This UNS N04401-compliant alloy is well-suited for specialized electrical and electronic applications. Autogenous gas tungsten arc welding is a reliable method for joining the material, and it also displays good brazing properties. Resistance welding is also suitable.

| Chemical Composition |

28~34Cu-2.5Fe-2Mn-63Ni |

| Physical Property |

• Density: 8.89 gm/cm³

• Tensile Strength: 480 MPa

• Yield Strength: 250 MPa

• Elongation at break: 30% |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

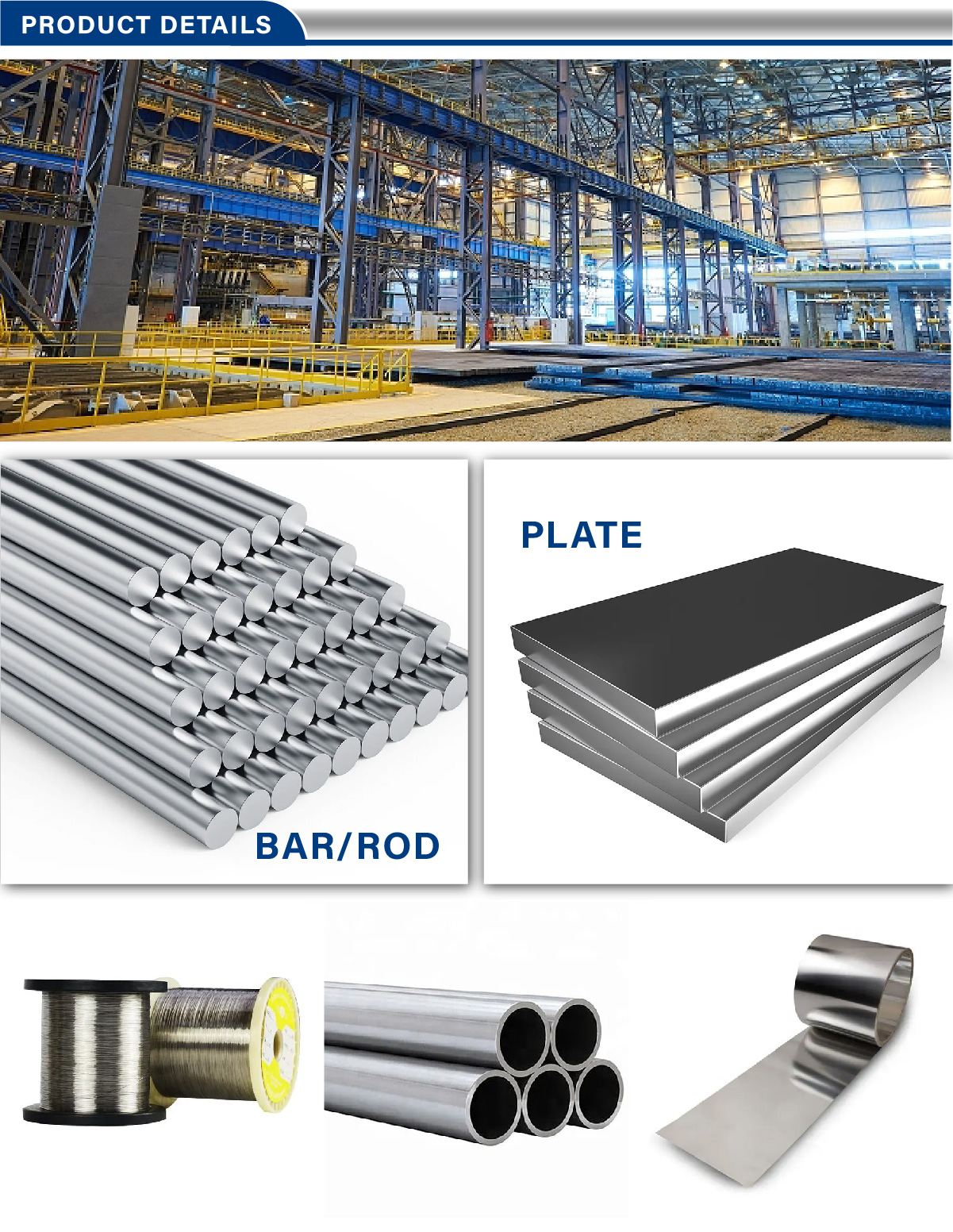

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

MONEL 401 is designed for use in special electric and electronic applications. It has a very low temperature coefficient of resistance and medium-range electrical resistivity. Used for wire-wound precision resistors and bi-metal contacts. Monel 401 is higher in copper content than Monel 400 for better electrical properties.

Applications:

- Wire wound resistors

- Bimetal contacts

- Electric and electronic applications

- Precision foils (Circuits & Heaters for Electrical Resistance)

- Bimetal contacts

- Wound wire resistors