UNS S32750, classified as a super duplex stainless steel, is renowned for its exceptional combination of strength and corrosion resistance. This grade is specifically engineered to withstand harsh environments, making it an ideal choice for critical applications across a variety of industries.

Characteristics

- Enhanced Corrosion Resistance: Thanks to its high chromium, molybdenum, and nitrogen content, UNS S32750 exhibits superior resistance to a wide range of corrosion mechanisms, including pitting, crevice corrosion, and stress corrosion cracking.

- High Strength: The duplex structure of UNS S32750 provides a high yield strength, nearly double that of conventional austenitic stainless steels, which enables the design of lighter, more durable structures.

- Excellent Weldability and Formability: Despite its high strength, UNS S32750 can be welded and formed easily, making it versatile for various manufacturing processes.

Common Applications

- Offshore oil and gas exploration and production equipment where high strength and corrosion resistance are essential.

- Seawater and brackish water handling systems where chloride-induced corrosion is a concern.

- Chemical processing equipment in aggressive chloride-bearing environments.

- Flue gas desulfurization systems in power plants.

UNS S32750 Chemical Composition

The chemical composition of UNS S32750 is carefully balanced to provide the desired mechanical and corrosion-resistant properties:

- Chromium (Cr): 24.0 - 26.0%

- Nickel (Ni): 6.0 - 8.0%

- Molybdenum (Mo): 3.0 - 5.0%

- Nitrogen (N): 0.24 - 0.32%

- Manganese (Mn): Max 1.20%

- Silicon (Si): Max 0.80%

- Carbon (C): Max 0.030%

- Phosphorous (P): Max 0.035%

- Sulfur (S): Max 0.020%

- Others: Iron (Fe) as the balance, along with trace amounts of copper (Cu) and others to enhance specific properties.

Mechanical Properties of UNS S32750

The chemical composition of X39CrMo17-1 / 1.4122 is carefully balanced to provide optimal properties:

