Titanium Grade 7 (3.7235) is a highly specialized alloy known for its exceptional corrosion resistance and mechanical properties. This section provides a comprehensive overview of its specifications, chemical composition, mechanical properties, and the industry standards it meets or exceeds.

Features of Titanium Grade 7

- High Corrosion Resistance: Ti Gr.7 is exceptionally resistant to a wide range of corrosive environments, including chlorides, acids, and saline solutions. The addition of palladium significantly enhances its corrosion resistance, particularly in reducing environments.

- Excellent Durability: This alloy demonstrates superior durability and longevity, maintaining its integrity and performance over extended periods, even in harsh conditions.

- Outstanding Strength-to-Weight Ratio: Titanium Grade 7 offers a high strength-to-weight ratio, combining lightweight characteristics with robust mechanical strength.

- Good Weldability and Fabricability: Despite its strength, Ti Gr.7 can be efficiently welded and fabricated into various forms, making it versatile for complex designs.

- Enhanced Resistance to Erosion and Wear: The material's toughness and hardness confer excellent resistance to erosion and wear, crucial for moving parts and high-flow environments.

Titanium Grade 7 Chemical Composition

Titanium Grade 7's chemical composition is carefully controlled to ensure its superior performance in various applications. The key components include:

| Ti |

Pd |

N |

Fe |

O |

H |

C |

| ca % |

% |

% |

% |

% |

% |

% |

| 99.3 |

0.12-0.2 |

0.05 |

0.25 |

0.18 |

0.013 |

0.06 |

Mechanical Properties of Ti Gr.7

| Physical Property |

• Tensile Strength: 345Mpa

• Yield Strength: 275-450 MPa

• Elongation: 20% |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

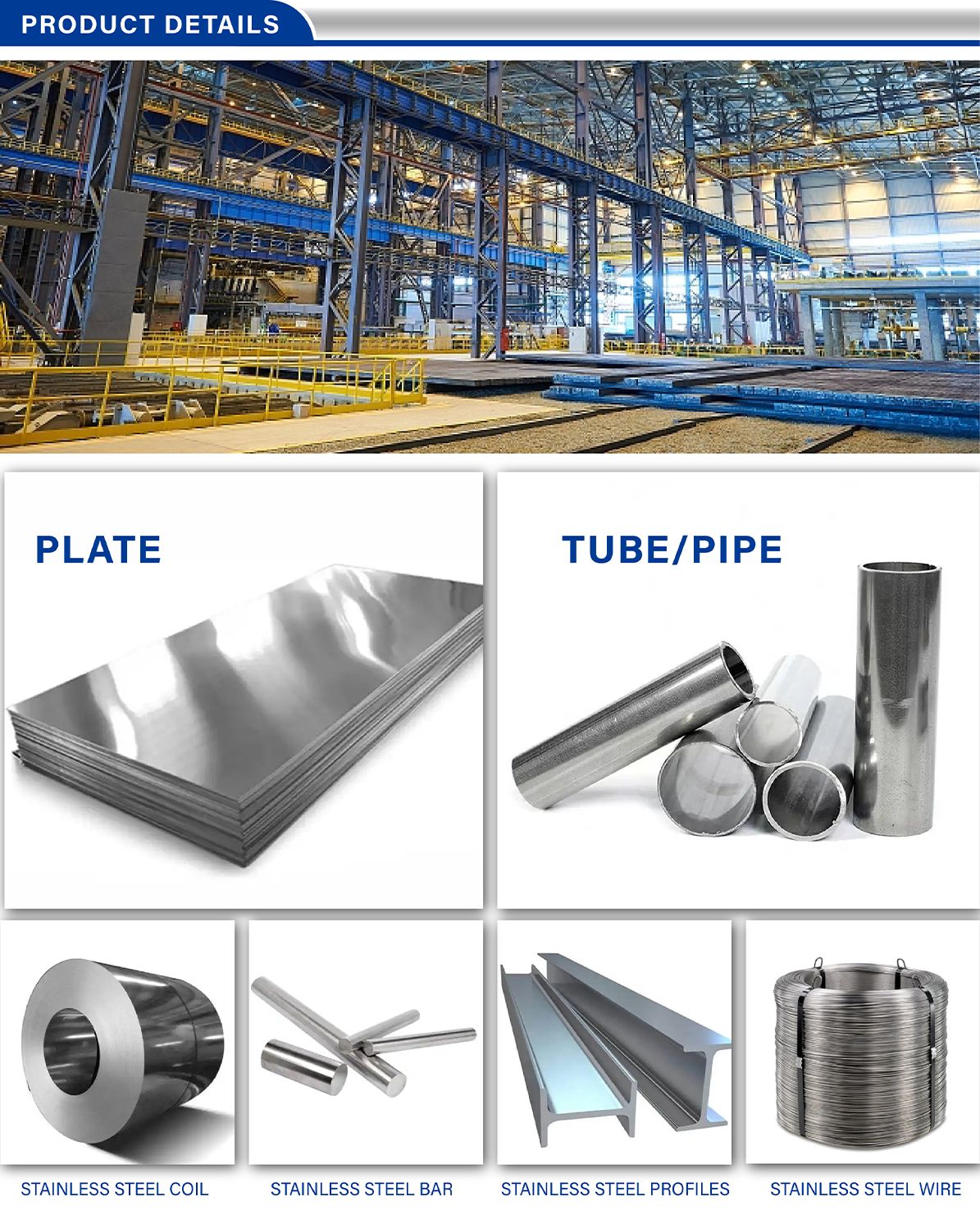

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Industry Standards and Certifications

