Super Alloys Inconel 706 is a high-caliber nickel-chromium alloy with exceptional strength, resistance to high temperatures and corrosion resistance. It is useful in low-temperature applications and performs well in air up to 1300°F. This metal is malleable and can be hardened through aging.

| Chemical Composition |

0.03C-16Cr-42Ni-1.75Ti-40Fe-2.9Nb |

| Physical Property |

• Density: 8.05 g/cm³

• Tensile Strength: 757 MPa

• Yield Strength: 383 MPa

• Melting Point: 1360°C

• Modulus of Elasticity: 210 GPa |

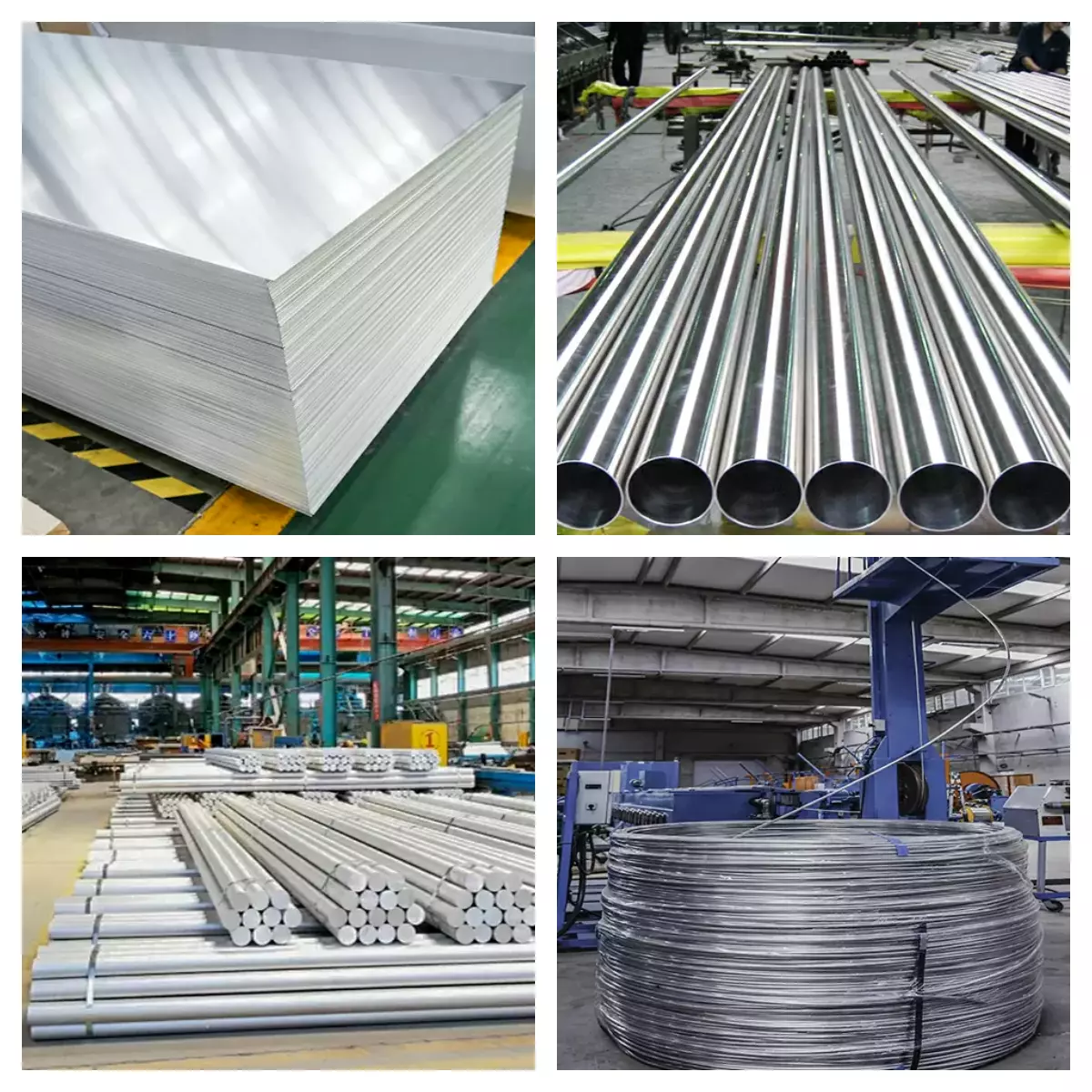

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

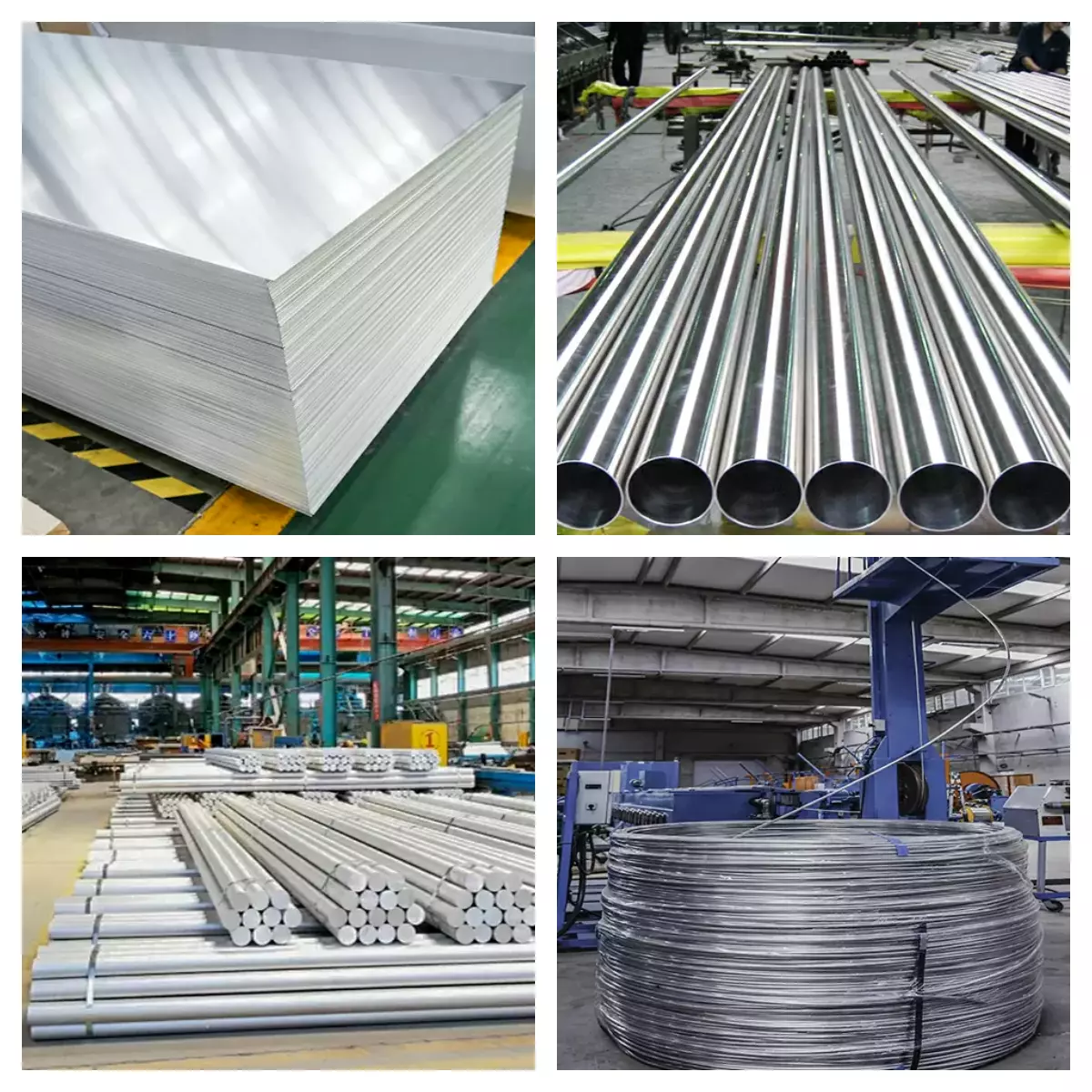

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

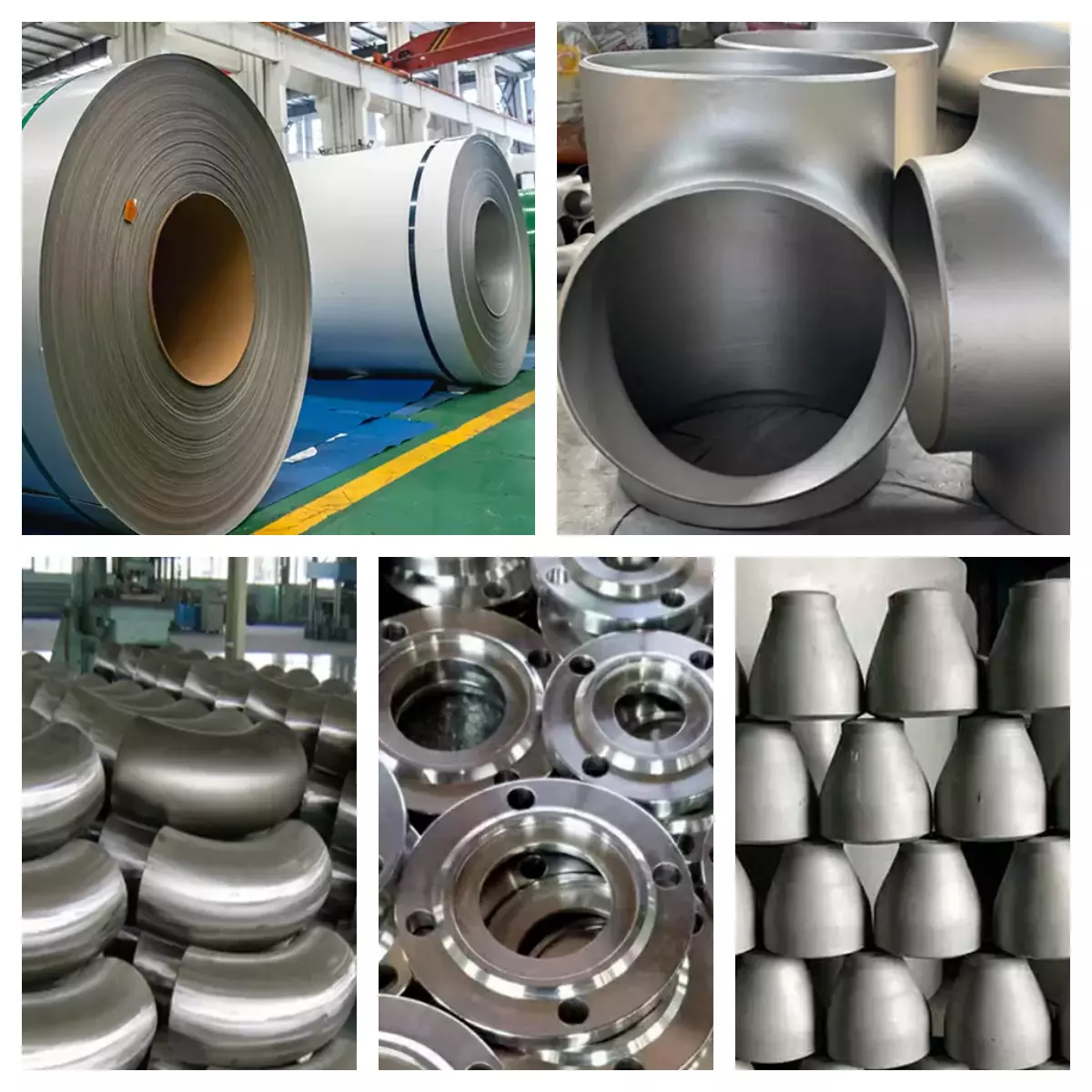

| Product Forms |

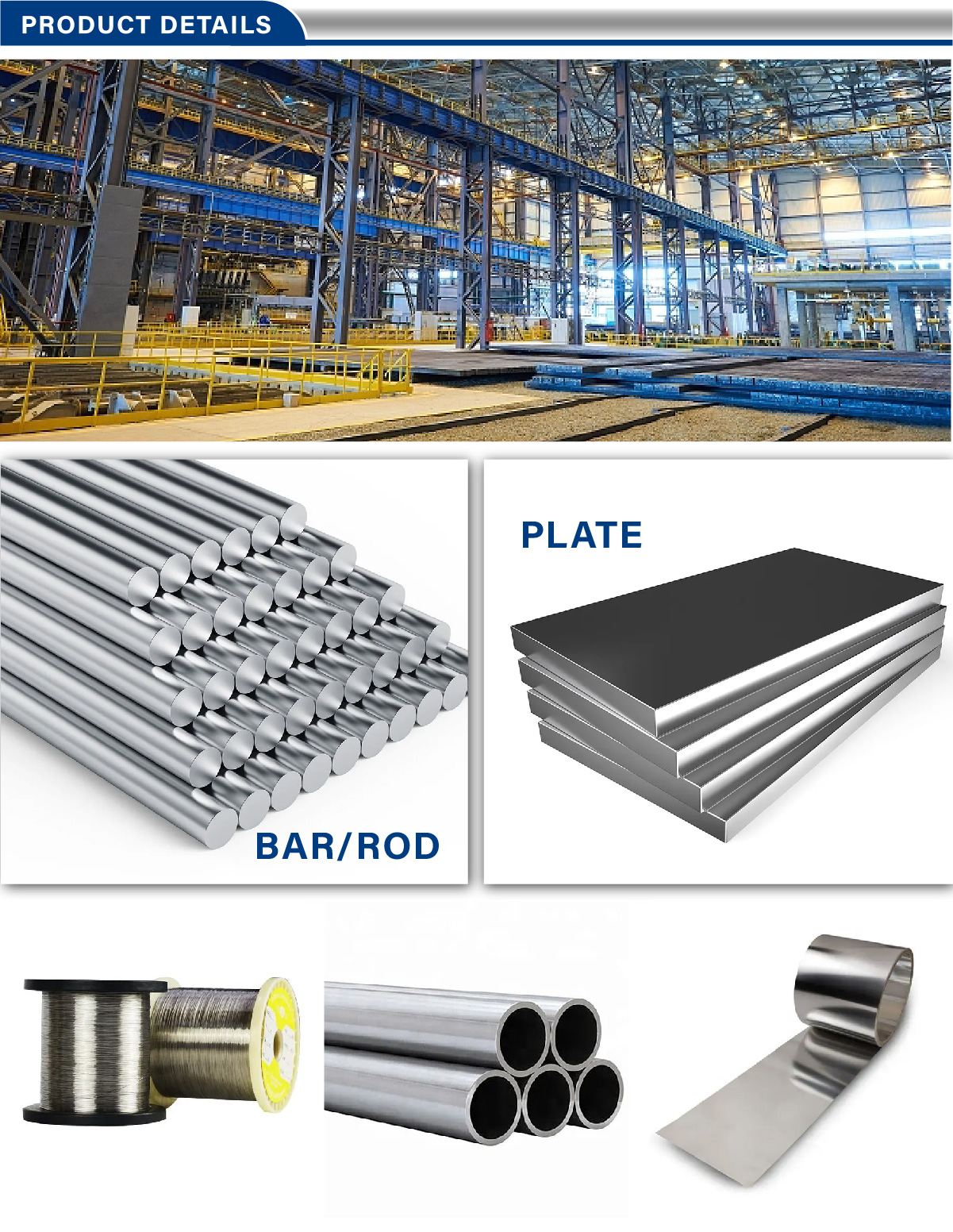

