Inconel 702 combines nickel, chromium, and aluminum to provide resistance to oxidation at up to 2400°F, with good strength at elevated temperatures. Heat treatment yields up to 1500°F, increasing its strength even further. Common applications include furnace components and afterburner liners.

| Chemical Composition |

3.25Al-15.5Cr-1Fe-79.5Ni-0.63Ti |

| Physical Property |

• Density: 8.43 g/cm³

• Tensile Strength: 130 ksi

• Yield Strength: 95 ksi

• Melting Range: 2540 °F

• Hardness: 25 |

| Stock & Dimensions |

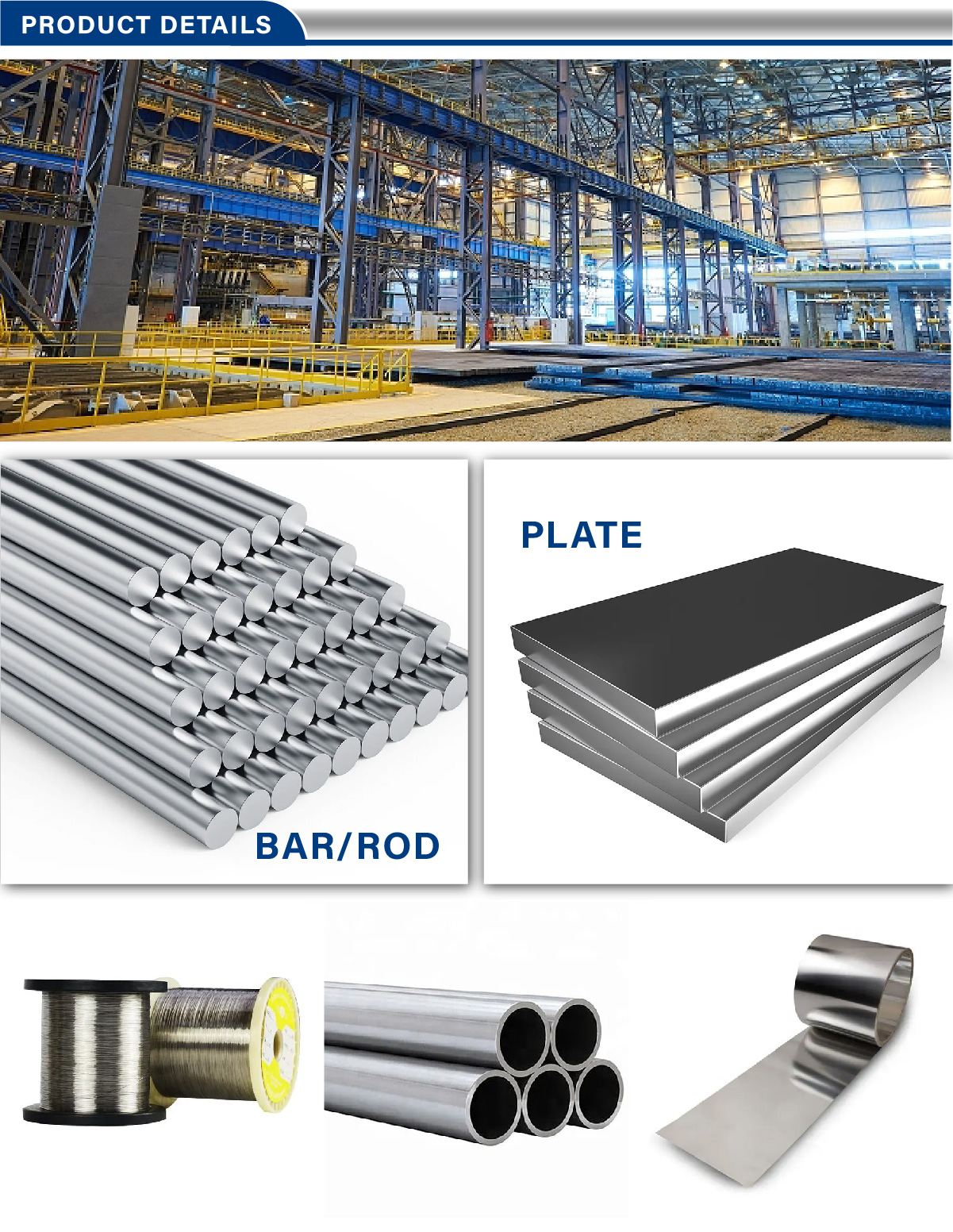

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Inconel 702 is a nickel-chromium alloy with an addition of aluminum that makes this grade to produce high resistant to oxidation at temperatures up to 2400 °F. At high temperatures the alloy has good strength. Up to 1500 °F age hardening improves the strength.

Alloy 720 is useful in furnace components and afterburner liners. Inconel 720 can be hardened through heat treatment and cold working.

Applications:

Inconel 702™ is mainly used in jet engine heat exchangers.