Inconel 693

INCONEL 693 is resistant to high temperature corrosion as well as metal dusting in chemical and petrochemical settings. Furthermore, its high chromium content renders it particularly effective against oxidation and sulfidation.

INCONEL 693 is resistant to high temperature corrosion as well as metal dusting in chemical and petrochemical settings. Furthermore, its high chromium content renders it particularly effective against oxidation and sulfidation.

INCONEL 693 is resistant to high temperature corrosion as well as metal dusting in chemical and petrochemical settings. Furthermore, its high chromium content renders it particularly effective against oxidation and sulfidation.

| Chemical Composition | 0.15C-0.5Si-1Mn-27~31Cr-2.5~4Al-0.5Cu-1Ti-538~6Fe-53~67Ni |

| Physical Property | • Density: 7.77 g/cm³

• Melting point: 1317 - 1367 °C |

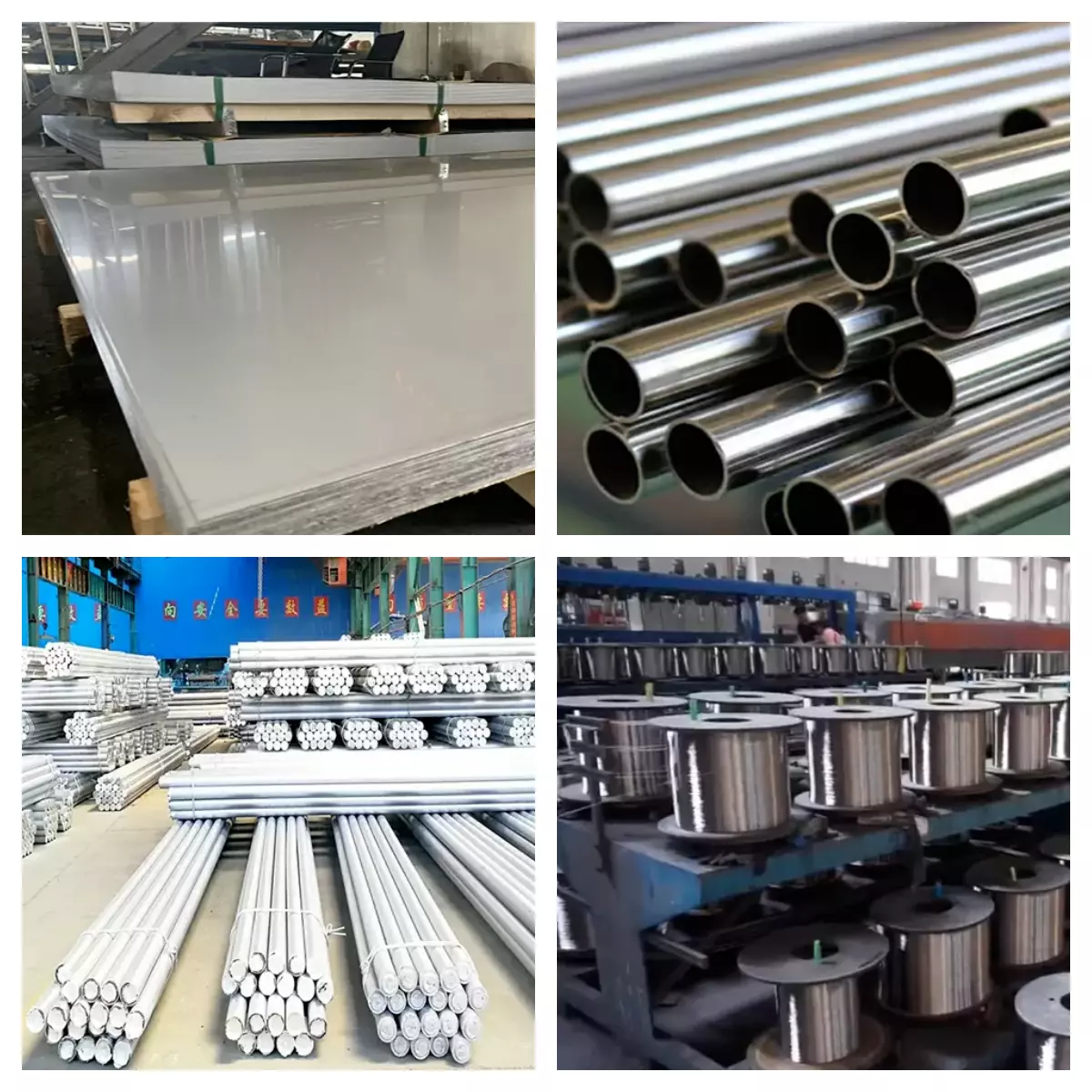

| Stock & Dimensions | Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs. • Bar: 0.5~600mm Diameter • Coil: 0.5~150mm Thick • Plate: 0.5~200mm Thick • Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick • Available in specific sizes |

| Product Forms | We provide you with a variety of product forms, including but not limited to: • Bar/Rod • Pipe/Tube • Coil/Strip • Plate/Sheet/Circle • Wire • Fitting (Flange, Elbow, Tee...) • Customize |

Essential details

Alloy 617 is a solid-solution, nickel-chromium-cobalt-molydenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environment, and it is readily formed and welded by conventional techniques.

The high nickel and chromium contents make the alloy resistant to a variety of both reducing and oxidizing media. The aluminum, in conjunction with the chromium, provides oxidation resistance at high temperatures. Solid-solution strengthening is imparted by the cobalt and molydenum.

Applications:

- Industrial furnace components

- Gas turbines

- Catalyst grid supports for nitric acid production

- Nuclear and fossil fuel productions