Inconel 690 features a high chromium content for exceptional resistance to oxidizing acids and certain salts, as well as some resistance to sulphidation at elevated temperatures. This alloy is specially suited for use in pickle shop duties when exposed to mixtures of nitric and hydrofluoric acids.

| Chemical Composition |

58Ni-30Cr-9Fe-0.2Cu-0.02C |

| Physical Property |

• Density: 8.19 g/cc

• Tensile Strength: 700 MPa

• Yield Strength: 379 MPa

• Elongation at Break: 46 %

• Modulus of Elasticity: 211 GPa

• Specific Heat Capacity: 0.450 J/g-°C |

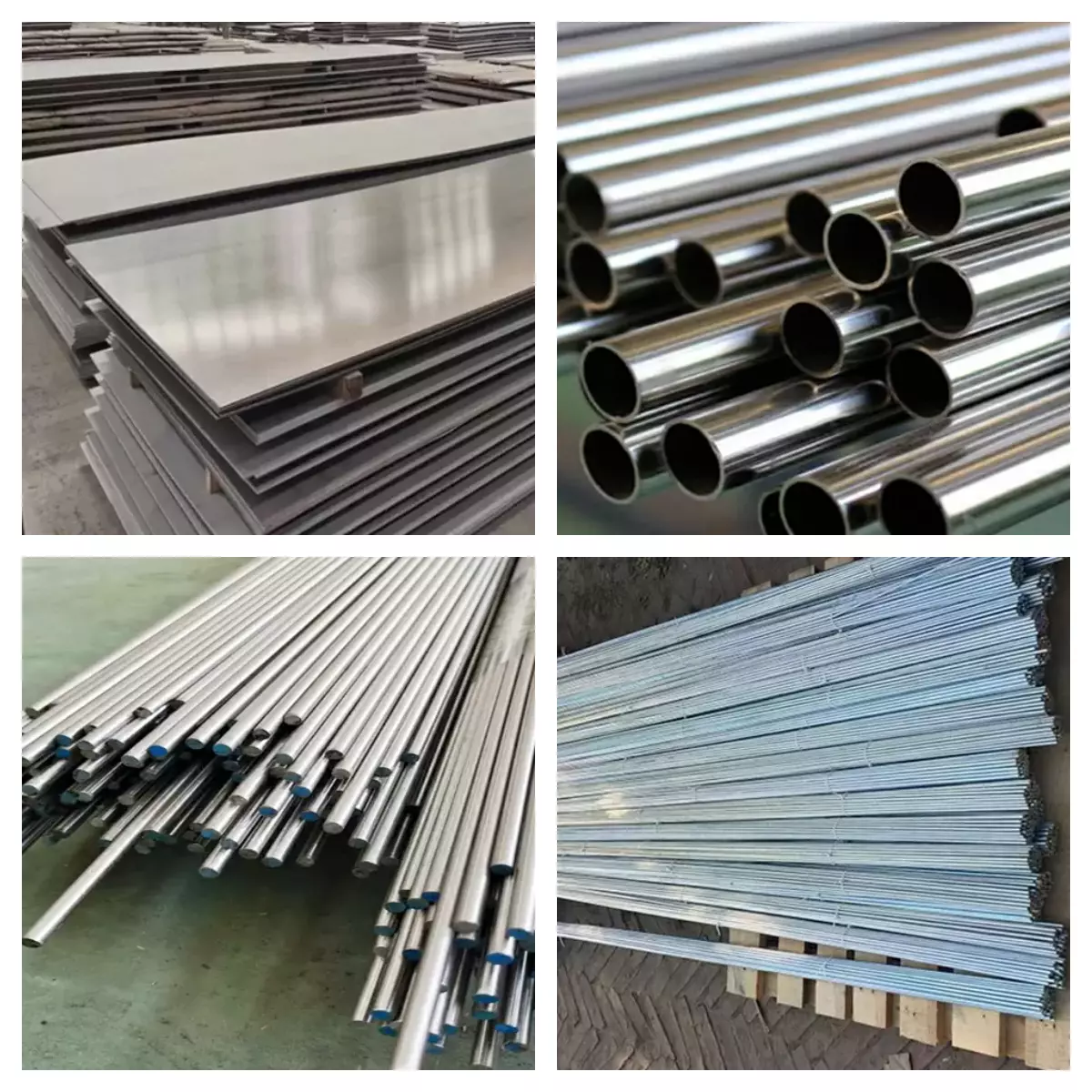

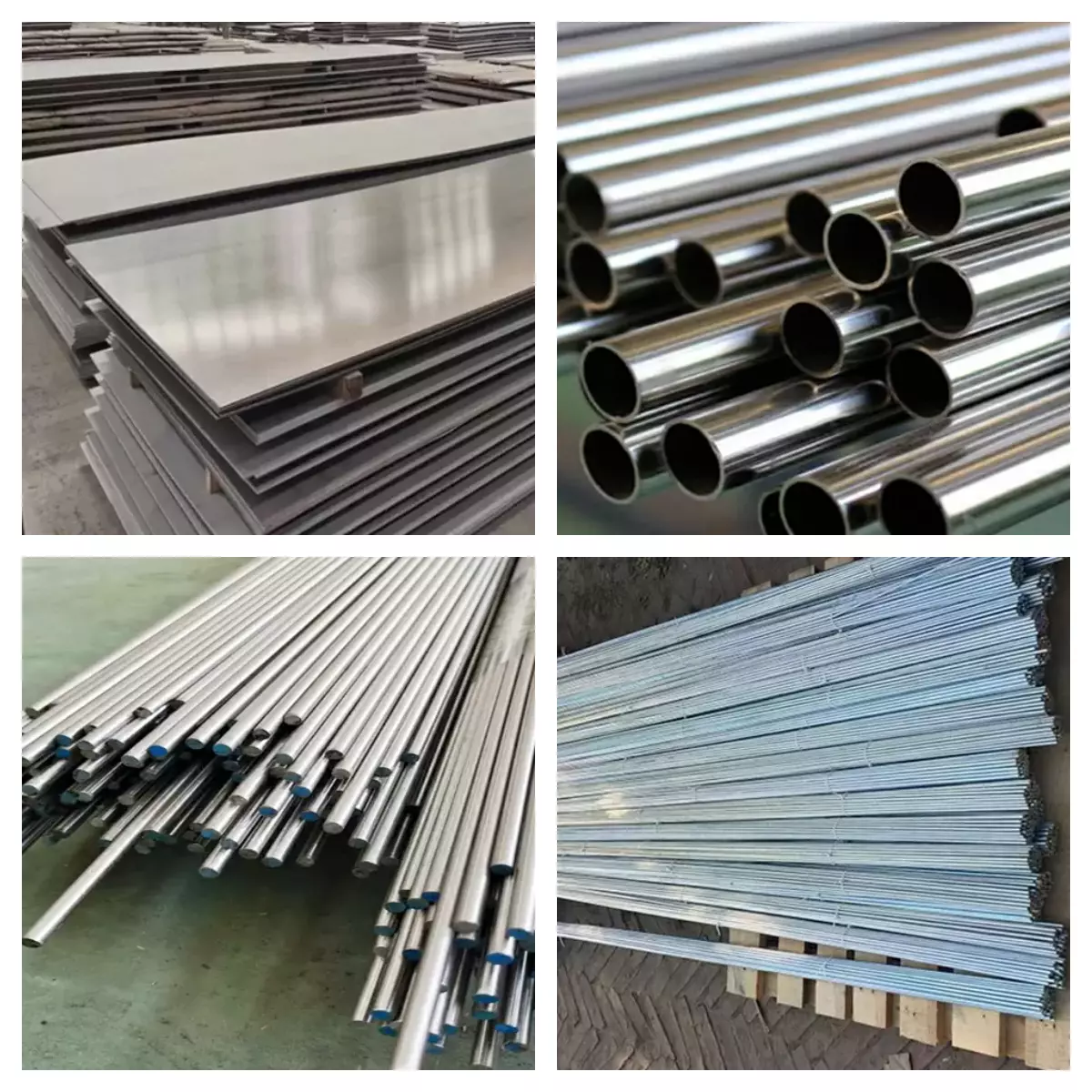

