ASTM 304L / EN 1.4307 Stainless Steel Features and Benefits

1.Corrosion Resistance: Its high chromium and nickel content provides exceptional resistance to a wide range of corrosive environments, including those involving various acids and bases. This makes it ideal for use in harsh chemical processing environments as well as in food and beverage processing where cleanliness and hygiene are paramount.

2.Weldability and Formability: The low carbon content significantly reduces the risk of carbide precipitation at the grain boundaries during welding, thereby maintaining its corrosion resistance in the welded state. This feature, combined with its excellent formability, makes it highly suitable for various manufacturing processes, including complex formed parts and welded structures.

3.Durability and Longevity: ASTM 304L / EN 1.4307 is known for its durability and ability to withstand prolonged exposure to harsh environments without significant degradation. This longevity is crucial in applications where long-term reliability and minimal maintenance are desired, such as in architectural facades, medical devices, and outdoor equipment.

ASTM 304L Chemical Composition

- Chromium (Cr): 18.0% - 20.0% , which provides excellent resistance to a wide range of chemicals and atmospheric environments.

- Nickel (Ni): 8.0% - 12.0% , enhancing its corrosion resistance, formability, and weldability.

- Carbon (C): Maximum 0.03% , a reduced amount that minimizes carbide precipitation during welding, thereby preserving corrosion resistance in welded structures.

- Manganese (Mn): Up to 2.0% , which contributes to strength and hardness.

- Silicon (Si): Up to 1.0% , used for deoxidation.

- Phosphorus (P): Up to 0.045% , improving strength.

- Sulfur (S): Up to 0.03% , which increases machinability.

