Incoloy 803 is a versatile austenitic stainless steel alloy with excellent corrosion resistance and high-temperature capabilities. It is able to resist oxidation, stress corrosion cracking, and pitting better than other materials, while offering superior quality at a cost-effective price point. Incoloy 803 is suitable for a variety of applications, from food processing to aerospace engineering.

| Chemical Composition |

29~42Fe-32~37Ni-25~29Cr-1.5Mn-1Si |

| Physical Property |

• Density: 7.86 g/cm³

• Tensile Strength: 552-621 MPa

• Yield Strength: 207-255 Mpa

• Modulus of Elasticity: 195 GPa

• Elongation: 40-45% |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

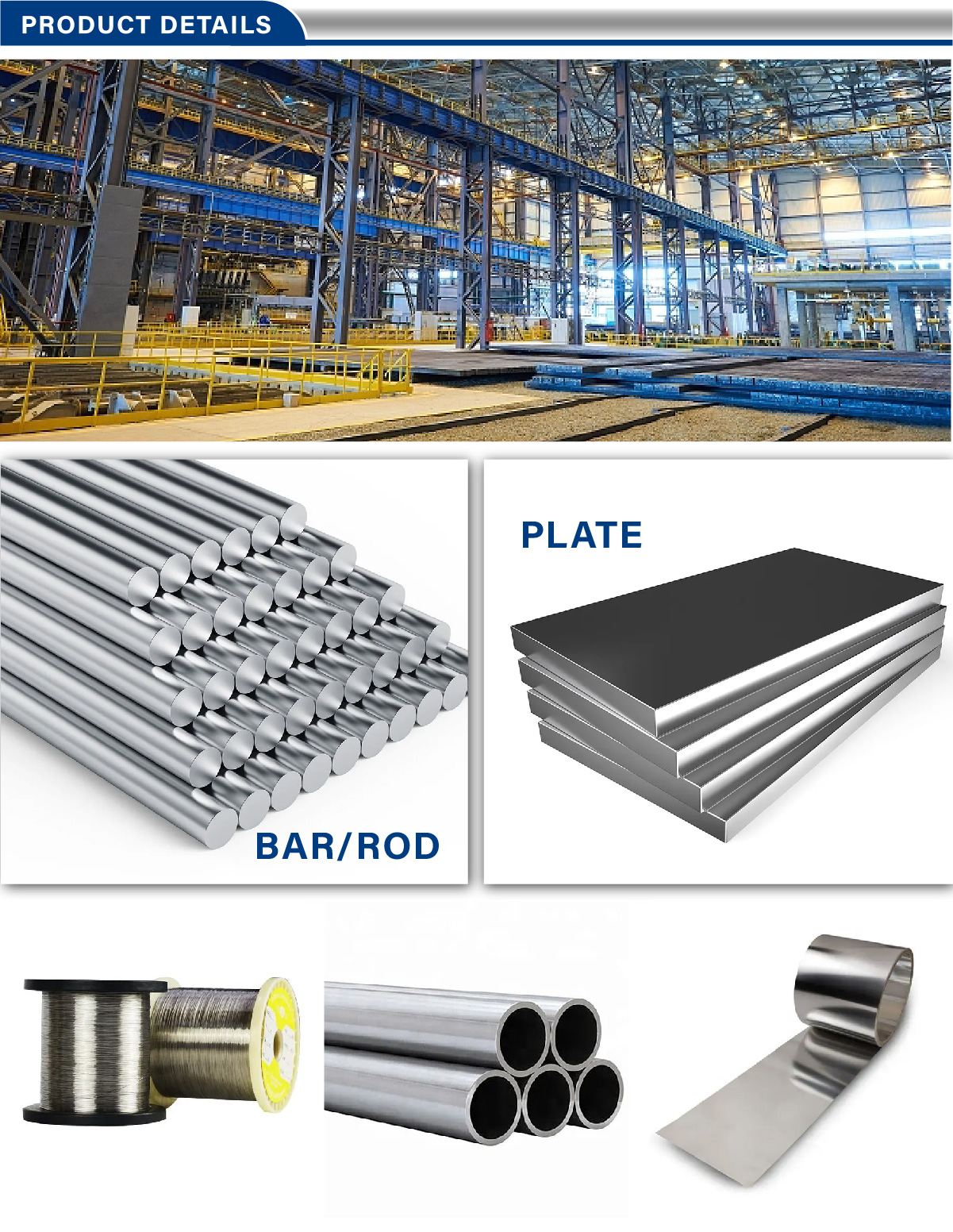

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

INCOLOY 803 is an iron-nickel-chromium alloy, offering corrosion resistance and superior stress-rupture strength in extreme temperatures. With a higher nickel and chromium content than other INCOLOY alloys, UNS S35045 offers cost-effective alternatives for replacing other metals in corrosive, oxidizing, and sulfidising environments. It is available in a variety of forms, including pipes, welds, tubes, plates, strips, rounds, squares, and forged fittings.

Applications:

- Petrochemical, chemical and thermal processes

- ID finned pyrolysis

- Tubing of high-severity ethylene furnaces