Stainless Steel 309S Welded Pipes boast superior oxidation/corrosion resistance due to their high chromium content and excellent/durable room temperature strength, surpassing alloy 304. Additionally, these pipes demonstrate remarkable heat-resistance.

| Chemical Composition |

0.06C-22.3Cr-12.6Ni |

| Physical Property |

• Density: 7.89 g/cm³

• Tensile Strength: 620 MPa

• Yield Strength: 300 MPa

• Specific Heat: 502 J/kg-°k (0 – 100 ℃)

• Melting Range: 1480 – 1530 ℃

• Electrical Resistivity: 78 Microhm-cm at 20 ℃ |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

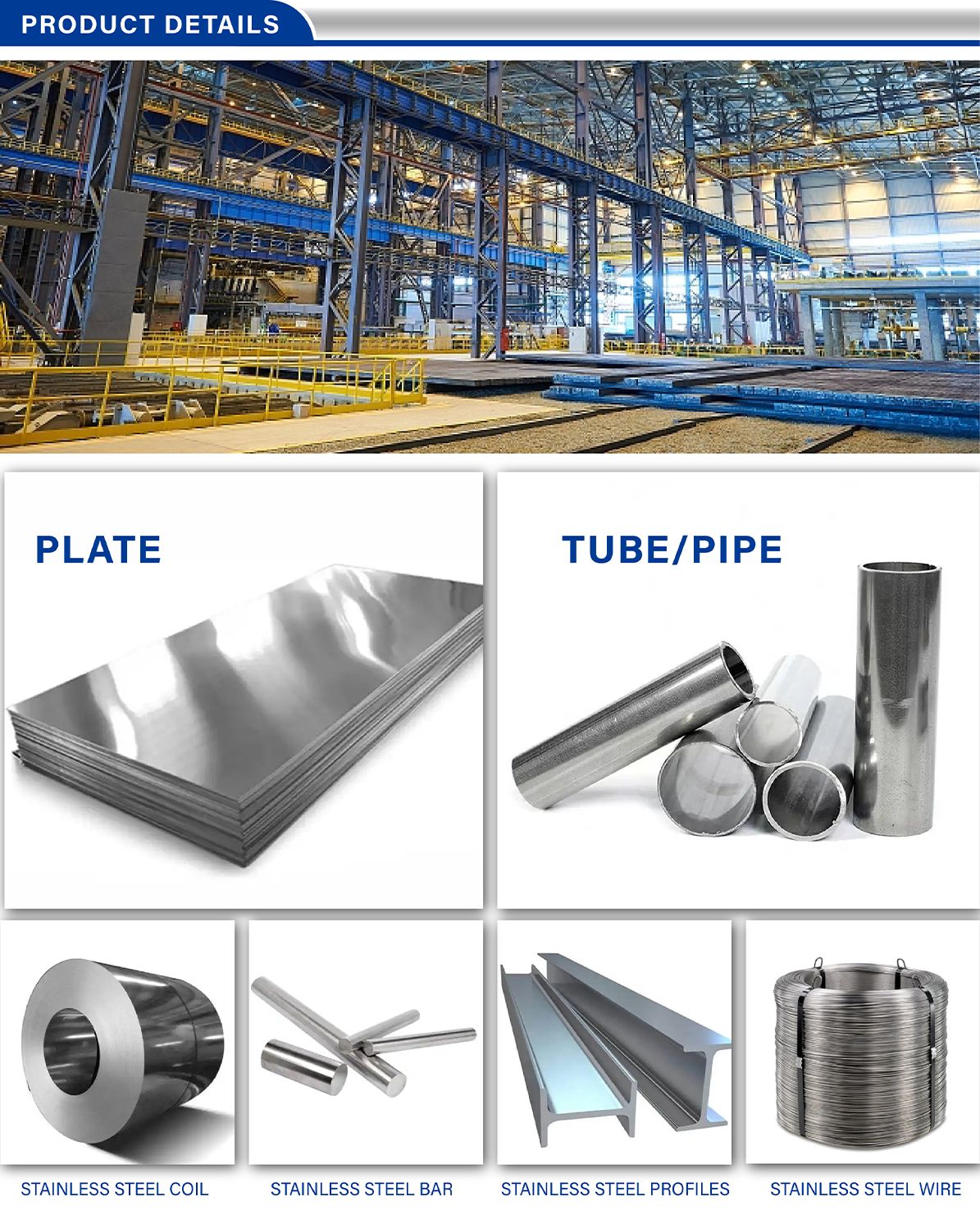

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Alloy 309/309S (UNS S30900/S30908) austenitic stainless steel is typically used for elevated temperature applications. Its high chromium and nickel content provides comparable corrosion resistance, superior resistance to oxidation, and the retention of a larger fraction of room temperature strength than the common austenitic Alloy 304.

Application:

- Industrial furnaces

- Annealing bells

- Heat exchangers

- Salt bath treatment equipment

- Calrods

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 EN 1.4436 / ASTM 316 Stainless Steel

EN 1.4436 / ASTM 316 Stainless Steel ASTM 304L ( EN 1.4307 ) Stainless Steel

ASTM 304L ( EN 1.4307 ) Stainless Steel ASTM 310S - EN 1.4845

ASTM 310S - EN 1.4845 ASTM 439 - EN 1.4510

ASTM 439 - EN 1.4510 ASTM 434 - EN 1.4113

ASTM 434 - EN 1.4113 ASTM 321 - EN 1.4541

ASTM 321 - EN 1.4541