Inconel 601 is a nickel-chromium alloy equipped to survive in high temperature environments and has proven effective in combating stress corrosion cracking. It is employed in a variety of industrial processes, including heat treating, gas turbine components, and petrochemical operations.

| Chemical Composition |

60Ni-22Cr-1.2AI-0.5Cu-0.02C |

| Physical Property |

• Density: 8.05 g/cm³

• Tensile Strength: 790 MPa

• Yield Strength: 440 MPa

• Specific Heat: 0-100 ℃

• Elongation:45 |

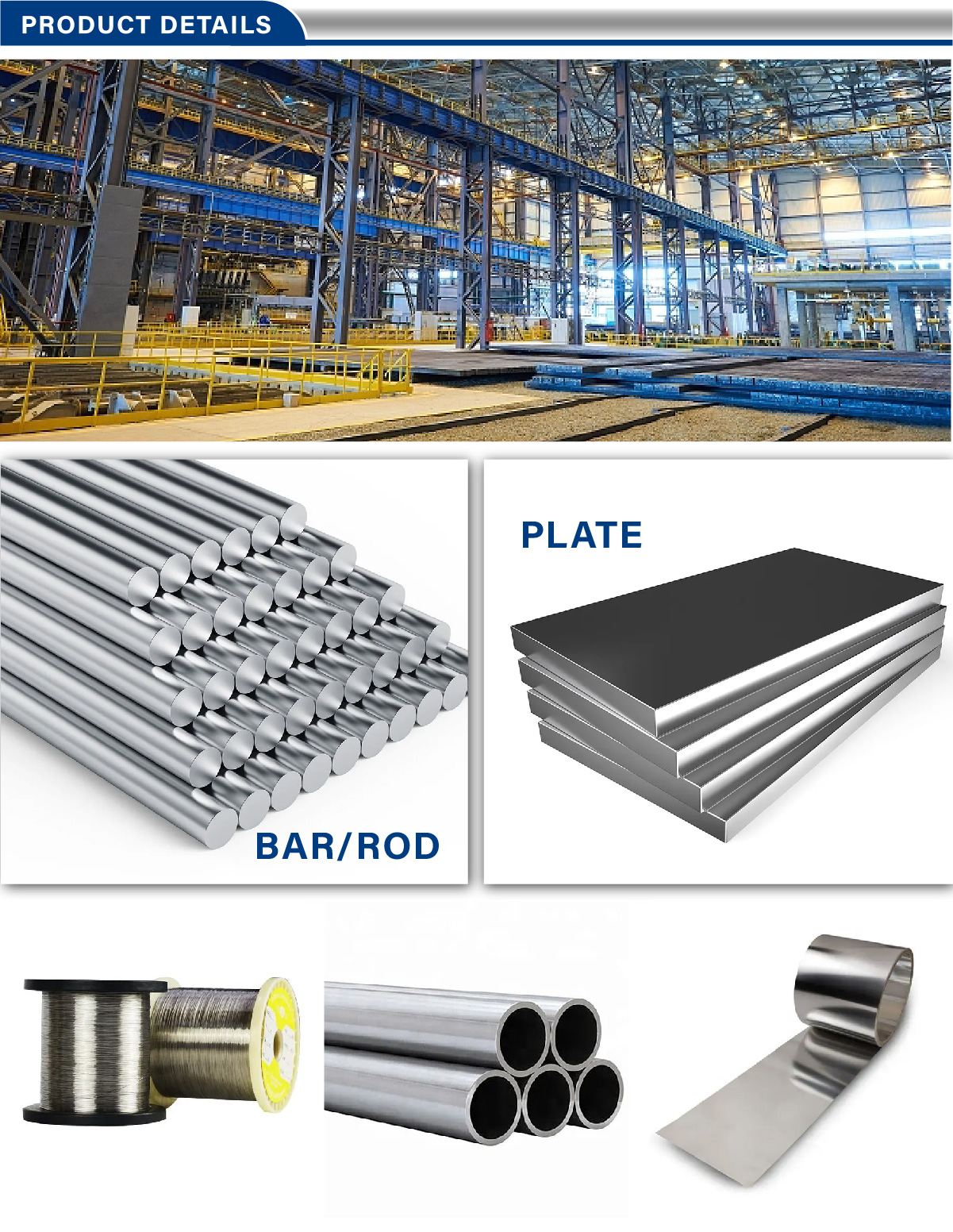

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

