INCONEL® alloy 625LCF (UNS N06626/W. Nr. 2.4856), developed as a fatigue-resistant type of INCONEL alloy 625. is crafted with controlled alloying, melting, and processing to offer a sheet product with impressive resistance to low-cycle and thermal fatigue up to 1200°F (650°C).

| Chemical Composition |

58Ni-12Cr-9Mo-3.5Nb-1Co-0.02C |

| Physical Property |

• Density: 8.44 g/cc

• Tensile Strength: 827 MPa

• Melting Range: 1290-1350 °C

• Yield Strength: 414 MPa |

| Stock & Dimensions |

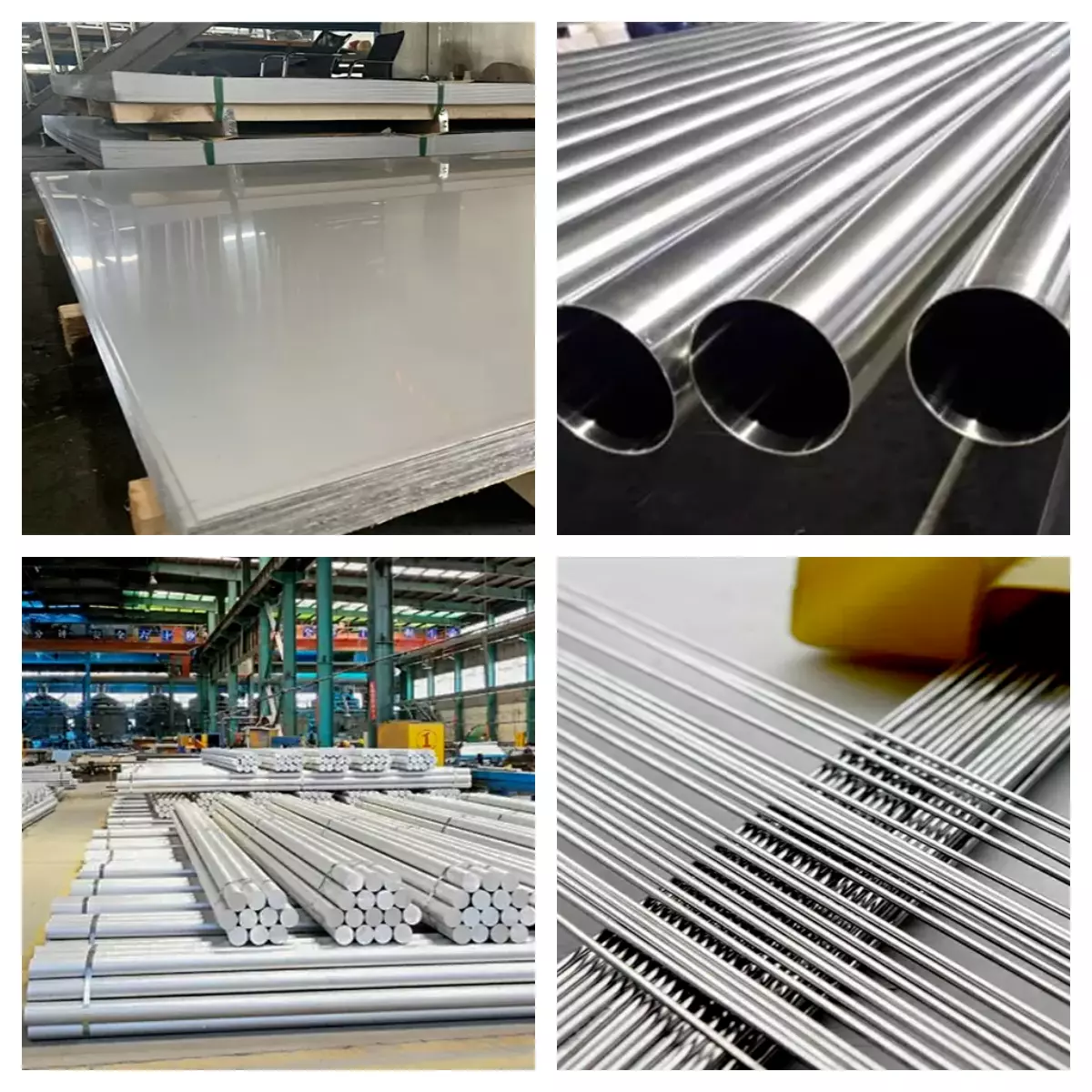

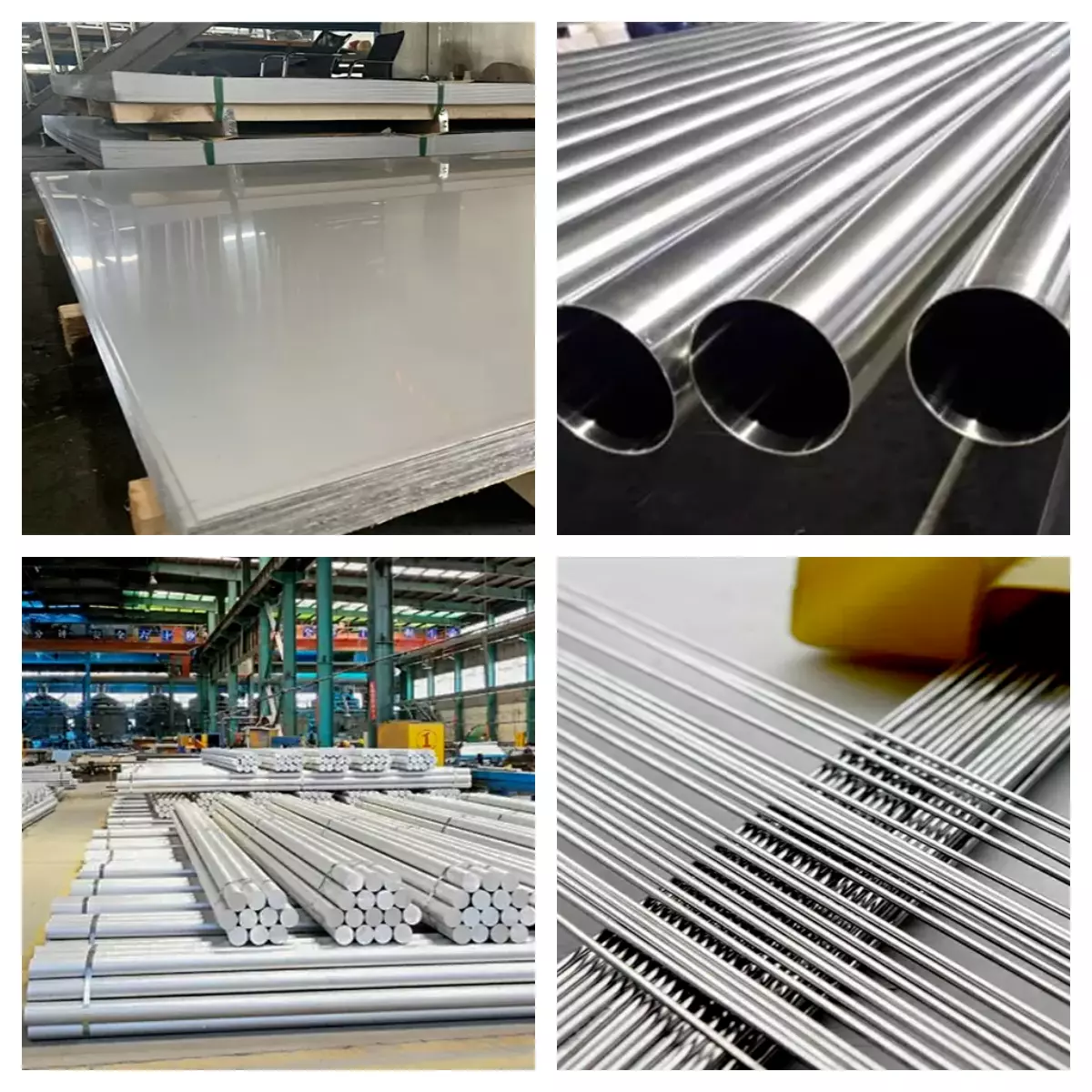

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

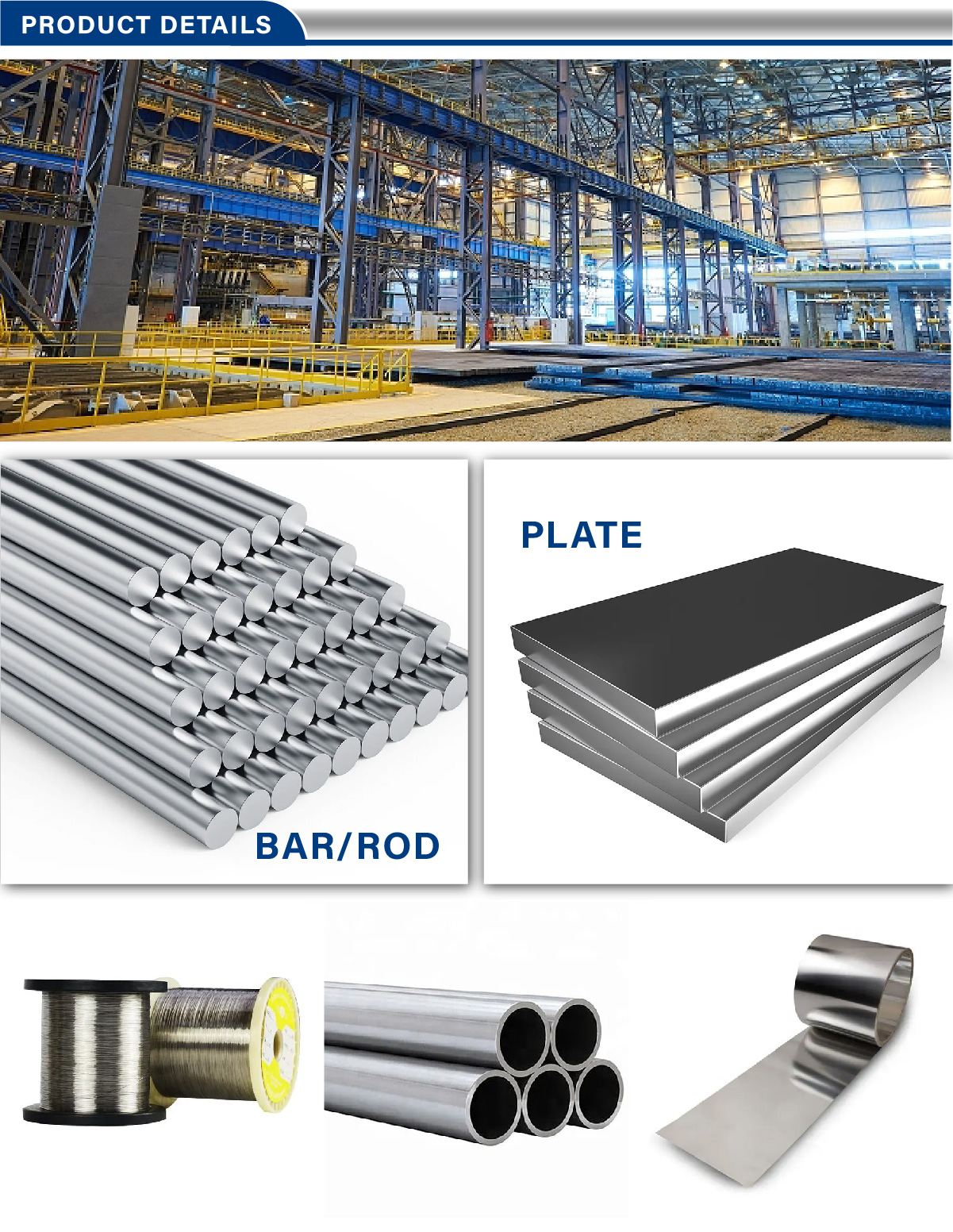

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

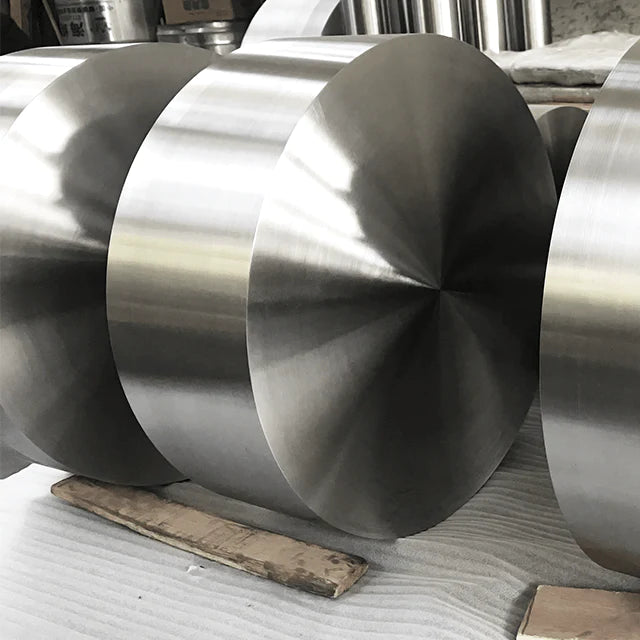

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Available Products:

INCONEL alloy 625LCF is available as cold-rolled, annealed sheet and strip in thicknesses from 0.005 - 0.100 in (0.13 - 2.54 mm). Widths up to 48 in (1220 mm) are available in flat, cut lengths or as coils up to 20.000 lb (9000 kg).

Application:

The alloy offers a high level of performance in aircraft exhaust and automotive flexible coupling bellows, expansion joints in process or transport piping, and other applications involving resistance to low-cycle or thermal fatigue.