| Physical Property |

• Density: 7.80 g/cc

• Tensile Strength: 830 MPa

• Yield Strength:590 MPa

• Modulus of Elasticity: 200 GPa

• Thermal Conductivity: 15.0 W/m-K |

| Stock & Dimensions |

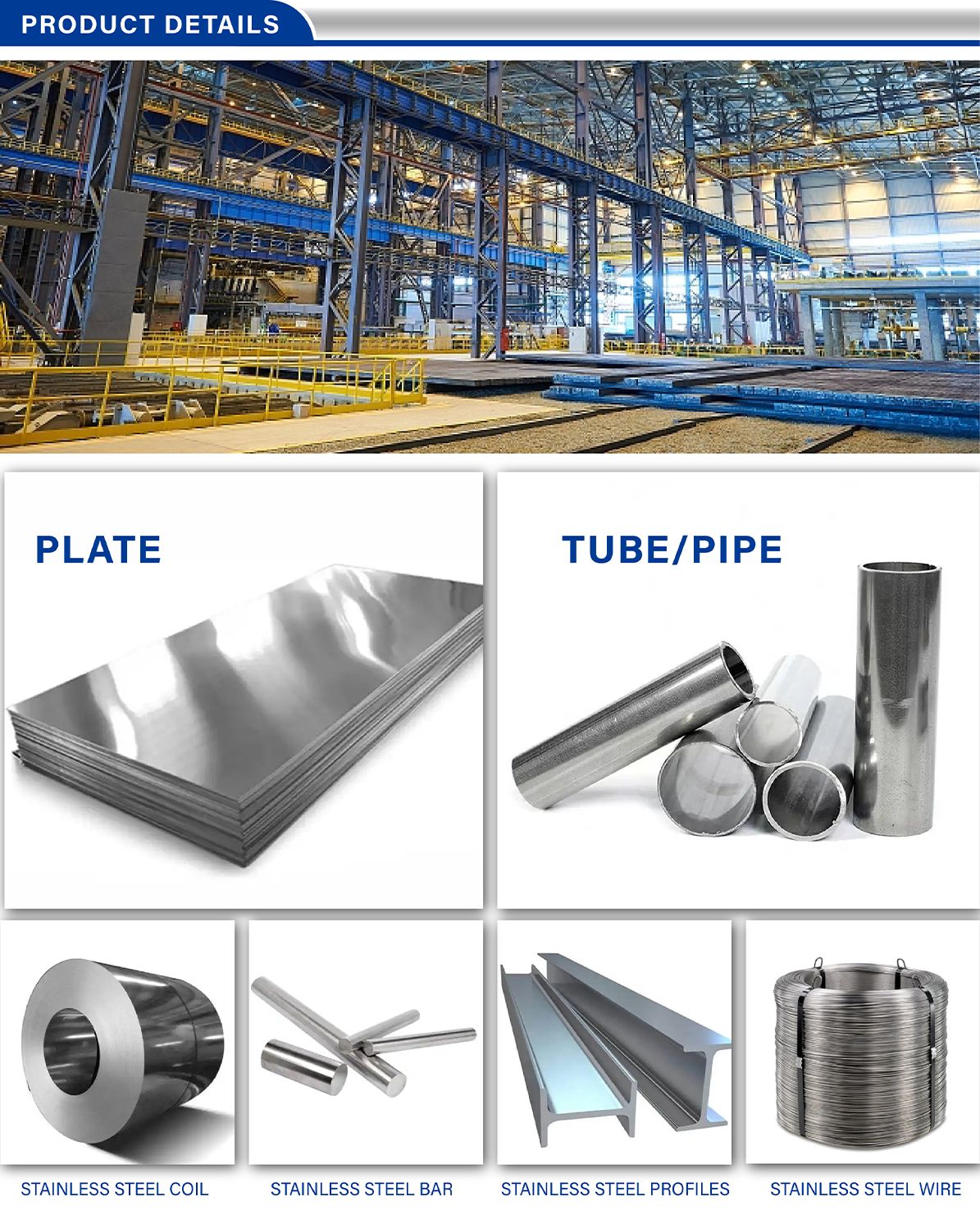

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

UNS S32760 vs. UNS S32750

When comparing UNS S32760 and UNS S32750, it's important to note that both belong to the family of super duplex stainless steels, offering similar advantages in terms of strength and corrosion resistance. However, there are key differences that make each grade suitable for specific applications.

Key Differences

- Chemical Composition: UNS S32760 contains slightly higher copper and tungsten levels, which enhance its resistance to certain types of corrosion.

- Mechanical Properties: While both grades have high strength, UNS S32760 typically offers a slightly higher yield strength than UNS S32750.

- Corrosion Resistance: UNS S32760's enhanced chemical composition provides it with slightly better resistance to localized corrosion than UNS S32750.

Applications

- UNS S32750 is often used in high-chloride environments, such as seawater applications, due to its excellent resistance to chloride pitting and crevice corrosion.

- UNS S32760, with its slightly higher mechanical strength and corrosion resistance, is suitable for more extreme conditions, including highly corrosive environments and areas where abrasion and wear resistance are essential.

Both grades ensure that engineering projects can achieve their durability and longevity goals, making them ideal for the most demanding applications in the oil and gas, chemical processing, and marine industries.

Advantages of Using UNS S32750 (EN 1.4410)

The use of UNS S32750 in various industrial applications comes with a host of benefits, primarily due to its superior mechanical and chemical properties. Here are some of the key advantages:

- Exceptional Corrosion Resistance: UNS S32750 offers outstanding resistance to chloride-induced pitting and crevice corrosion, surpassing the performance of many other stainless steels. This makes it an ideal choice for marine environments and applications exposed to harsh chemical conditions.

- High Strength: With a yield strength more than double that of standard austenitic stainless steels, UNS S32750 allows for the design of lighter structures without compromising on durability or reliability.

- Excellent Durability: The combination of high tensile strength and excellent corrosion resistance ensures that components made from UNS S32750 withstand the test of time, even in the most challenging environments.

- Good Weldability and Formability: Despite its strength, UNS S32750 can be welded and formed using standard techniques, which is not always the case with high-strength materials. This versatility makes it suitable for a wide range of applications.

FAQs on X39CrMo17-1 / 1.4122

1.How does UNS S32750 compare to 316L stainless steel in terms of corrosion resistance?

UNS S32750 super duplex stainless steel offers superior corrosion resistance compared to 316L stainless steel, especially in environments with high chloride levels, such as seawater and chloride-bearing media. Its higher chromium, molybdenum, and nitrogen content provide enhanced protection against pitting, crevice corrosion, and stress corrosion cracking. This makes UNS S32750 an ideal choice for applications in marine, chemical processing, and other harsh environments where 316L might fail prematurely due to corrosion.

2.Can UNS S32750 be used in high-temperature applications?

Yes, UNS S32750 is suitable for use in high-temperature applications. It can withstand temperatures up to 300°C (572°F) while maintaining its mechanical strength and corrosion resistance. This capability is due to its balanced duplex microstructure and high chromium, molybdenum, and nitrogen content. However, for applications above this temperature range, it's important to consult technical data sheets or a material specialist to ensure the alloy's stability and performance in the specific operating conditions.

3.Is UNS S32750 suitable for use in seawater applications?

Absolutely, UNS S32750 is exceptionally suitable for use in seawater applications. Its high resistance to chloride-induced corrosion, including pitting, crevice corrosion, and stress corrosion cracking, makes it an excellent material choice for marine environments, desalination plants, and other seawater-related applications. Its durability and long service life in aggressive chloride-containing environments help minimize maintenance and replacement costs, making it a cost-effective solution for seawater exposure.

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel

ALLOY 24 ( UNS S34565 / EN 1.4565 ) Stainless Steel UNS N08020 | Carpenter 20 CB3 Stainless Steel

UNS N08020 | Carpenter 20 CB3 Stainless Steel UNS S32304 - EN 1.4362

UNS S32304 - EN 1.4362 UNS S31200 - EN 1.4460

UNS S31200 - EN 1.4460 UNS S30430 - EN 1.4567

UNS S30430 - EN 1.4567 UNS S31050 - EN 1.4466

UNS S31050 - EN 1.4466 UNS S32760 - EN 1.4501

UNS S32760 - EN 1.4501 UNS S30900 - EN 1.4828

UNS S30900 - EN 1.4828