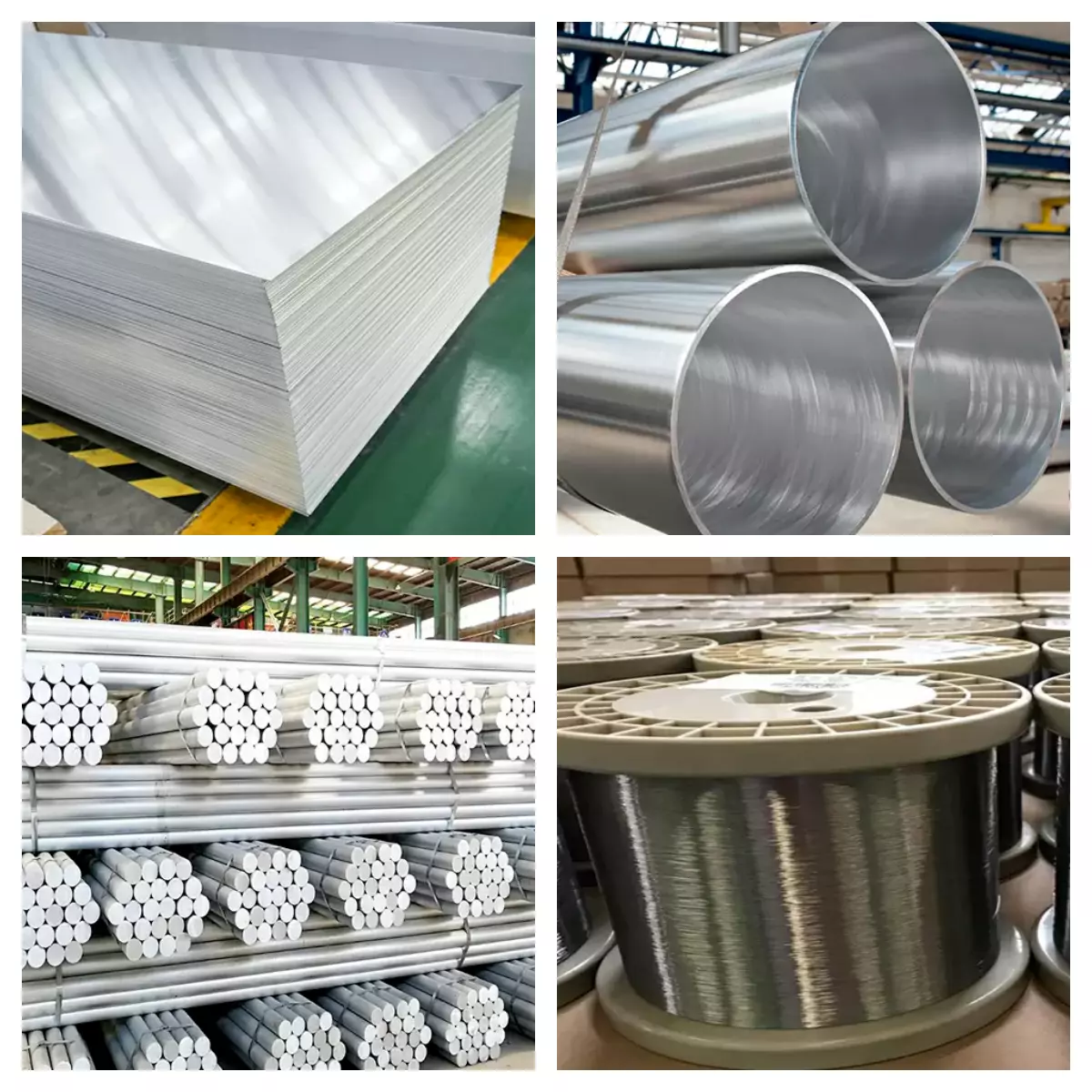

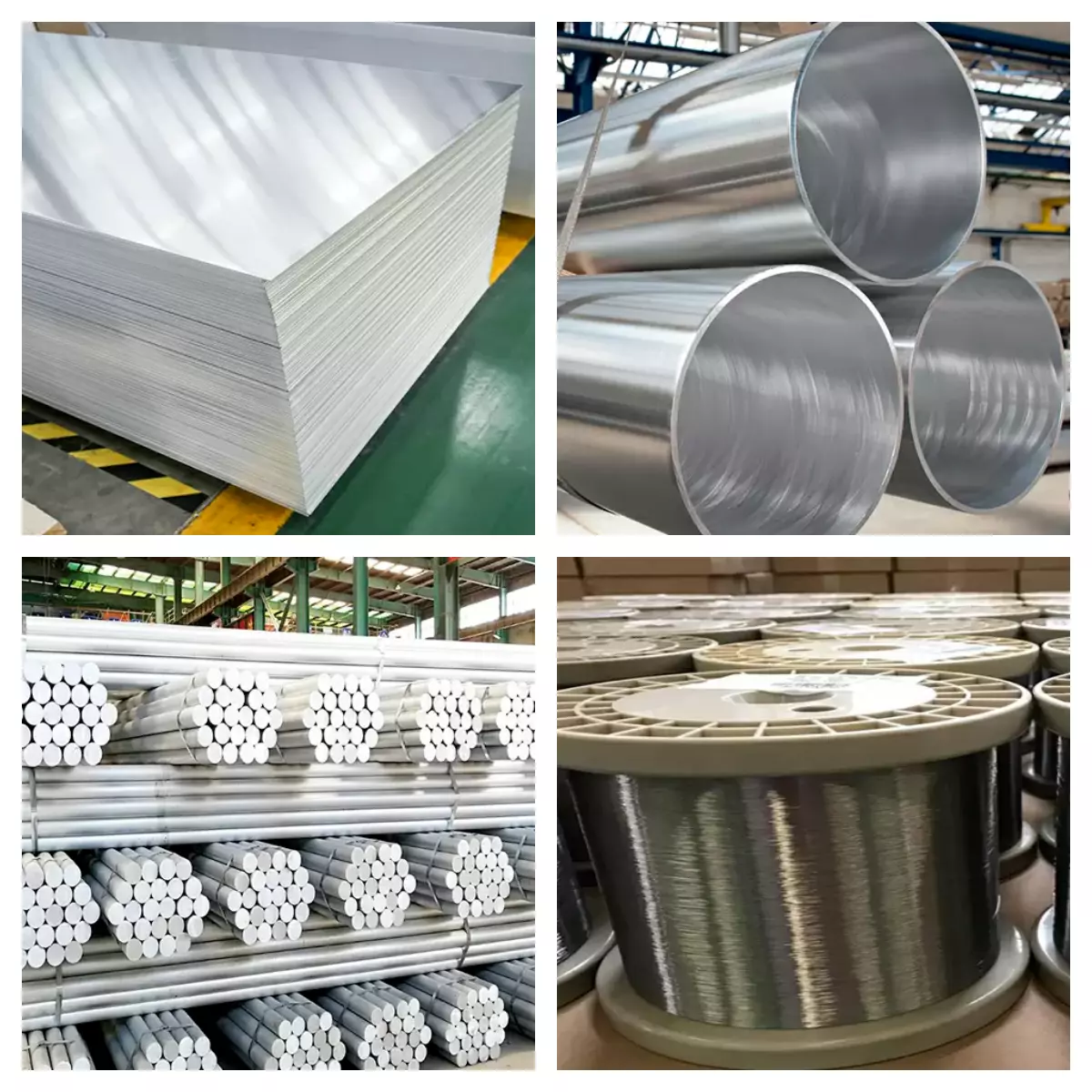

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Alloy 601 (UNS designation N06601) is a nickel-chromium alloy designed for use in high temperature applications. Compared to Alloy 600 (UNS designation N06600), Alloy 601 has increased chromium as well as the addition of aluminum which forms a tough oxide scale at elevated temperatures which gives the alloy excellent resistance to oxidation through 2200°F under cyclic conditions.

The alloy has good resistance to stress corrosion cracking. The alloy is not recommended for use in reducing or sulfur environments. The alloy is used extensively in heat treating applications, industrial furnaces, gas turbine components, and in petrochemical and pollution control equipment and systems.

Application:

- Heat treating baskets, trays and fixtures

- Radiant tubes, supports, return bends, muffles and retorts

- Combustor components and catalyst grid supports in equipment for nitric acid production

- Superheater tube supports and grid supports and ash handling systems in the power generation field

- Turbine engine igniters and combustion can liners, diffuser assemblies and containment rings