Alloy 617 features a solid-solution composition of nickel, chromium, cobalt, and molydenum, providing exceptional strength and oxidation resistance at elevated temperatures. Additionally, this alloy is resistant to a broad range of corrosive settings and can be easily formed and welded with common techniques.

| Chemical Composition |

0.07C-22Cr-54Ni-9Mo-1AI-12.5Co |

| Physical Property |

• Density: 8.3g/cm³

• Tensile Strength: ≥ 485 MPa

• Yield Strength: ≥ 275 MPa

• Melting Point: 1363°C

• Hardness: 170 |

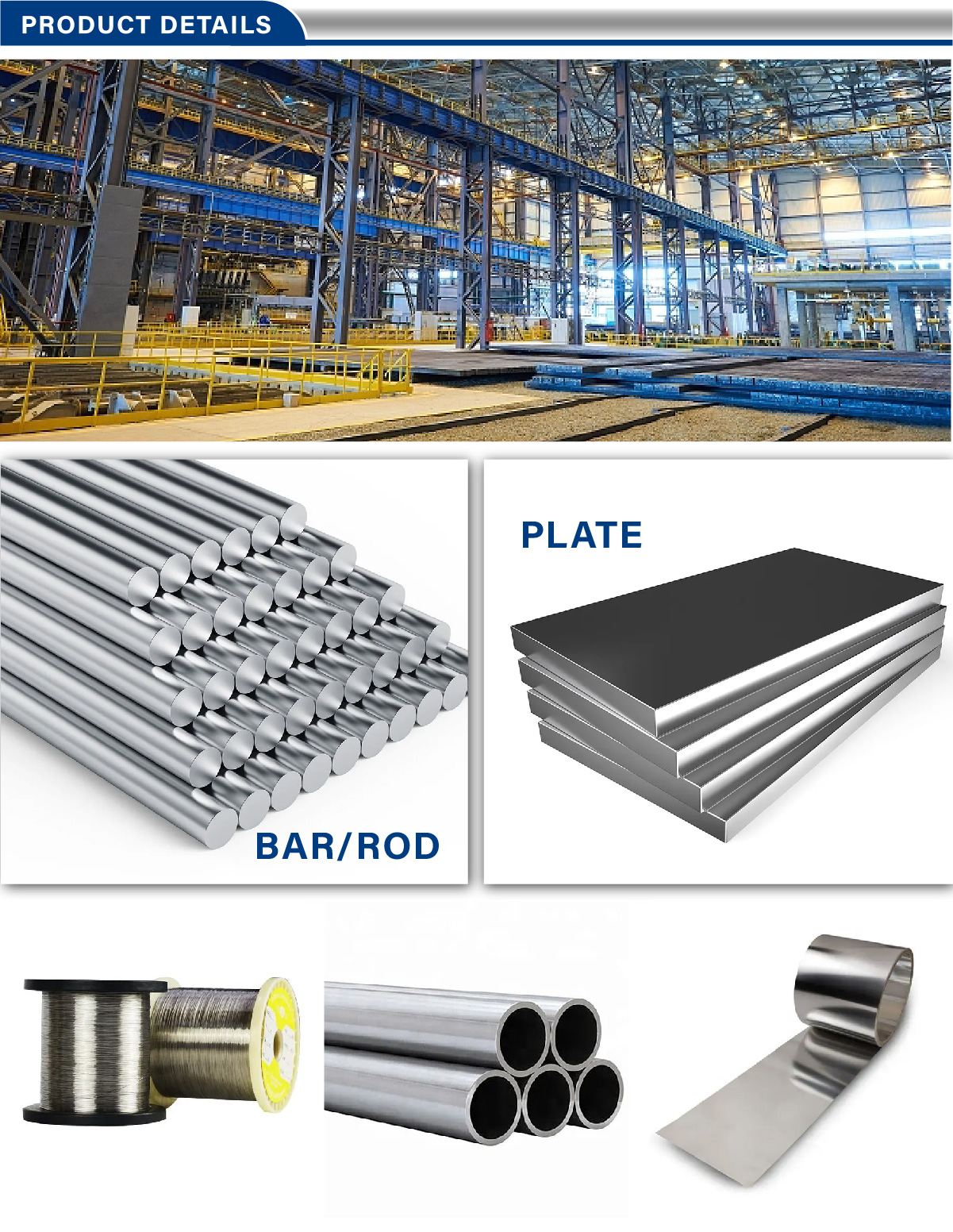

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

| Product Forms |

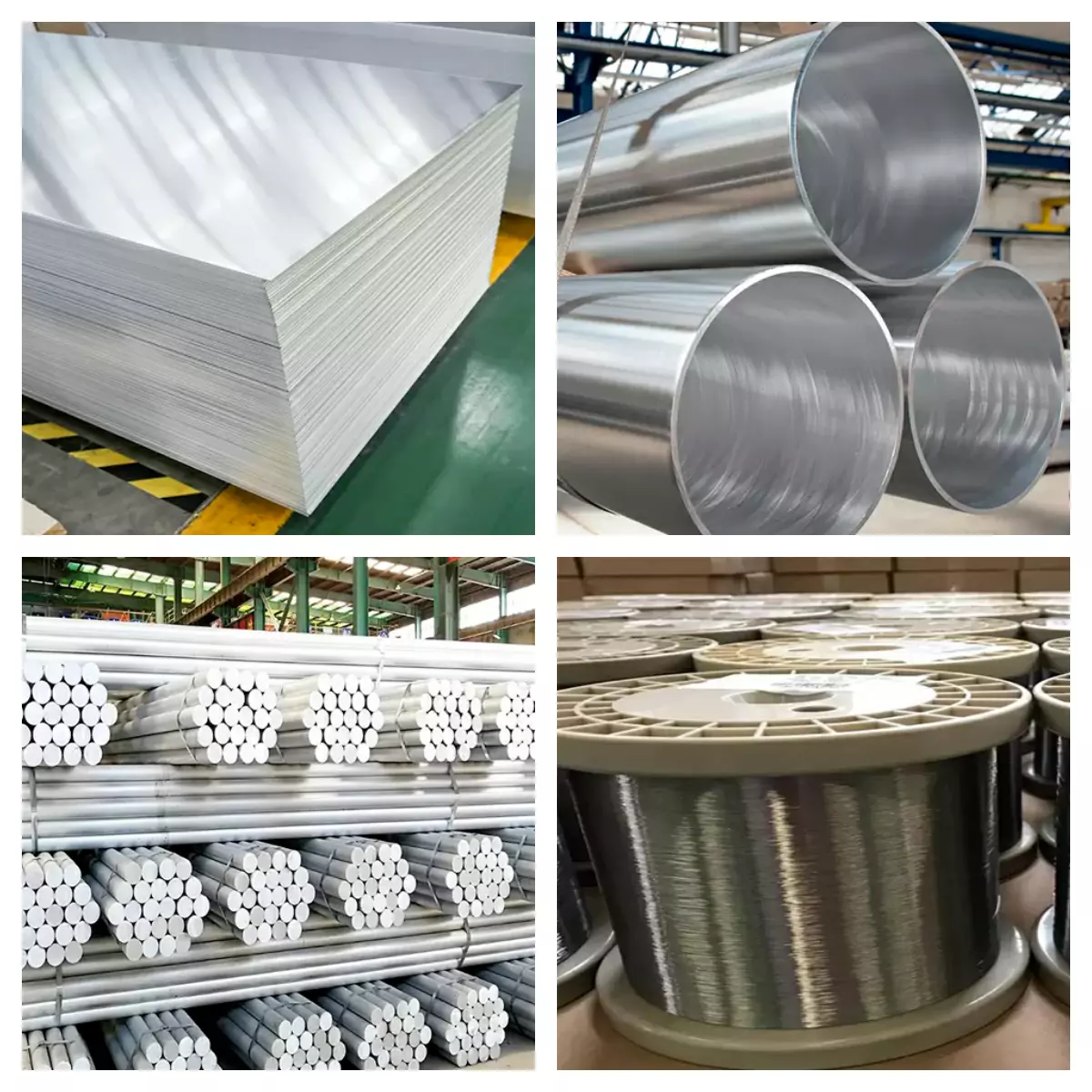

We provide you with a variety of product forms, including but not limited to:

