ASTM 436 and EN 1.4513 are molybdenum modified, heat-resistant ferritic stainless steels. They offer improved ductility and a greater ability to withstand mechanical stresses at elevated temperatures. These steels are ideal for use in elevated-temperature applications such as automotive components.

| Chemical Composition |

16.0 – 18.0Cr, 0.9 |

| Physical Property |

• Density: 7.7 g/cm³

• Electrical resistance: 0.60 μΩ·m

• Thermal conductivity: 23 W/(m·K)

• Specific heat: 460 J/(kg·K)

• Young's modulus: 220 GPa

• 0.2% Yield stress: 240 MPa, min |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

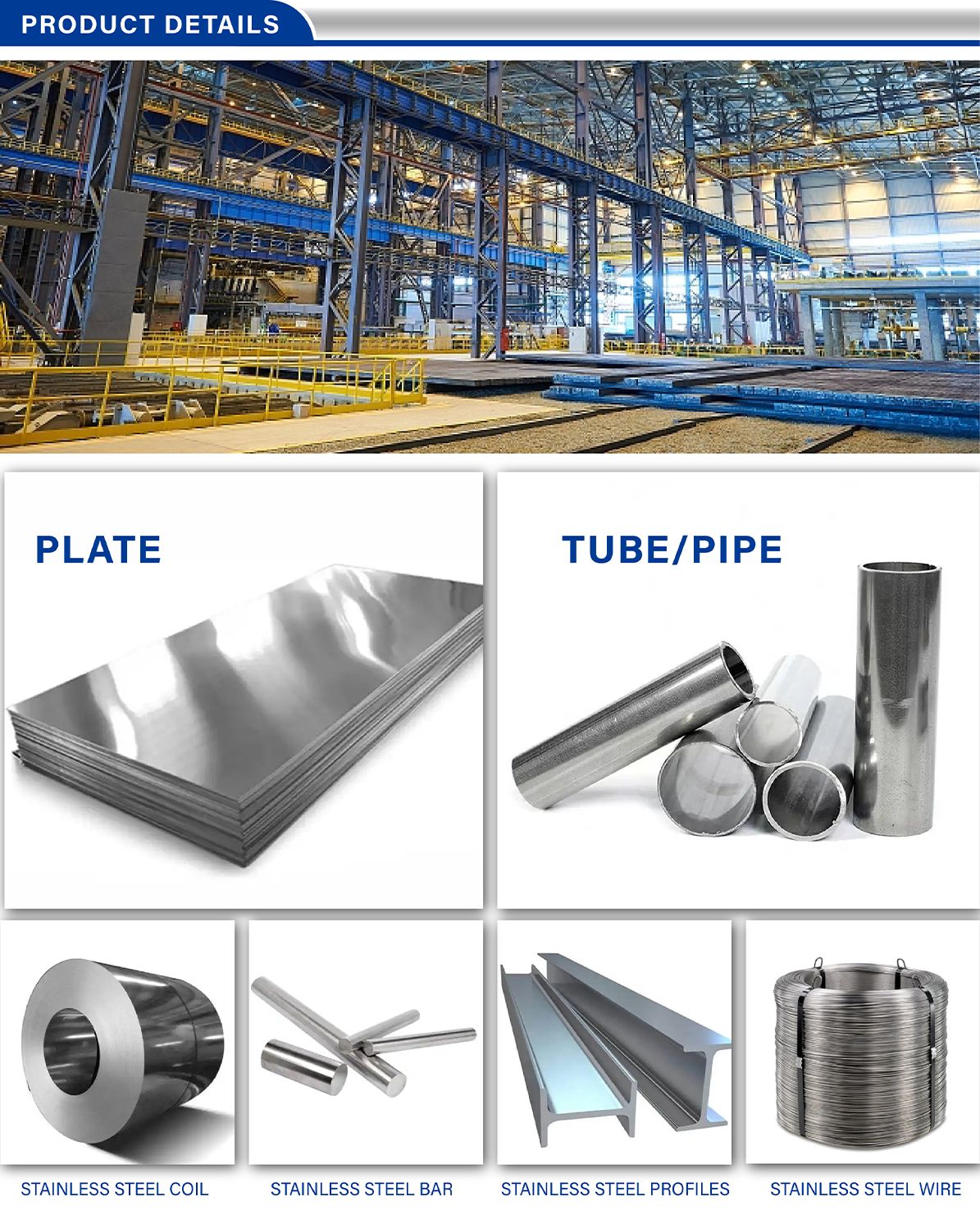

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

AISI/ASTM 436: Excellent general corrosion resistance (under conditions typical of car exhaust systems), i.e. against pitting corrosion (comparable to 1.4301), stress corrosion cracking and intergranular corrosion as well as oxidation (up to 850 °C); good formability and weldability; low coefficient of thermal expansion; high thermal conductivity (resulting in an even appearance)

Application:

- Heat exchangers

- Acid and nitrogen oxide pipelines

- Acid storage tanks

- Acid transport tanks

- Dairy, fruit and vegetable and brewery industries

- Textile industry

- Household appliances

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 EN 1.4436 / ASTM 316 Stainless Steel

EN 1.4436 / ASTM 316 Stainless Steel ASTM 304L ( EN 1.4307 ) Stainless Steel

ASTM 304L ( EN 1.4307 ) Stainless Steel ASTM 310S - EN 1.4845

ASTM 310S - EN 1.4845 ASTM 309S - EN 1.4833

ASTM 309S - EN 1.4833 ASTM 439 - EN 1.4510

ASTM 439 - EN 1.4510 ASTM 434 - EN 1.4113

ASTM 434 - EN 1.4113