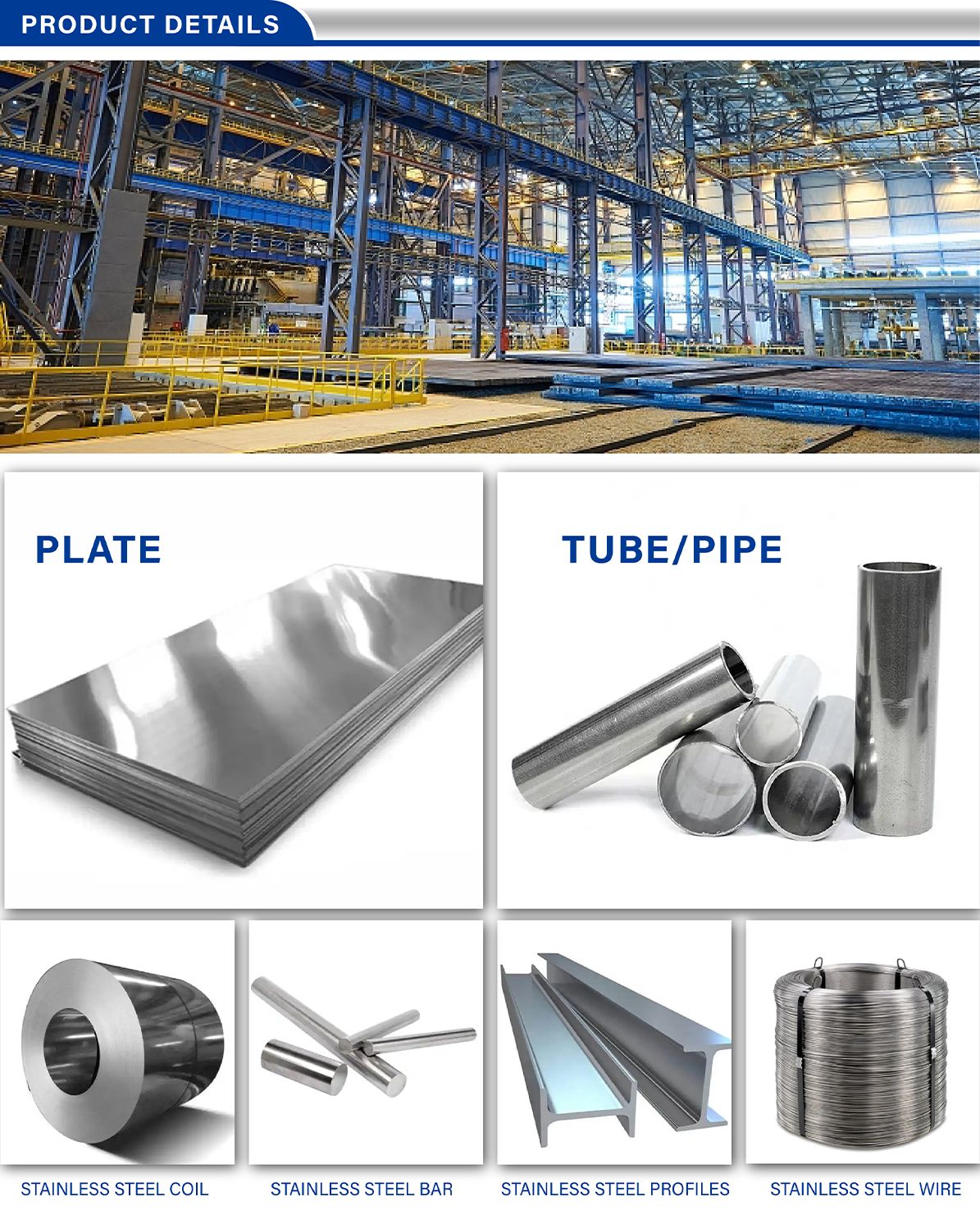

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Titanium Alloy Grade 12 has outstanding corrosion resistance and a combination of high strength and low density, with good ductility.

UNS R53400 is primarily used for chemical processing and seawater applications requiring moderate strength and enhanced corrosion resistance such as heat exchangers, pressure vessels, chlorine equipment, nuclear power plant, and salt evaporators. Grade 12 titanium finds its use with media either mildly reducing or vary between oxidizing and reducing.

Application:

- Pumps

- Valves

- Heat exchangers

- Pipes and fittings

- Chemical processing

- In high temperature chemical manufacturing equipment

- Marine and airframe components

- In medium reducing or variable oxidizing-reducing media - containers

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel AISI 444 Stainless Steel | EN 1.4521 Stainless Steel

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel A Guide to 304 Stainless Steel Tube Sizes

A Guide to 304 Stainless Steel Tube Sizes ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 Ti Gr.7 / 3.7235

Ti Gr.7 / 3.7235 Super Duplex UNS S32750 / EN 1.4410

Super Duplex UNS S32750 / EN 1.4410 Martensitic Stainless Steel X39CrMo17-1 / 1.4122

Martensitic Stainless Steel X39CrMo17-1 / 1.4122 10mm vs. 20mm Stainless Steel Plate: Which One Suits Your Project Best?

10mm vs. 20mm Stainless Steel Plate: Which One Suits Your Project Best?