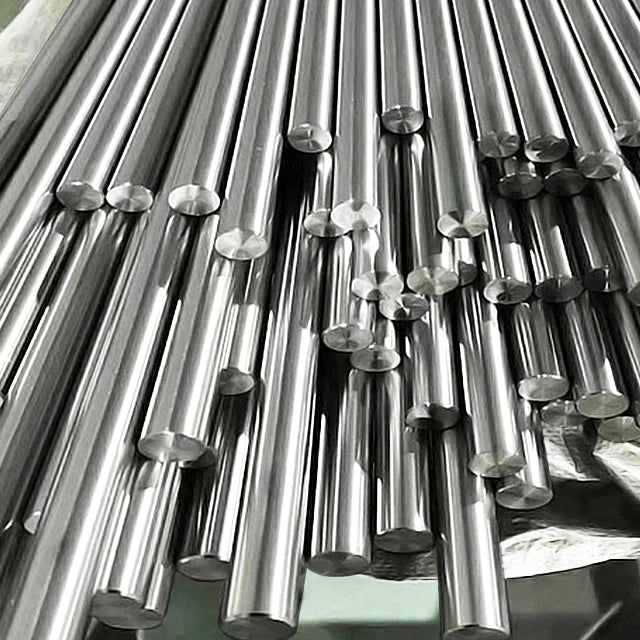

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Alloy 617 is a solid-solution, nickel-chromium-cobalt-molydenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environment, and it is readily formed and welded by conventional techniques.

The high nickel and chromium contents make the alloy resistant to a variety of both reducing and oxidizing media. The aluminum, in conjunction with the chromium, provides oxidation resistance at high temperatures. Solid-solution strengthening is imparted by the cobalt and molydenum.

Applications:

- Industrial furnace components

- Gas turbines

- Catalyst grid supports for nitric acid production

- Nuclear and fossil fuel productions