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

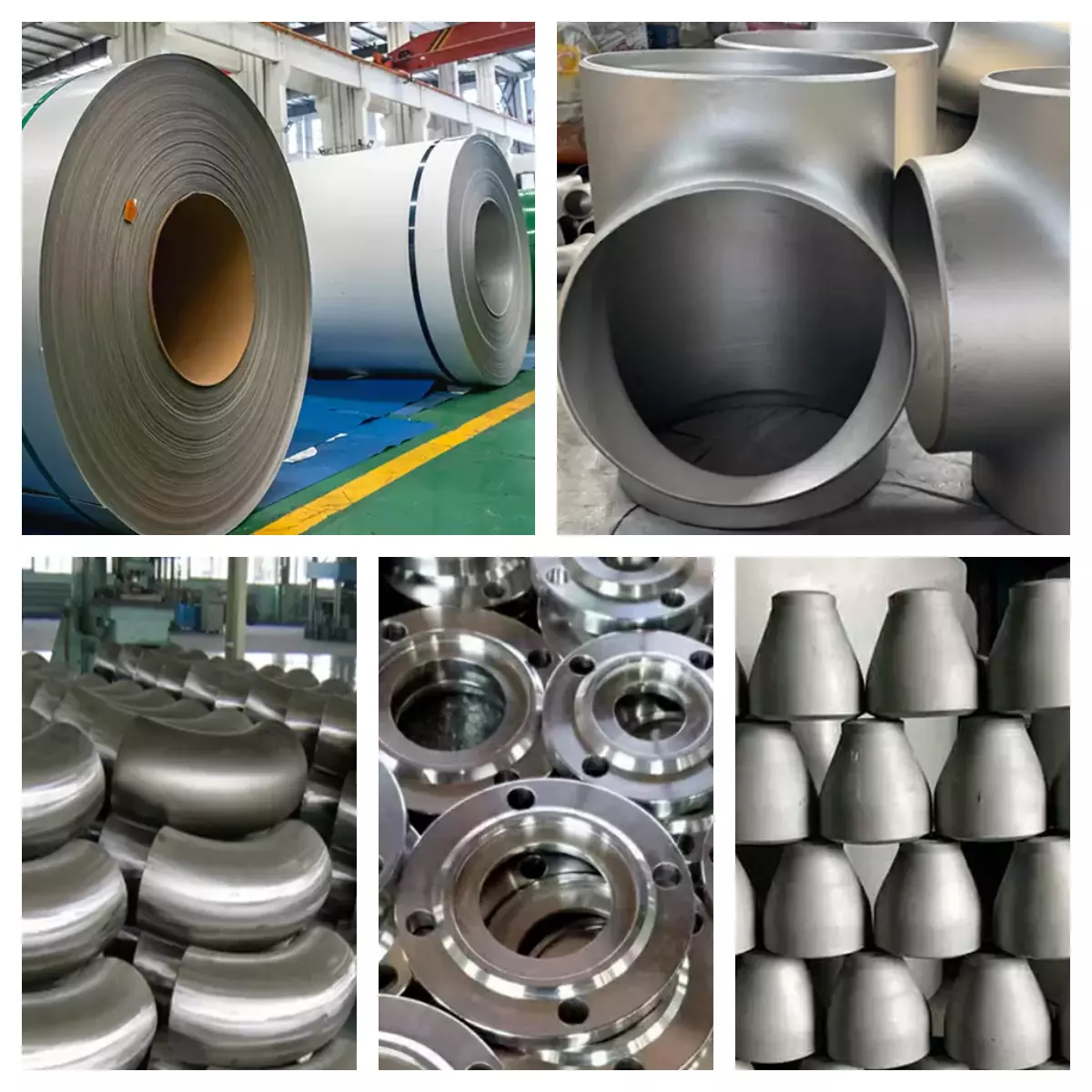

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Super Alloys Inconel 706 is a high-strength, high-temperature resistant and corrosion resistant nickel-chromium alloy. It is suitable for use at cryogenic temperatures and also for use in air up to 1300 F. The alloy is readily worked and can be age-hardened.

Applications:

Inconel 706™ is mainly used in gas turbines for shafts, cases, turbine discs, and fasteners.