Inconel 713C is a nickel-based cast superalloy with excellent creep strength, thermal fatigue performance, and oxidation resistance below 900°C. Its alloy composition is simple and has a low density, making it ideal for hot isostatic pressing and subsequent heat treatment, improving plasticity and fatigue properties while restoring the structure and performance of parts.

| Chemical Composition |

0.14C-9.5C-10.3Cr-2Co-5Ti-12Al-0.01W-0.048Zr-0.99Nb-Ni |

| Physical Property |

• Density: 7.91 g/cm³

• Thermal Conductivity: 20.9 W/m-K

• Tensile Strength: 110 psi

• Heating temperature: 1200℃ |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

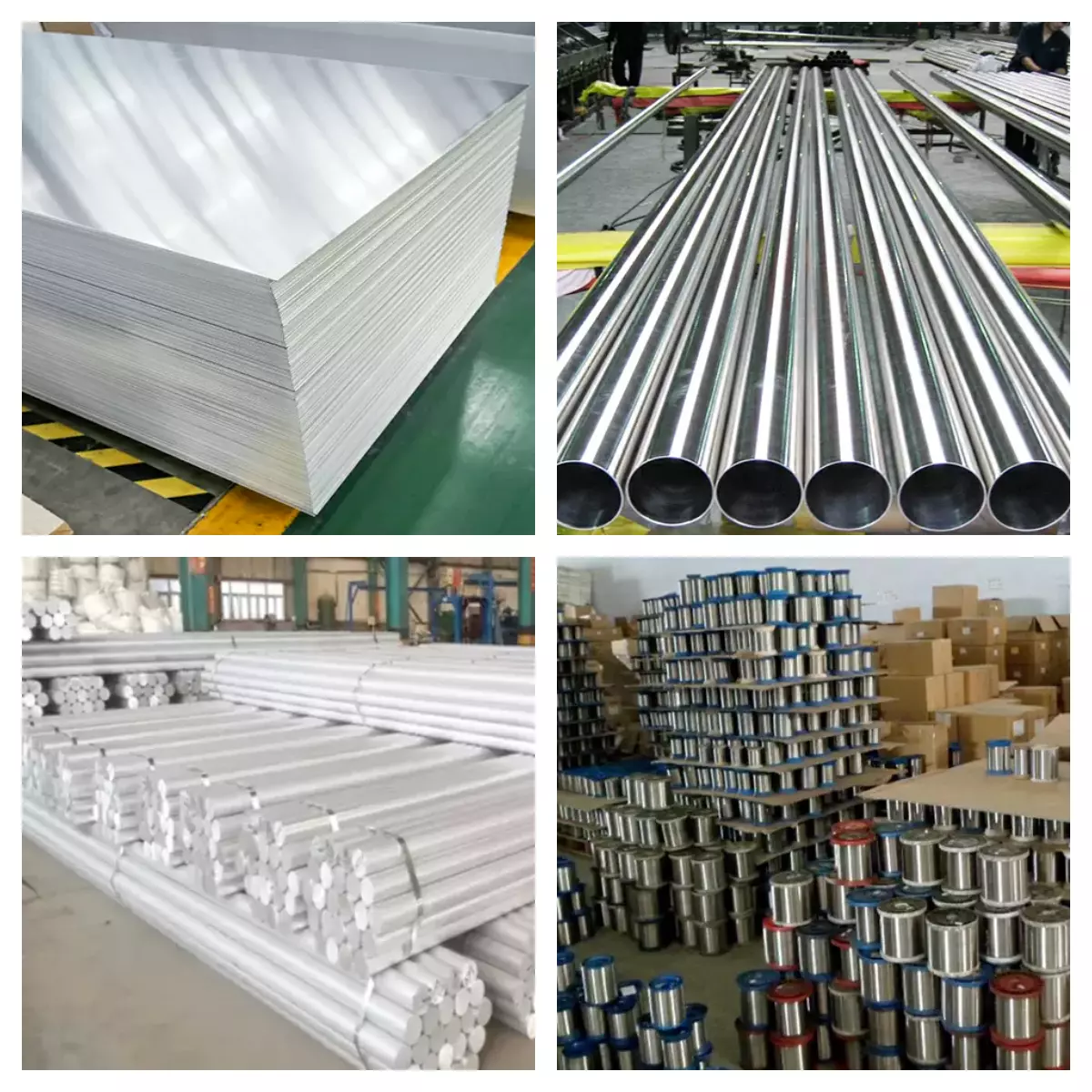

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

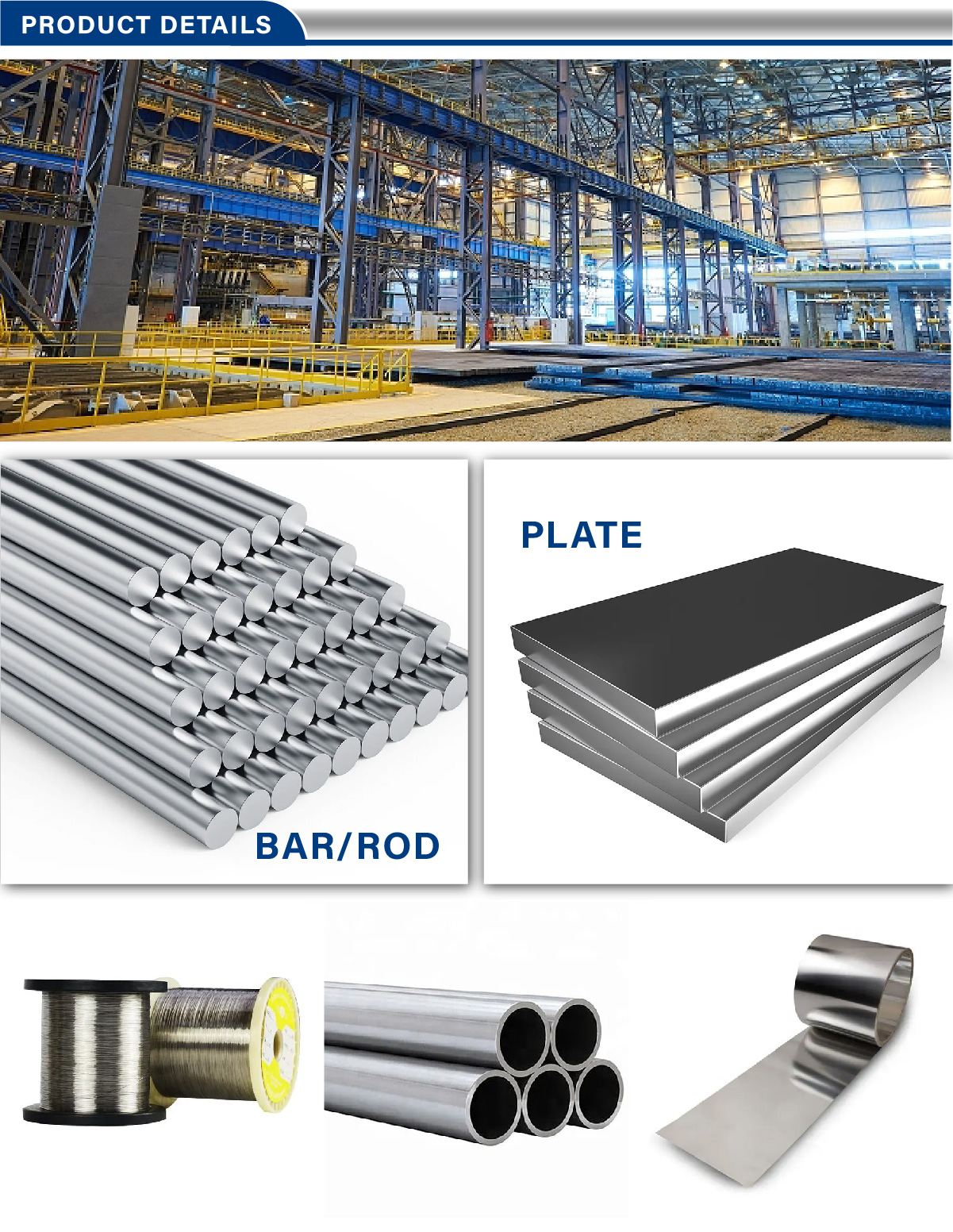

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Inconel 713C is a precipitation-hardening nickel-chromium base cast alloy with superior strength properties up to 1800ºF (980ºC). It offers good castability, excellent resistance to oxidation and thermal fatigue, and higher tensile strength than other similar alloys.

Applications:

- Automotive industry (turbochargers)

- Engine construction (compressors, impellers)

- Plant engineering (aggressive media)

- Racing (valves, manifolds)