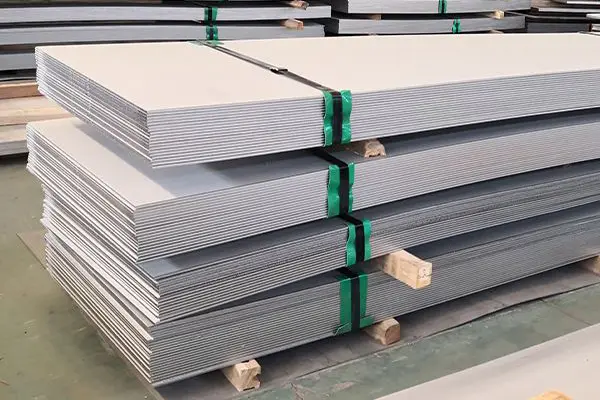

A stainless steel coil is a type of metal product made from stainless steel sheets or strips that have been wound or coiled after being rolled9. The following is a detailed introduction:

- Corrosion resistance:Stainless steel coils contain chromium and other elements. Chromium reacts with oxygen in the air to form a dense chromium oxide film on the surface, which can prevent oxygen, water, and other corrosive media from further eroding the metal, enabling the coil to be used for a long time without rusting in humid, acidic, alkaline, and other corrosive environments6.

- High strength:The strength of stainless steel coils is higher than that of ordinary steel. They have good compressive and tensile resistance, and can meet the requirements of various structural and engineering fields, providing reliable support and stability4.

- Good thermal conductivity:Stainless steel coils have excellent thermal conductivity, which allows them to transfer heat quickly and evenly. This property makes them suitable for applications where heat transfer is required, such as in heat exchangers2.

- High temperature and low temperature resistance:In high temperature environments, stainless steel coils have excellent oxidation resistance and can operate stably for a long time without failing due to surface oxidation. At low temperatures, they still maintain good toughness and mechanical properties, and will not become brittle or break easily6.

- Good plasticity and weldability:Due to the excellent design of the chemical composition and internal structure of stainless steel coils, they have good plasticity and can adapt to complex processing technologies such as cold stamping, bending, and stretching. At the same time, they also have good weldability and can be easily welded and processed to meet the manufacturing needs of different products6.

According to production process2

- Hot rolled stainless steel coil:It is made by hot rolling steel billets at high temperatures. Hot rolled coils have good formability and weldability, and are often used in applications where surface finish is not the most critical factor, such as in the construction of structural components.

- Cold rolled stainless steel coil:Cold rolled stainless steel coils are produced by further processing hot rolled coils through cold rolling. This process improves the surface finish, dimensional accuracy, and mechanical properties of the coil. Cold rolled coils are commonly used in applications where a smooth surface and high precision are required, such as in the manufacturing of household appliances and decorative materials.

- According to material composition

- Austenitic stainless steel coil:This is the most common type of stainless steel coil, characterized by good corrosion resistance, high ductility, and excellent formability. The most typical grades are 304 and 316. Grade 304 is widely used in various industries due to its good comprehensive performance, while grade 316 has better corrosion resistance in harsh environments, especially in the presence of chloride ions2.

- Ferritic stainless steel coil:Ferritic stainless steel coils contain a high proportion of ferrite phase. They have good corrosion resistance and heat resistance, and are often used in applications where moderate corrosion resistance and high-temperature resistance are required, such as in the automotive exhaust system 和 some architectural applications.

- Martensitic stainless steel coil:Martensitic stainless steel coils have high strength and hardness after heat treatment, but their corrosion resistance is relatively lower than austenitic and ferritic stainless steel. They are mainly used in applications where high strength and wear resistance are required, such as in the manufacturing of cutting tools and some mechanical parts.

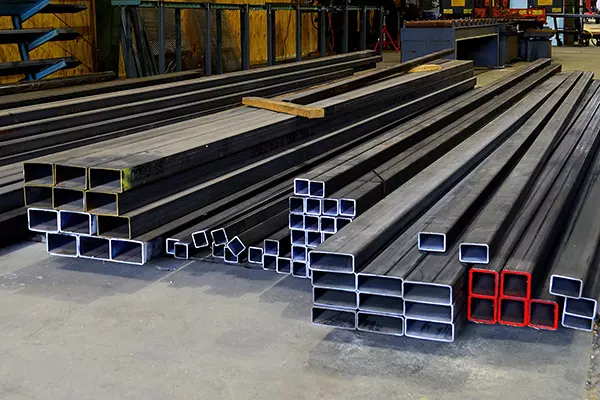

- Construction industry:Stainless steel coils are widely used in building facades, suspended ceilings, door and window decorations, handrails, and escalators. Their metallic luster and modern sense can enhance the fashion and quality of buildings, and can also maintain the flatness and beauty of the surface for a long time4.

- Kitchenware and appliance industry:In the kitchenware industry, stainless steel coils are used to make stoves, sinks, countertops, and other products. Their high temperature resistance, corrosion resistance, and easy cleaning properties make them the ideal material for kitchen utensils. In the appliance industry, they are used in the manufacturing of refrigerators, ovens, washing machines, and other household appliances4.

- Automotive industry:Stainless steel coils are used in the manufacture of automotive bodies, exhaust pipes, wheel covers, and other parts. The corrosion resistance and strength characteristics of stainless steel coils can effectively extend the service life of automobiles and improve the safety and reliability of the entire vehicle4.

- Chemical and pharmaceutical industry:In the chemical and pharmaceutical industries, stainless steel coils are used to make storage tanks, reactors, heat exchangers, pipelines, and other equipment. Their corrosion resistance and high temperature and pressure resistance can ensure the safety and stability of the chemical production process46.

- Medical device industry:Stainless steel coils are used in the production of surgical instruments, dental instruments, and other medical devices. Their hygienic properties, high durability, and easy cleaning characteristics make them the preferred material in the medical field4.

- Melting and casting:The production of stainless steel coils begins with the melting and casting of raw materials. Stainless steel scrap or high-purity iron raw materials are melted in a furnace and then cast into billets.

- Heating and rolling:The billets are heated in a heating furnace and then passed through a series of rolling mills to be deformed into plates or coils of the required size and thickness. This process usually includes high-temperature billet heating, pickling, cooling, finishing, and galvanizing.

- Cold rolling and reprocessing:The hot rolled stainless steel coils are further processed by cold rolling to obtain higher strength and toughness. In addition, surface treatment and dust prevention treatment are also carried out to improve the quality and service life of the coils.

- Edge processing and cutting:After cold rolling and other processes, the stainless steel coils need to be edge processed and cut to meet the specific requirements of different applications.