Ti Gr.7 / 3.7235 meets or exceeds several critical industry standards and certifications, underscoring its reliability and quality:

- ASTM B265 (Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate)

- ASTM B338 (Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers)

- ASTM B348 (Standard Specification for Titanium and Titanium Alloy Bars and Billets)

- ASTM B367 (Standard Specification for Titanium and Titanium Alloy Castings)

- NACE MR0175/ISO 15156 for use in sour service environments

These standards ensure that Ti Gr.7 / 3.7235 is suitable for a wide range of applications, from chemical processing equipment to aerospace components, providing a benchmark for performance and quality in the industry.

Comparative Analysis

- Corrosion Resistance: Titanium Grade 7 offers superior corrosion resistance in more aggressive environments, such as those containing chlorides and other corrosive chemicals, where stainless steel might succumb to pitting or crevice corrosion.

- Strength-to-Weight Ratio: Ti Gr.7 has a higher strength-to-weight ratio compared to 316 stainless steel, making it ideal for applications where strength is critical but weight is a limiting factor.

- Cost and Longevity: While stainless steel might be less expensive upfront, Ti Gr.7's longer lifespan and lower maintenance requirements can make it more cost-effective over time, especially in harsh environments.

- Corrosion Resistance: Titanium Grade 7 significantly outperforms aluminum alloys in terms of corrosion resistance, especially in saline or high-temperature environments.

- Strength at High Temperatures: Unlike aluminum alloys, which can lose strength at elevated temperatures, Ti Gr.7 maintains its strength and mechanical properties even at high temperatures.

- Weight: Although both materials are known for their lightweight properties, titanium provides a better strength-to-weight ratio, crucial for aerospace and automotive applications.

