Inconel X-750 is a superalloy composed of nickel with additions of Ni3 (Al, Ti, Nb) that is heat-treated for strength and oxidation resistance up to 980℃, offering superior corrosion protection and superior tensile strength at temperatures up to 800℃.

| Chemical Composition |

70Ni-15Cr-6Fe-2.5Ti-0.6Al-1Nb-0.02C |

| Physical Property |

• Density: 8.28 g/cm³

• Tensile Strength: 1120 MPa

• Yield Strength: 850 MPa

• Elongation: 22%

• Reduction of Area: 30% |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

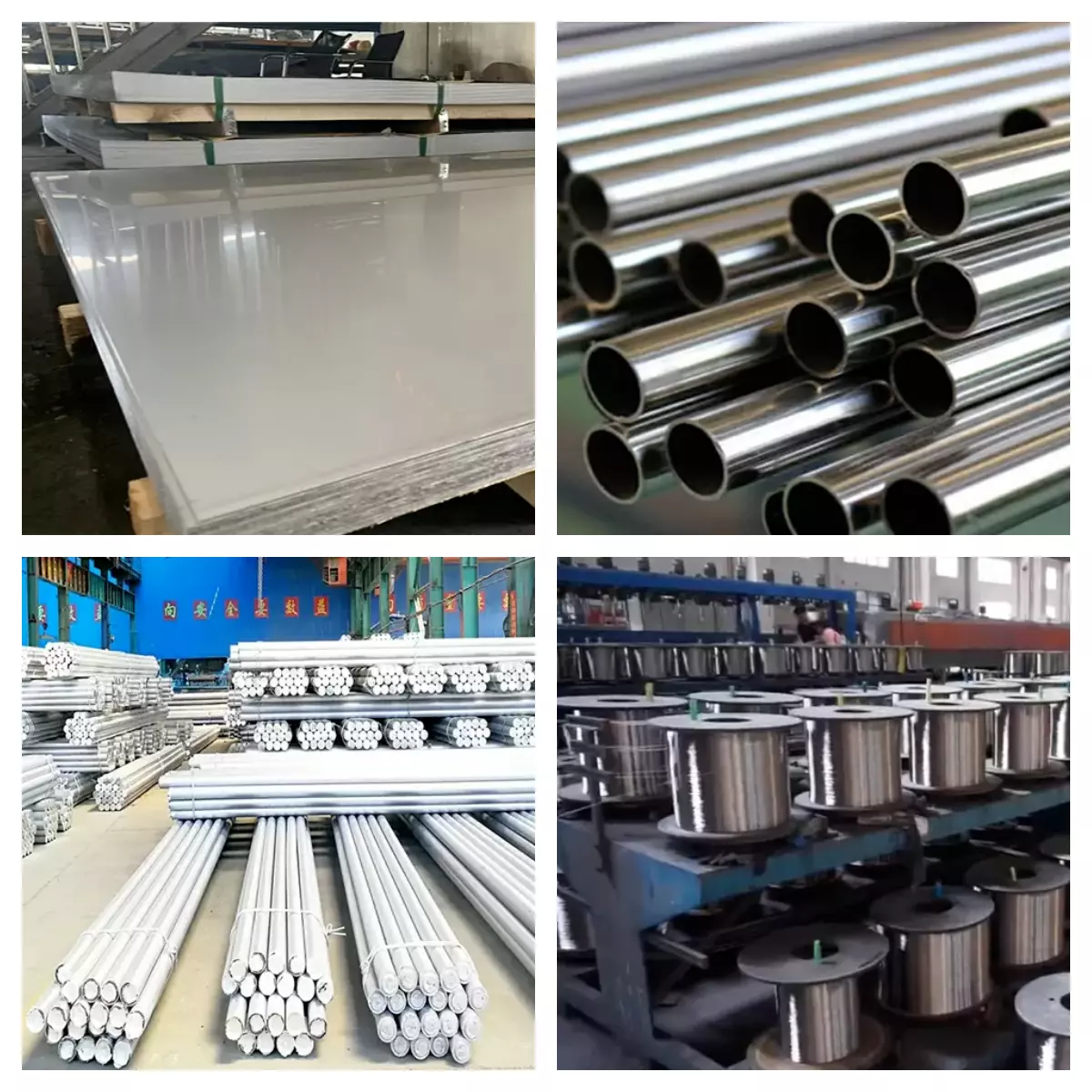

