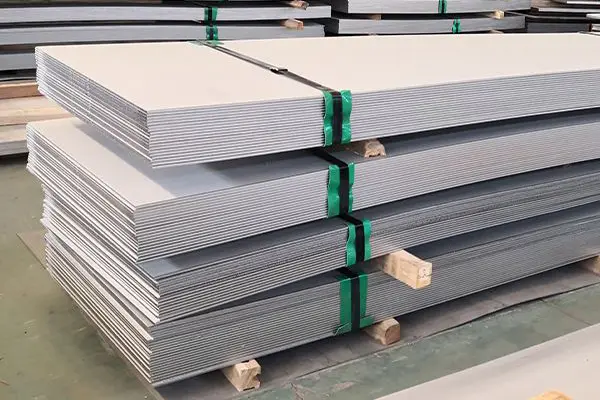

What are the common surface processes for stainless steel?

The common surface processes for stainless steel include cleaning, passivation, pickling, and polishing.

Here are the details:

Sandblasting is the removal of dirt and oxidised layers from the surface of stainless steel by blasting abrasive particles at high speed.

Electroplating is the deposition of metal ions on the surface of stainless steel to increase its corrosion resistance and decorative properties.

Anodising is to increase the corrosion resistance and hardness of stainless steel by forming an oxide layer on its surface.

Coating is the application of a protective coating to the surface of stainless steel to provide additional corrosion resistance and decorative properties.