Comparison Chart

| Property |

Titanium Grade 7 |

Stainless Steel 316 |

Aluminum Alloys |

| Corrosion Resistance |

Superior |

High |

Moderate |

| Strength-to-Weight Ratio |

Excellent |

Good |

Good |

| High-Temperature Strength |

High |

Moderate |

Low |

| Biocompatibility |

Excellent |

Good |

Moderate |

| Cost-Effectiveness |

High (long-term) |

Moderate |

High |

Application:

- Chemical process and production equipment components

- Corrosive Chemical Equipment

- Hydrocarbon processing

- Diesel Engine Parts

- Exhaust guard

- Fastener

- Mixer

- Cooler

- Shipping Corrosion Resistant Piping, Valves, Pumps

- Seawater desalination system components

- Aircraft skeleton

- Military industry

- Precision manufacturing

Benefits in Practical Applications

- Chemical Processing Equipment: Ti Gr.7's high corrosion resistance ensures longevity and reliability in aggressive chemical environments, reducing maintenance costs and downtime for equipment such as reactors, heat exchangers, and piping systems.

- Aerospace and Marine Engineering: The alloy's strength-to-weight ratio and durability contribute to weight reduction and enhanced performance in aerospace structures and marine vessels, leading to fuel savings and improved efficiency.

- Medical Devices: Its biocompatibility and resistance to bodily fluids make Ti Gr.7 an excellent choice for implants, surgical instruments, and other medical devices, ensuring patient safety and device longevity.

- Environmental and Waste Management Systems: The material's resistance to corrosion and wear is beneficial in waste treatment and environmental protection equipment, where reliability and resistance to harsh conditions are paramount.

- Energy Production: In power generation, especially in geothermal, hydroelectric, and offshore wind installations, Ti Gr.7's durability and corrosion resistance ensure the longevity and reliability of components exposed to corrosive elements and high-stress conditions.

(FAQ) about Titanium Grade 7 (3.7235)

1.What Makes Titanium Grade 7 Superior in Corrosion Resistance?

Titanium Grade 7 (3.7235) is renowned for its exceptional corrosion resistance, primarily due to the palladium content (0.12 to 0.25%). This addition enhances its ability to withstand corrosive attacks in environments that would typically compromise other materials, including highly acidic conditions and saline solutions. Unlike many other metals, Ti Gr.7 forms a stable, passive oxide layer when exposed to oxygen, protecting the underlying metal from further degradation. This characteristic makes it ideal for chemical processing, marine, and aerospace applications where durability and longevity are crucial.

2.Can Titanium Grade 7 Be Used in Medical Applications?

Yes, Titanium Grade 7 is highly suitable for medical applications due to its excellent biocompatibility, resistance to bodily fluids, and corrosion resistance. Its non-toxicity and ability to withstand the harsh sterilization processes make it ideal for implants, surgical instruments, and other medical devices. The alloy's palladium content further enhances its corrosion resistance, important in the physiological environment. Consequently, Ti Gr.7 is often chosen for critical medical applications where material performance can directly impact patient outcomes.

3. How to Order Titanium Grade 7 and What Is the Lead Time?

Ordering Titanium Grade 7 typically involves contacting the supplier directly to discuss specifications, quantities, and any custom requirements. The lead time for Ti Gr.7 can vary based on factors such as the complexity of the order, current stock levels, and production schedules. It's essential to provide detailed specifications and intended applications to ensure the material meets your needs. Suppliers often offer assistance with material selection and can provide estimates on lead times and pricing. For specific projects, early consultation with the supplier is recommended to align production timelines and material availability.

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel AISI 444 Stainless Steel | EN 1.4521 Stainless Steel

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel A Guide to 304 Stainless Steel Tube Sizes

A Guide to 304 Stainless Steel Tube Sizes ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 Super Duplex UNS S32750 / EN 1.4410

Super Duplex UNS S32750 / EN 1.4410 Martensitic Stainless Steel X39CrMo17-1 / 1.4122

Martensitic Stainless Steel X39CrMo17-1 / 1.4122 10mm vs. 20mm Stainless Steel Plate: Which One Suits Your Project Best?

10mm vs. 20mm Stainless Steel Plate: Which One Suits Your Project Best? EN 1.4436 / ASTM 316 Stainless Steel

EN 1.4436 / ASTM 316 Stainless Steel