Incoloy MA956 is an iron-base alloy designed for demanding environments. Produced by mechanical alloying, the nominal composition includes 20% chromium, 15% aluminum, 0.5% titanium, and 0.5% yttrium oxide. This alloy displays enhanced oxidation and corrosion resistance, making it ideal for tough applications.

| Chemical Composition |

74Fe-20Cr-4.5Al-0.5Ti-0.5Y2O3 |

| Physical Property |

• Density: 7.25 g/cm³

• Melting Range: 1311-1400°C

• Tensile Strength: 650 MPa

• Yield Strength: 550 MPa

• Thermal conductivity: 10.9 W/mK

• Elongation: 9% |

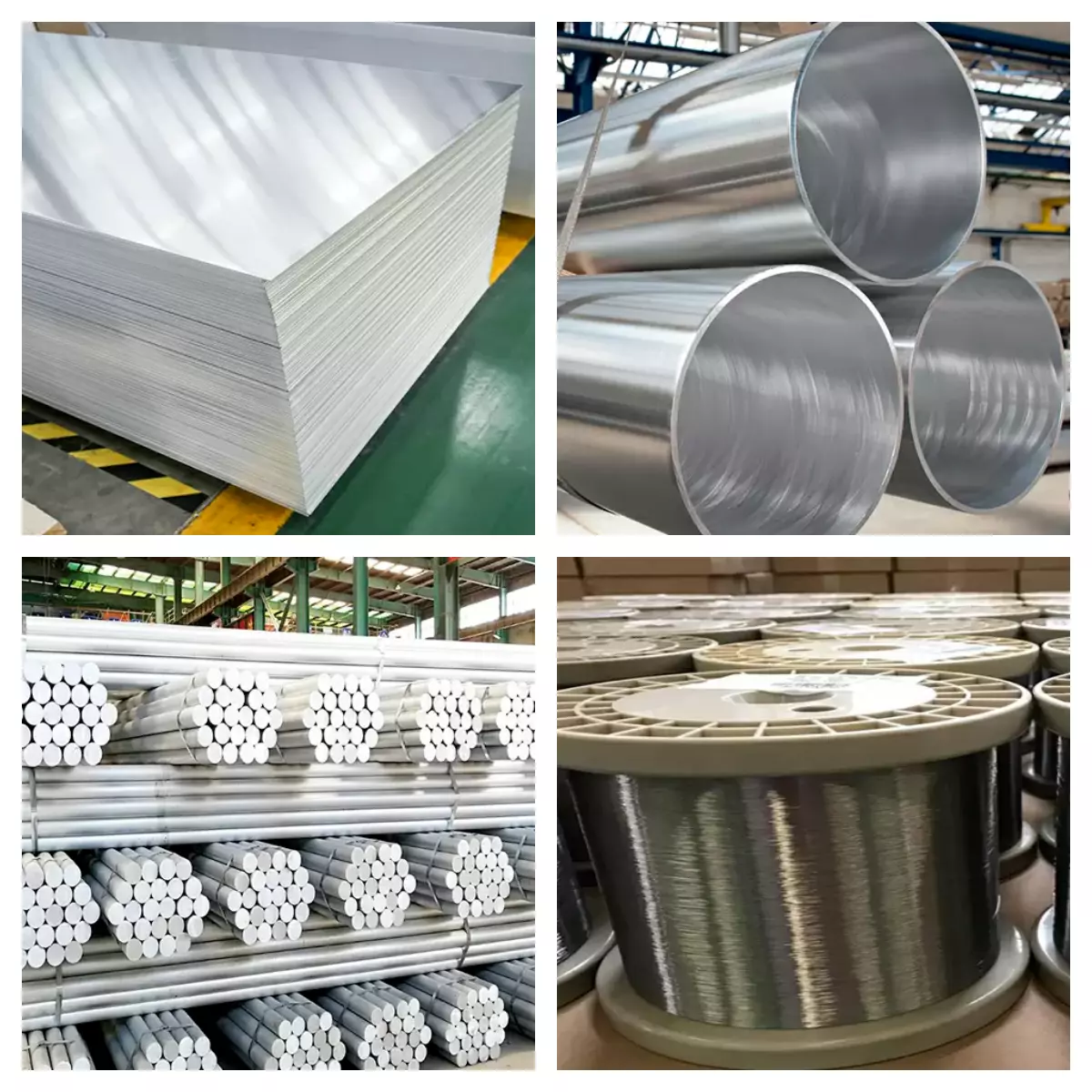