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

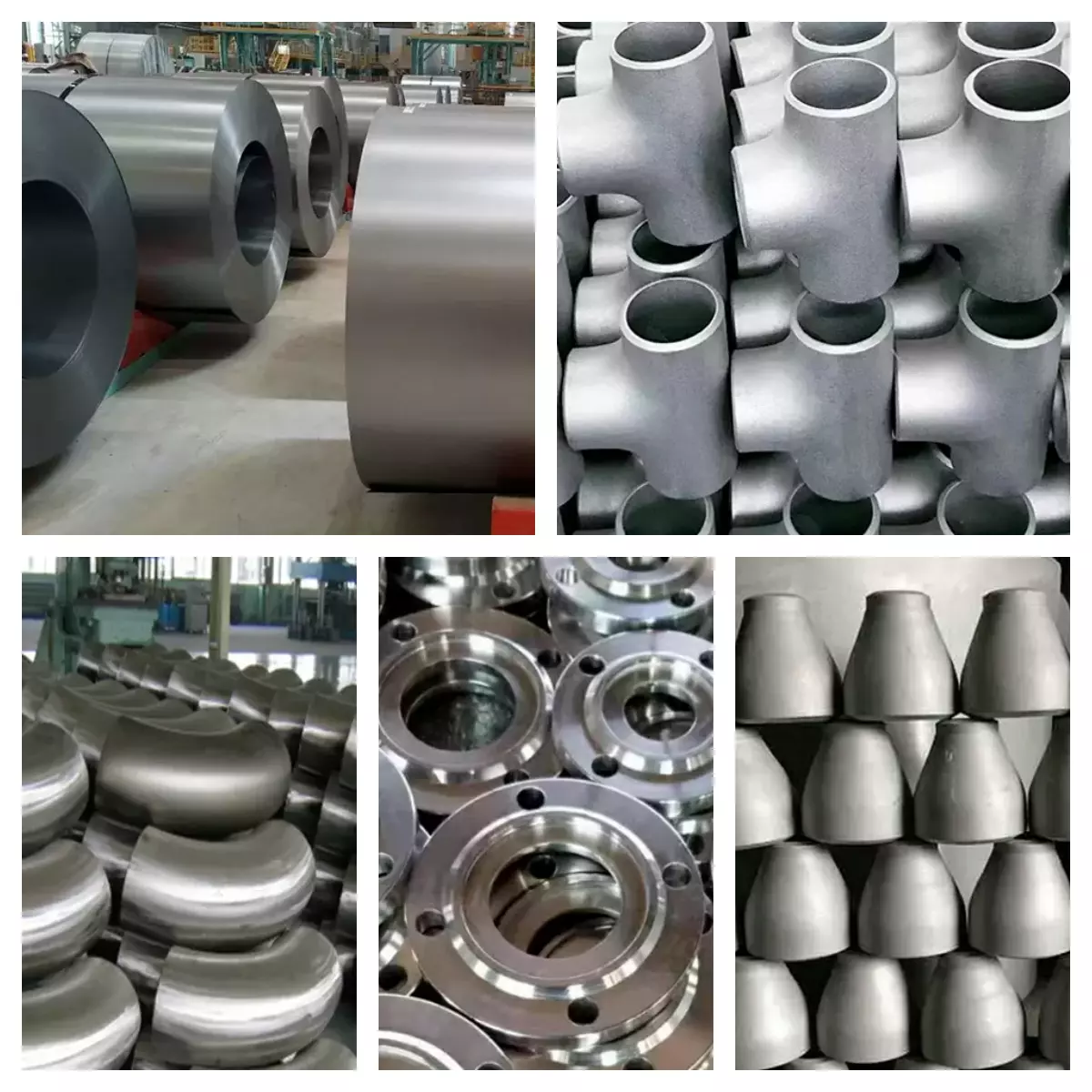

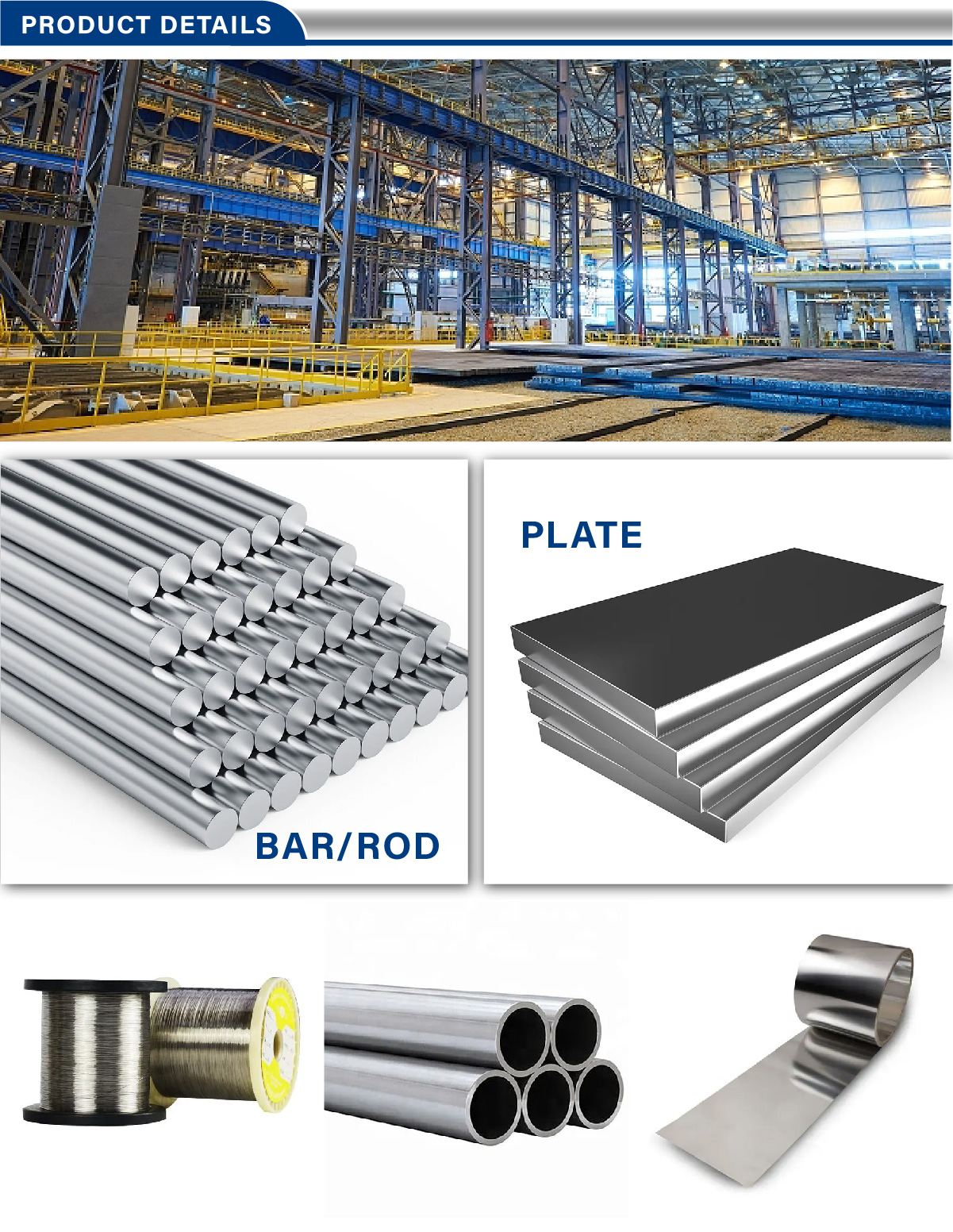

| Product Forms |

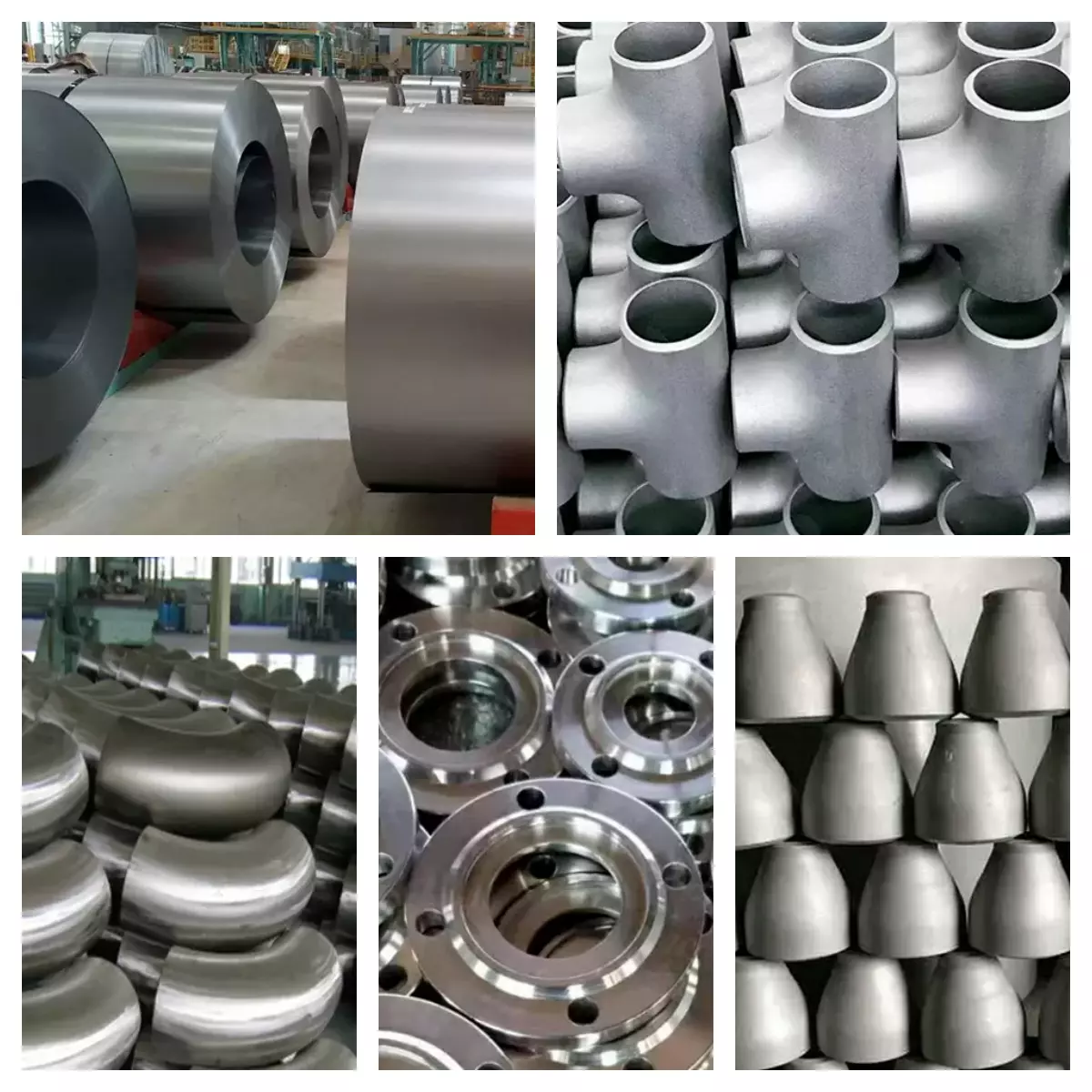

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

INCONEL Alloy 690 (UNS N06690/W. Nr. 2.4642) is a high-chromium nickel alloy having excellent resistance to many corrosive aqueous media and hightemperature atmospheres. In addition to its corrosion resistance, alloy 690 has high strength, good metallurgical stability, and favorable fabrication characteristics.

INCONEL alloy 690 is available in a wide range of standard mill forms including rod, bar, wire, pipe, tube, plate, sheet, strip and forging stock.

The superior stress cracking resistance of alloy 690 has caused it to supercede INCONEL® alloy 600 in steam generation nuclear reactors for piping, separators and weldments.

Applications:

- Heat exchangers

- Steam Generators

- High temperature applications exposed to caustic solutions