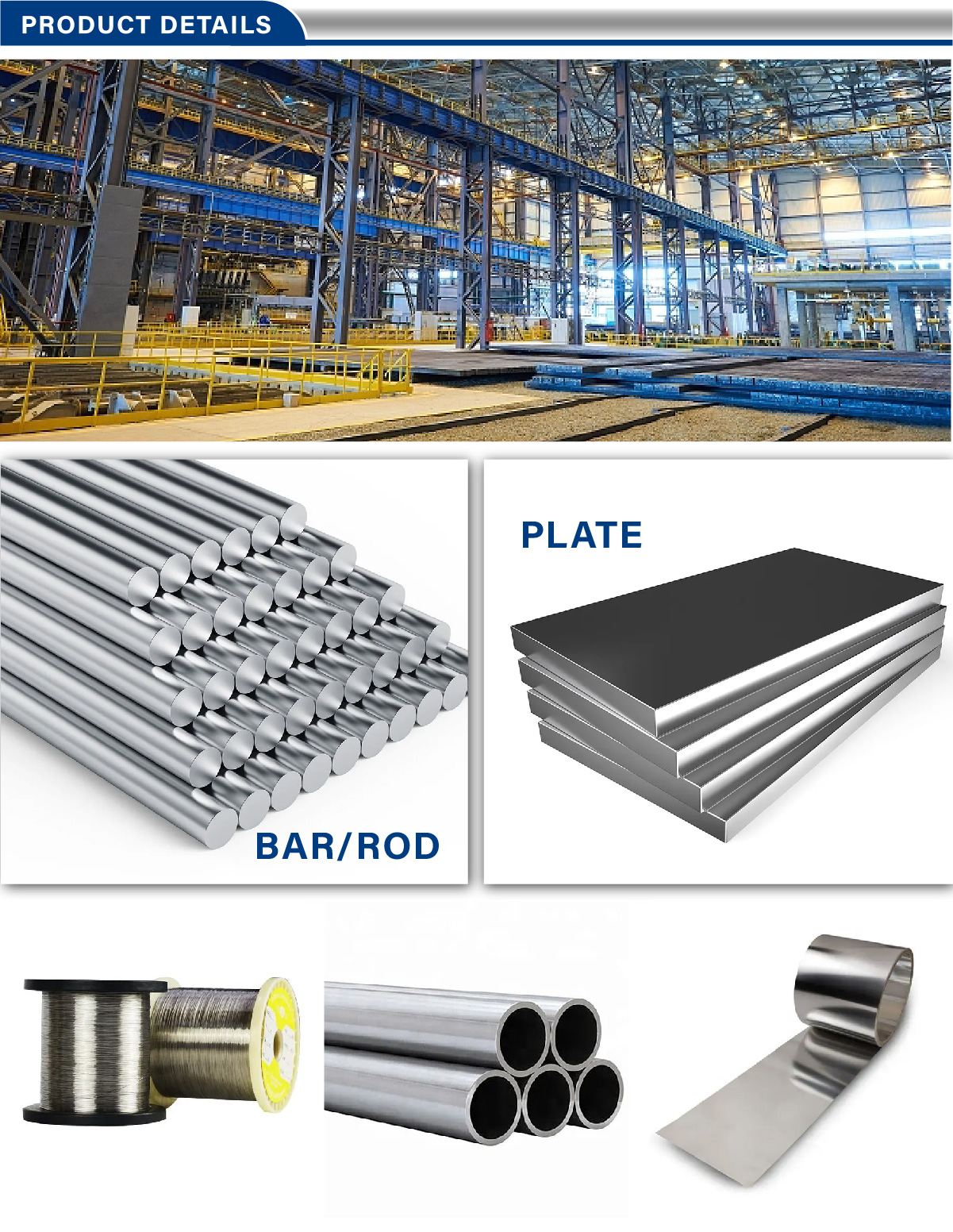

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Inconel alloy X-750 (UNS N07750/W. Nr. 2.4669) is a precipitation-hardenable nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300°F. Although much of the effect of precipitation hardening is lost with increasing temperature over 1300°F, heat-treated material has useful strength up to 1800°F. Alloy X-750 also has excellent properties down to cryogenic termperatures.

Application:

- Bellows

- Gas turbine

- Rotor blades

- Rocket engine chambers

- Springs

- Fasteners