Inconel 686 is a nickel-based superalloy containing molybdenum and niobium for strength. It exhibits excellent resistance to corrosion and oxidation, with remarkable tensile strength up to 980 ℃. This alloy also offers good fatigue performance and stress corrosion resistance in salt spray environments.

| Chemical Composition |

57Ni-21Cr-16Mo-4W-0.01C |

| Physical Property |

• Density: 8.73 g/cc

• Tensile Strength: 722 MPa

• Yield Strength: 364 MPa

• Thermal Conductivity: 7.4 W/M-°C

• Modulus of Elasticity: 168 GPa

• Specific Heat Capacity: 0.364 J/g-°C |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

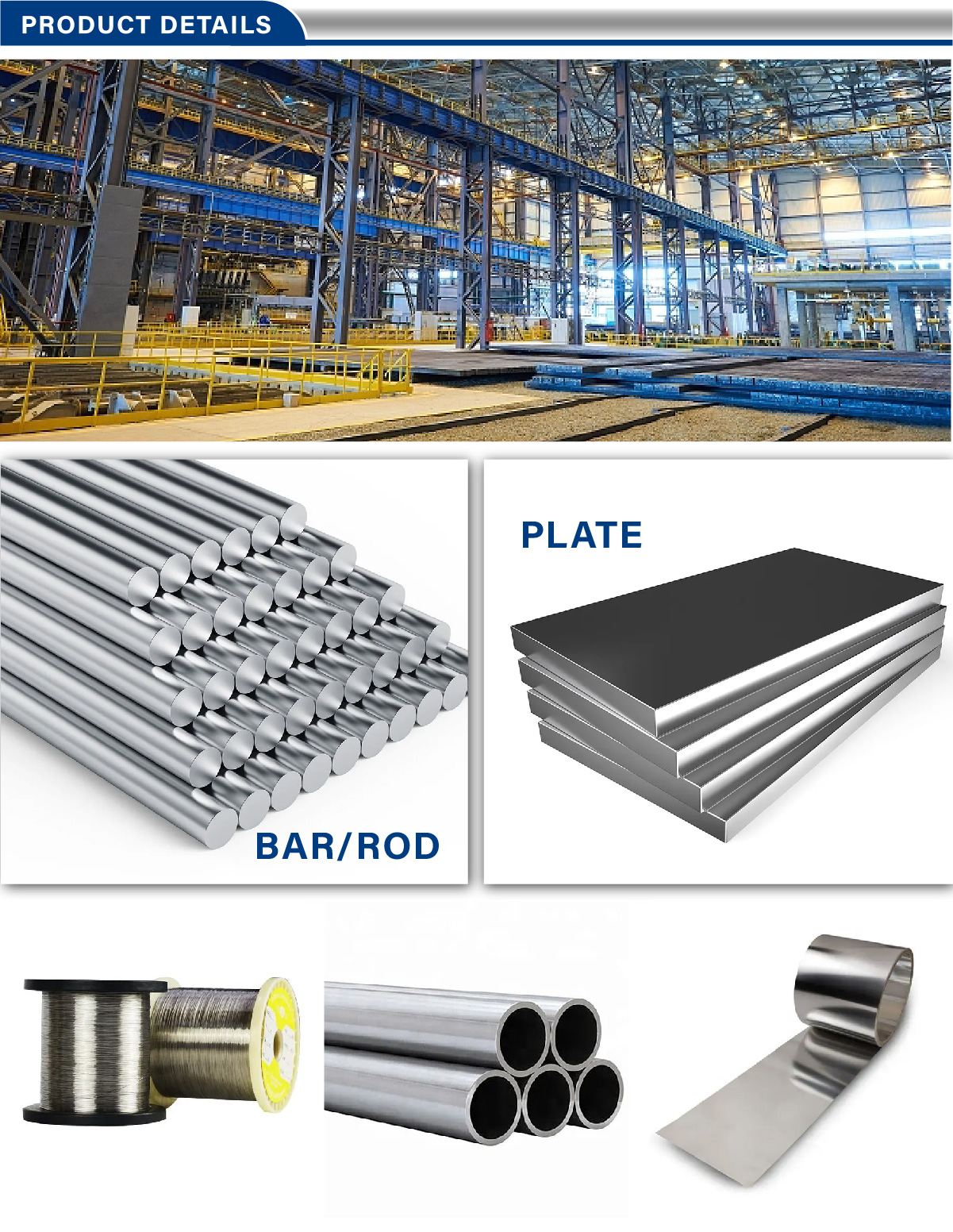

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

It is a solution strengthened nickel base deformed superalloy with molybdenum and niobium as the main strengthening elements, It has excellent corrosion resistance and oxidation resistance, and has good tensile properties from low temperature to 980 ℃. Fatigue performance, and stress corrosion resistance under salt spray.

Characteristic:

1. It has excellent corrosion resistance to various oxidation and reduction corrosion media

2. Resistance to spot corrosion and crevice corrosion, and no stress corrosion cracking caused by chloride

3. Corrosion resistance to inorganic acid, such as,, sulfuric acid, and mixed acid of sulfuric acid

4. Corrosion resistance of mixed inorganic acid solutions

5. When the temperature reaches 40 ℃, it has good corrosion resistance in various concentrations of solutions

6. Good processability and weldability, no post weld cracking

7. Manufacturing certification of pressure vessels with wall temperature of - 196~450 ℃

8.NACE certified by the American Society of Corrosion Engineers (MR-01-75) to meet the high grade VII for acid gas

Application:

- Components of organic chemical process containing chlorides, especially when using acidic chloride catalyst

- Boilers and bleachers for pulp and paper industry

- Absorber, reheater, flue gas inlet baffle, fan, agitator, deflector and flue in flue gas desulfurization

- Equipment and components used for manufacturing acid gas

- Acetic acid and reaction generator

- Sulfuric acid condenser.