Hastelloy G-35 alloy boasts unparalleled resistance to oxidizing acids and nitric acid mixes, along with moderate resistance to reducing acids due to its molybdenum content. Moreover, its resistance to hot sodium hydroxide-induced "caustic de-alloying" outmatches the resistance of other nickel-chromium-molybdenum alloys.

| Chemical Composition |

59Ni-33Cr-8Mo-2Fe-0.6Si-0.3Cu-0.03C |

| Physical Property |

• Density: 8.22 g/cm³

• Tensile Strength: 745 MPa

• Yield Strength: 348 MPa

• Thermal Conductivity: 10W/m.k

• Specific Heat: 450J/kg.k

• Melting Range: 1332-1361 ℃

• Elongation: 25% |

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

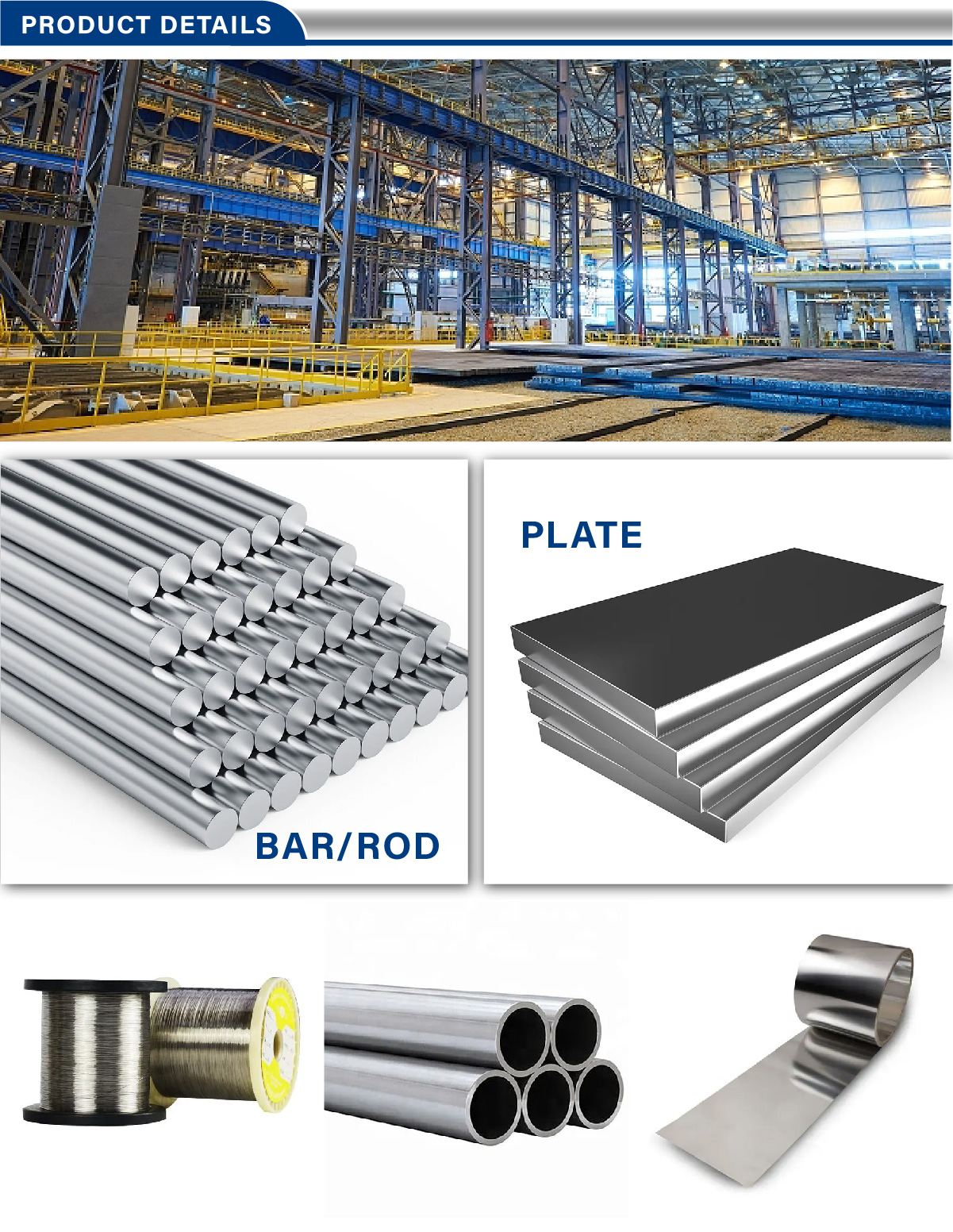

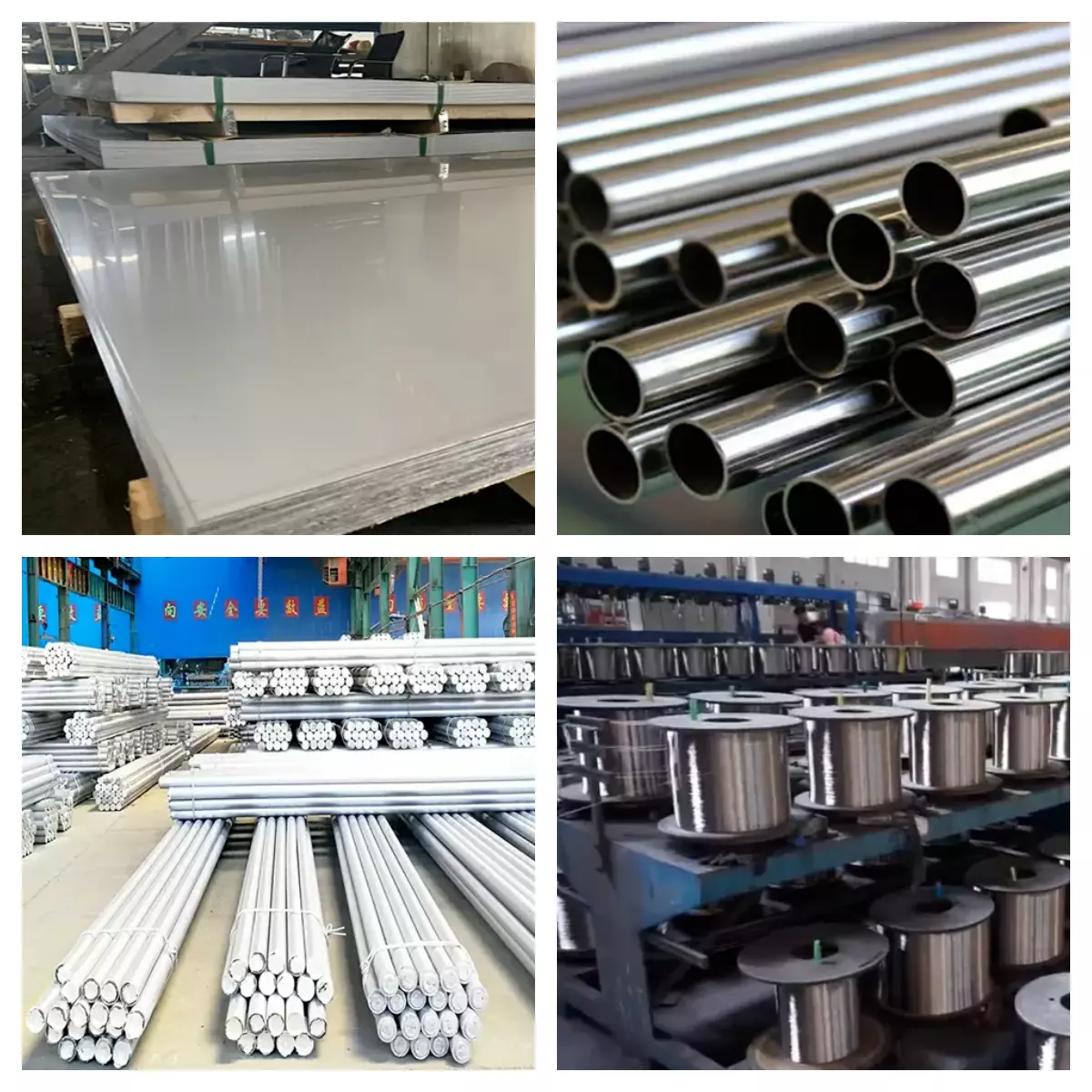

| Product Forms |

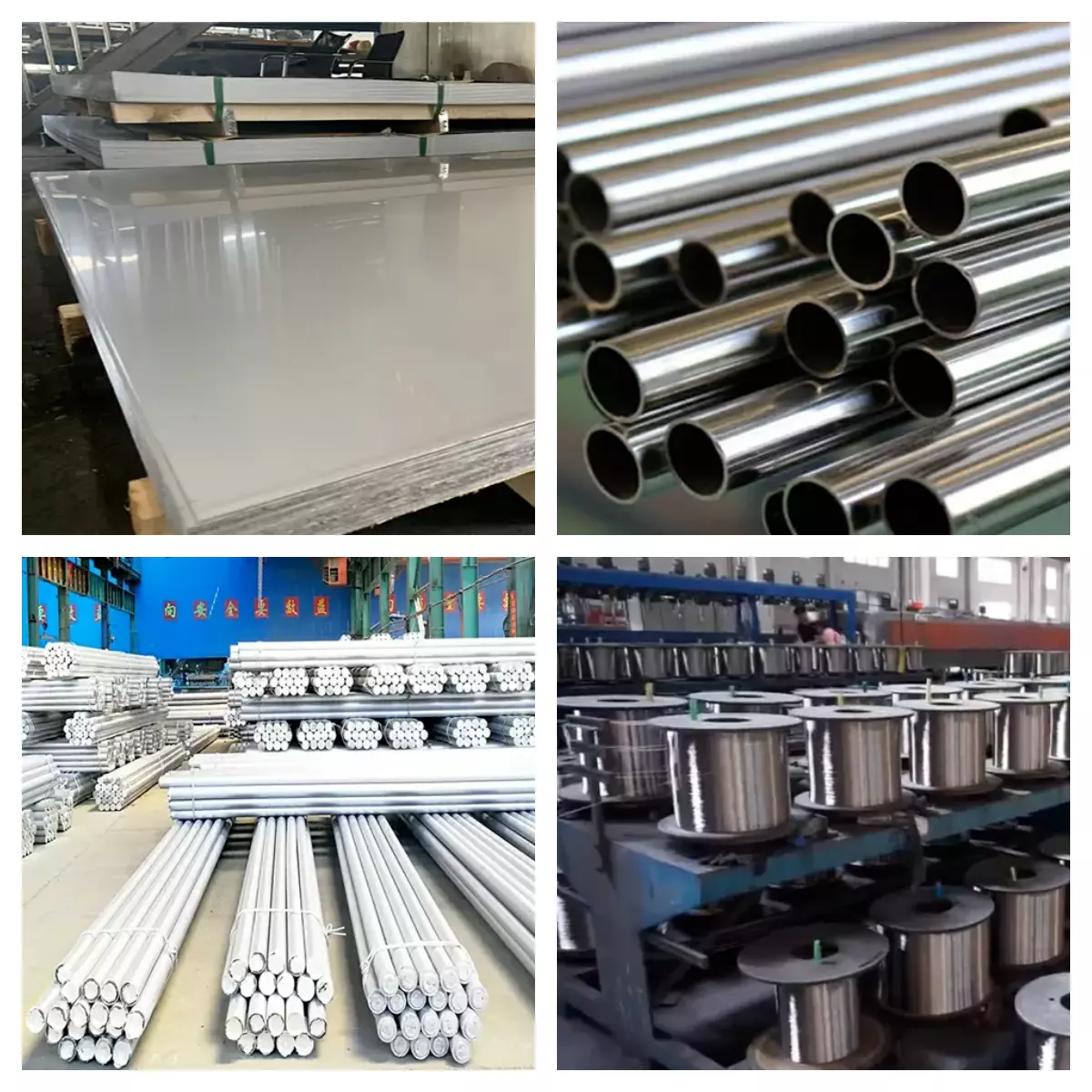

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Hastelloy G-30 is an improved version of nickel-chromium-iron-molybdenum-copper alloy G-3. With higher chromium, added cobalt and tungsten, the G-30 shows superior corrosion resistance over most other nickel and iron based alloys in commercial phosphoric acids as well as complex environments containing highly oxidizing acids. The resistance of the alloy to the formation of grain boundary precipitates in the heat-affected zone makes it suitable for use in most chemical process applications in the as-welded condition.

Applications:

- Marine engineering

- Furnace & gas turbines

- Chemical processing involving phosphoric acid, sulfuric acid and nitric acidNuclear fuel reprocessing, nuclear waste processing

- Pickling operations

- Petrochemical

- Fertilizer manufacture

- Pesticide manufacture

- Gold ore extraction