ASTM 304L Properties

| Physical Property |

• Density: 7.9 g/cm³

• Tensile Strength: 580 MPa

• Yield Strength: 200 MPa

• Modulus of elasticity: 200 GPa

• Thermal exp. at 100 °C: 16.0 10-6/°C

• Thermal Conductivity: 15 W/m°C |

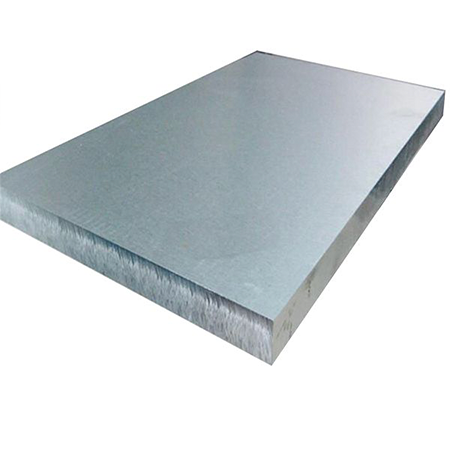

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

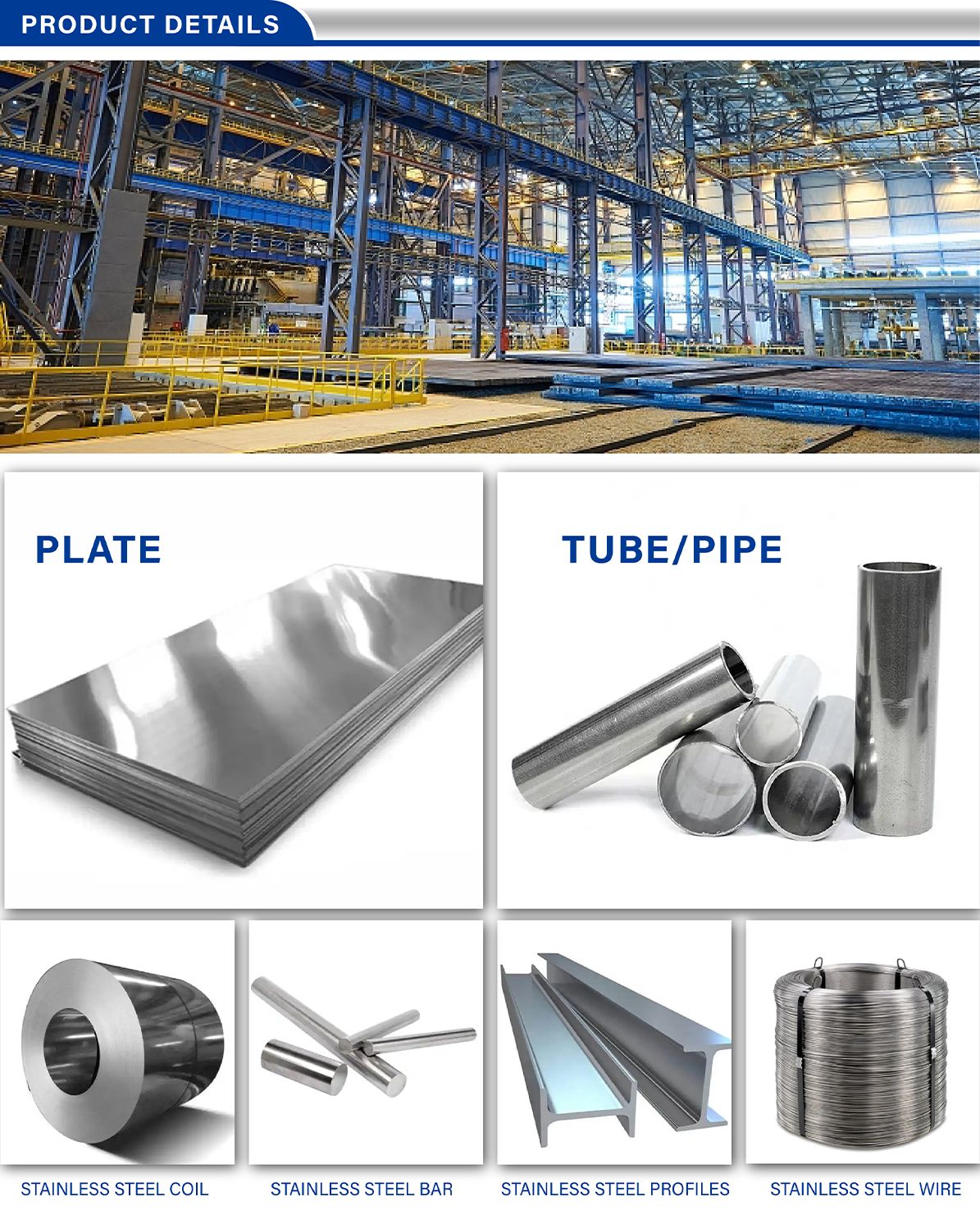

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

The steel grade 1.4307, commonly referred to as ASTM 304/304L or SS2333, is a widely utilized stainless steel, renowned for its balanced composition that confers excellent general properties. Often designated as an 18-8 steel, this grade epitomizes the optimal blend of 18% chromium and 8% nickel, ensuring superior corrosion resistance, robust impact strength, and remarkable formability.

Enhanced with MAXIVAL® technology, 1.4307 steel boasts significantly improved machinability, making it an ideal candidate for the fabrication of corrosion-resistant products through various machining processes. This grade exhibits outstanding resistance to uniform corrosion and performs well against a broad spectrum of mildly corrosive organic and inorganic compounds. Initially non-magnetic, 1.4307 can exhibit slight magnetic properties following extensive cold working or welding procedures, a characteristic that does not detract from its overall performance and utility.

This comprehensive profile underscores the versatility and reliability of 1.4307 (ASTM 304/304L - SS2333) as a foundational material for a diverse array of applications, particularly where corrosion resistance and mechanical integrity are paramount.

EN 1.4307 Typical Applications:

| Application | Advantages | Disadvantages | Considerations | Additional Insights |

|---|

| Construction | Excellent corrosion resistance; durable in various environments | Higher cost compared to some other construction materials | Choose appropriate finishes to enhance corrosion resistance | Ideal for exterior cladding, roofing, and structural supports |

| Building | Aesthetic appeal; maintains appearance over time | Requires proper installation to avoid crevice corrosion | Consider insulation requirements to prevent thermal bridging | Used in facades, door frames, and architectural details |

| Reinforcement | High tensile strength; does not corrode like carbon steel | Costlier than traditional reinforcement materials | Use where corrosion could compromise structural integrity | Often utilized in corrosive environments like coastal areas |

| Machining | Improved machinability with MAXIVAL®; good surface finish | Work hardening can occur, requiring specific machining parameters | Utilize appropriate cutting tools and speeds | Suitable for precision components in industrial equipment |

| Bolts | Strong, with good tensile strength; resistant to loosening from corrosion | Can be more expensive than carbon steel bolts | Select correct grades and sizes for specific applications | Critical for environments demanding high corrosion resistance |

| Fittings | Leak-proof and corrosion-resistant; suitable for harsh chemicals | Initial higher investment compared to standard fittings | Ensure compatibility with the piping material and fluid type | Essential for chemical, food processing, and marine applications |

Recommendations for Storage and Transportation

1.Storage Conditions: : Store stainless steel in a clean, dry area to prevent contamination and corrosion. If possible, keep it indoors to avoid exposure to harsh weather conditions that could cause surface damage. Separate different steel grades to avoid galvanic corrosion.