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

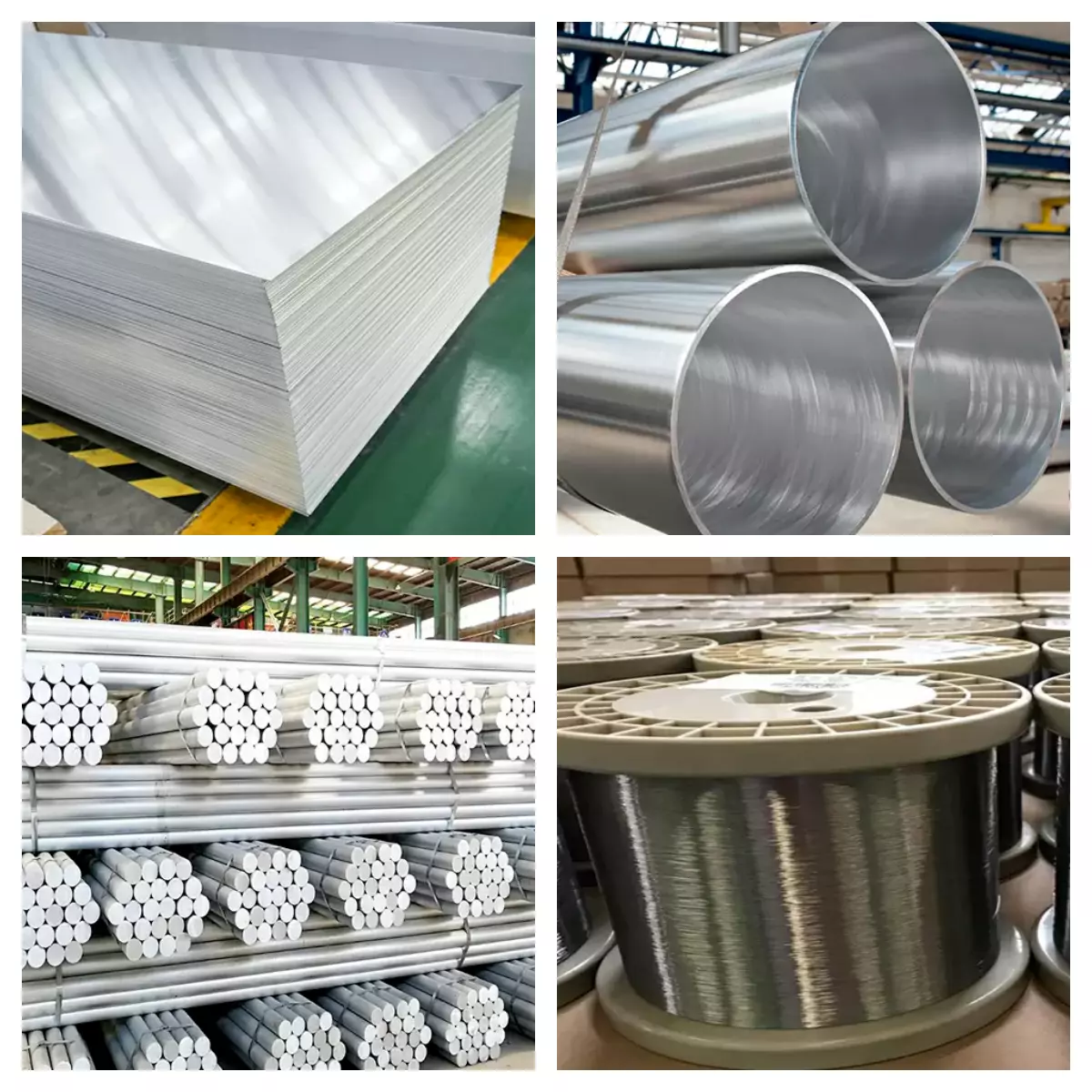

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

INCOLOY alloy MA956 is an aerospace superalloy that is now widely used for its superior strength and fabricability in industrial applications. Its unique composition ensures maximum resistance to temperatures up to 1300°C (2400°F), and its corrosion-resistant Fe-Cr-Al alloy is further reinforced with yttrium oxide particles for even better performance.

Applications:

- Gas-turbine combustion chambers

- Advanced energy-conversion systems

- Other applications that involves rigorous conditions