Incoloy 926 is an austenitic molybdenum stainless steel that displays superior corrosion resistance to numerous aggressive media. The mixture of molybdenum and nitrogen inhibits pitting and crevice corrosion, while copper boosts sulfuric acid tolerance and nitrogen increases yield and tensile strengths.

| Chemical Composition |

22.5Cr-46Ni-3.5Mo-0.5Nb-2.4Ti-3Cu-1Mn-0.35Si-0.5Al-0.02P-0.003S |

| Physical Property |

• Density: 8.1 g/cm³

• Tensile Strength: 600 MPa

• Yield Strength: 300 MPa

• Elongation at break: 40%

• Melting Point: 1320°C-1390 °C |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

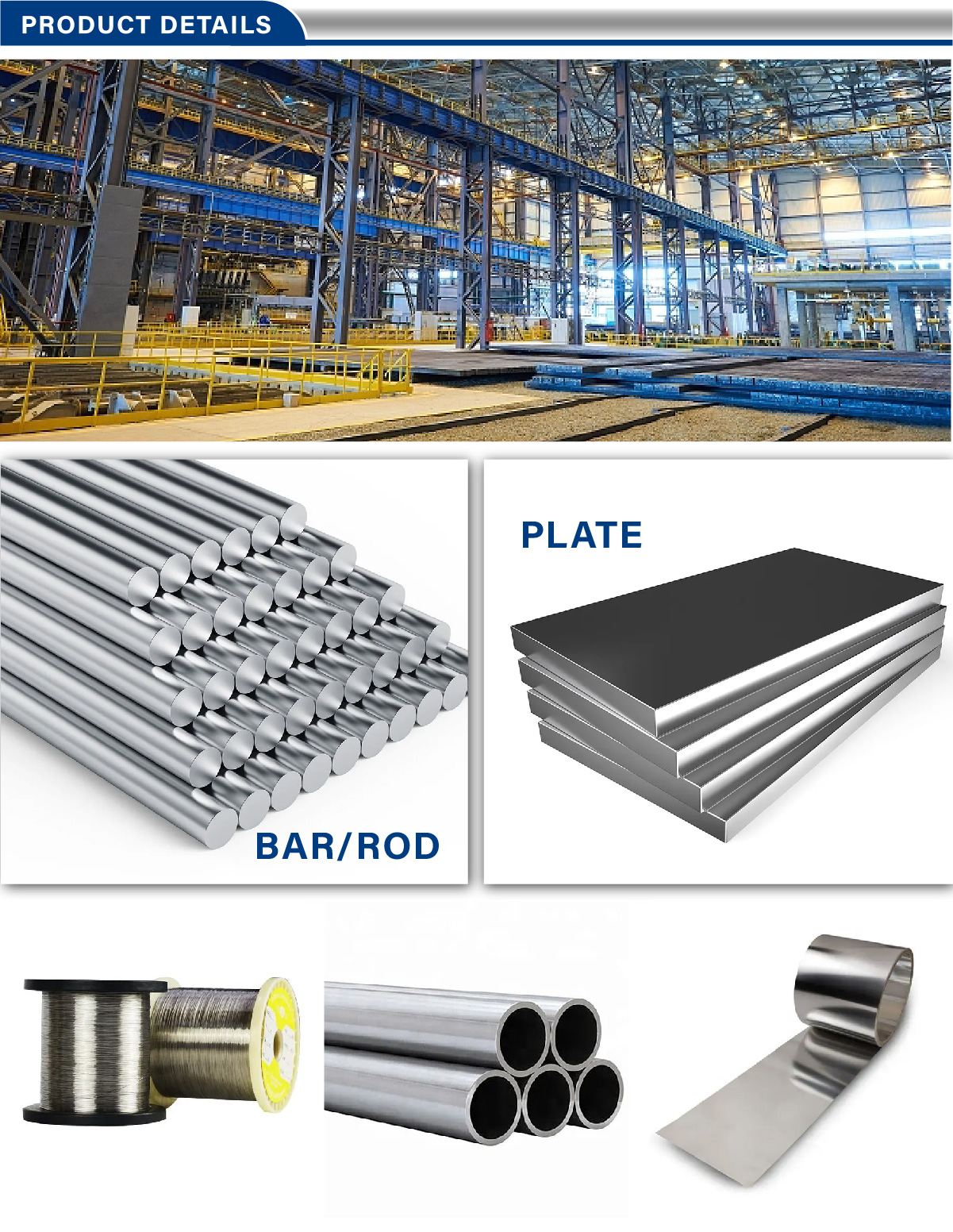

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Incoloy 926 (UNS N08926/W.Nr. 1.4529) is an austenitic stainless steel alloy which has a similar chemical composition with 904L alloy. Its nitrogen content is 0.2%, molybdenum content is 6.5%. Molybdenum and nitrogen content significantly increased the resistance of pitting and crevice corrosion in the halide media. Meantime, nickel and nitrogen not only ensures the stability of metallograghical, but also reduce separating intergranular trend in the thermal process or welding process better than the nitrogen content of nickel alloy.

Applications:

- Fire system, water purification system, marine engineering and hydraulic piping perfusion system.

- The pipeline, joint, air systems in the acidic gas production. Evaporator, the heat exchanger, filter, mixer, etc. in the phosphate production.

- Power plants condensation and pipe system in the use of sewage water to cool water.

- The use of acidic organic catalyst chlorinated derivatives production.

- The production of cellulose pulp,Polished bar in the orrosive oil wells.

- Hose system in the oceanngineering,Flue gas desulphurization system components.

- Sulfuric acid condensation and separation system,Crystalline salt concentration and the evaporator.

- Transport of corrosive chemicals containers,Reverse osmosis desalination plan.

- Heat exchange tubes

- Pipe fittings

- Flanges

- Valves