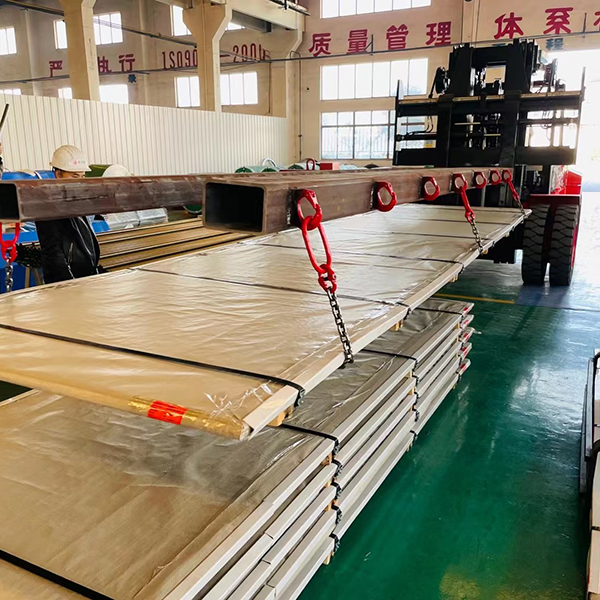

2.Protective Packaging: : Use protective packaging, such as plastic wraps or coatings, to shield the steel surfaces from scratches and environmental elements during storage and transportation. Ensure that the packaging materials are suitable for stainless steel and do not trap moisture against the metal.

3.Transportation Methods: : Securely fasten stainless steel loads on transport vehicles to prevent movement that could cause damage or deformation. Use padding materials to protect edges and surfaces from impact and abrasion.

4.Handling During Transportation: : Use appropriate equipment, such as cranes and forklifts, for loading and unloading. Train personnel in the safe handling of stainless steel products to minimize the risk of accidents and material damage.

(FAQ) About ASTM 304L / EN 1.4307 Stainless Steel

1. What Makes ASTM 304L Different from ASTM 304 Stainless Steel?

ASTM 304L stainless steel is a low-carbon variant of ASTM 304, with a maximum carbon content of 0.03%. This reduction in carbon content minimizes carbide precipitation during welding, preserving the corrosion-resistant properties of the metal in welded joints. The lower carbon content in ASTM 304L enhances its welding and forming capabilities, making it suitable for use in environments where welding is prevalent and corrosion resistance is critical, without the need for post-weld annealing.

2.What Grade is 1.4307 Equivalent to?

The steel grade 1.4307 is equivalent to ASTM 304L, both representing a low-carbon version of the widely used 304 stainless steel. This adjustment to a maximum of 0.03% carbon content enhances weldability by reducing carbide precipitation risks and maintaining corrosion resistance in welded sections. Ideal for projects requiring extensive welding, 1.4307 / ASTM 304L offers a mix of strength, corrosion resistance, and ease of fabrication. This equivalence ensures consistent quality and performance across various applications in engineering and architecture./p>

3.Is ASTM 304L Stainless Steel Magnetic?

In its annealed state, ASTM 304L stainless steel is essentially non-magnetic. However, it may exhibit slight magnetic properties after cold working, such as forming, bending, or welding, due to the formation of martensite in its structure. This magnetism is generally weak and can vary depending on the amount and type of cold work performed on the material.

Customer Reviews for XFT ASTM 304L / EN 1.4307

-

1.Elena Rodriguez

★ ★ ★ ★ ★

"It has excellent corrosion resistance which has kept all my projects looking pristine, even in harsh coastal environments."

-

2.Marcus Johannsen

★ ★ ★ ★ ★

"Highly recommend it for any food-related applications."

-

3.Sofia Clarke

★ ★ ★ ★ ★

"ASTM 304L stainless steel has proven to be exceptionally resistant to saltwater corrosion, significantly extending the life of our products."

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel

AISI 444 Stainless Steel | EN 1.4521 Stainless Steel ASTM / AISI 321H / EN 1.4878

ASTM / AISI 321H / EN 1.4878 EN 1.4436 / ASTM 316 Stainless Steel

EN 1.4436 / ASTM 316 Stainless Steel ASTM 310S - EN 1.4845

ASTM 310S - EN 1.4845 ASTM 309S - EN 1.4833

ASTM 309S - EN 1.4833 ASTM 439 - EN 1.4510

ASTM 439 - EN 1.4510 ASTM 434 - EN 1.4113

ASTM 434 - EN 1.4113 ASTM 321 - EN 1.4541

ASTM 321 - EN 1.4541