Hastelloy G-30 is favored for its excellent corrosion resistance to nitric acid, phosphoric acid, hydrochloric acid, and hydrofluoric acid. Even in welded form, its anti-corrosive characteristics remain intact. It also boasts high ductility.

| Chemical Composition |

43Ni-30Cr-15Fe-5.5Mo-2.5W-5Co-2Cu-1.5Mn-0.03C |

| Physical Property |

• Density: 8.22 g/cm³

• Tensile Strength: 1096 MPa

• Yield Strength: 1000 MPa

• Modulus of Elasticity: 202 GPa

• Elongation: 12% |

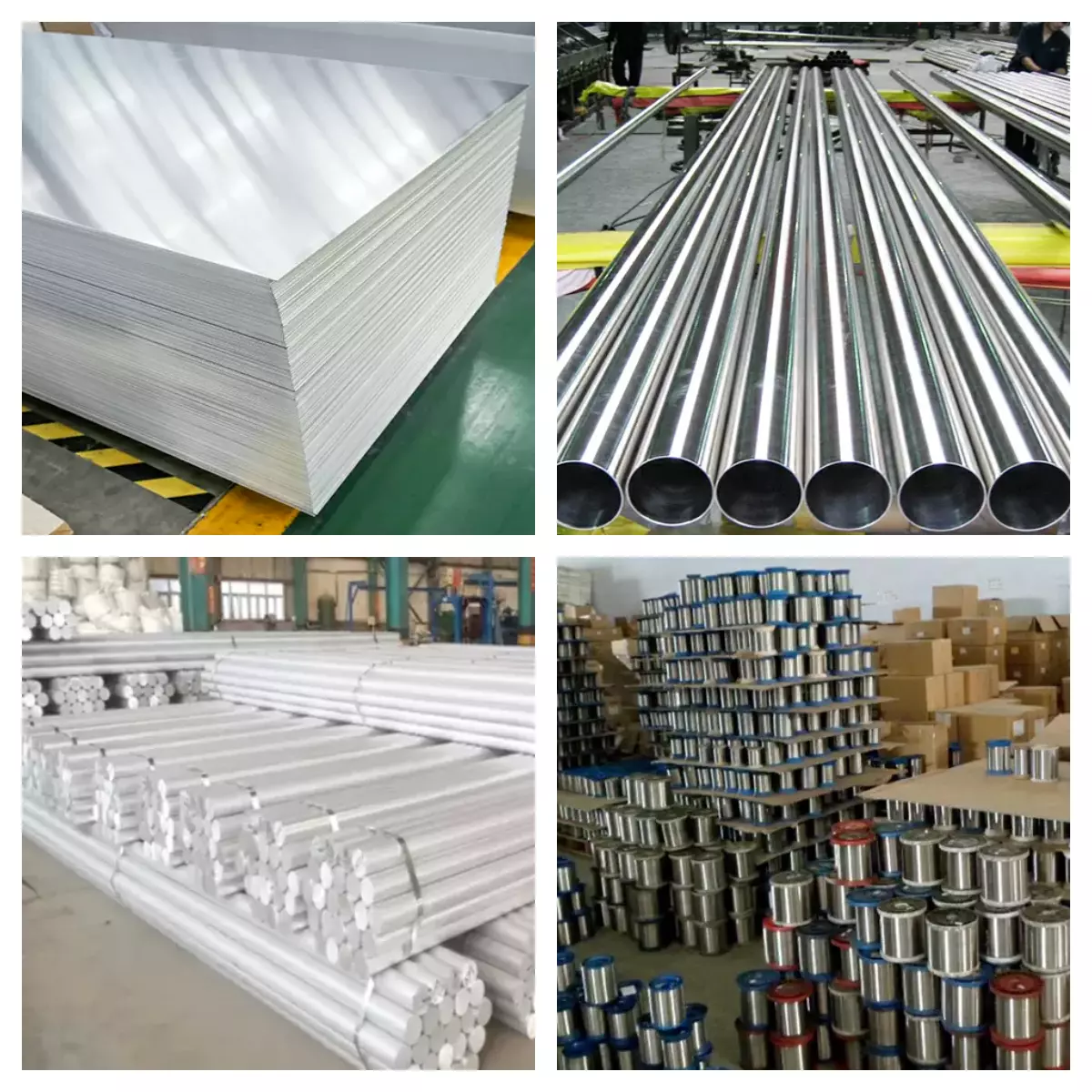

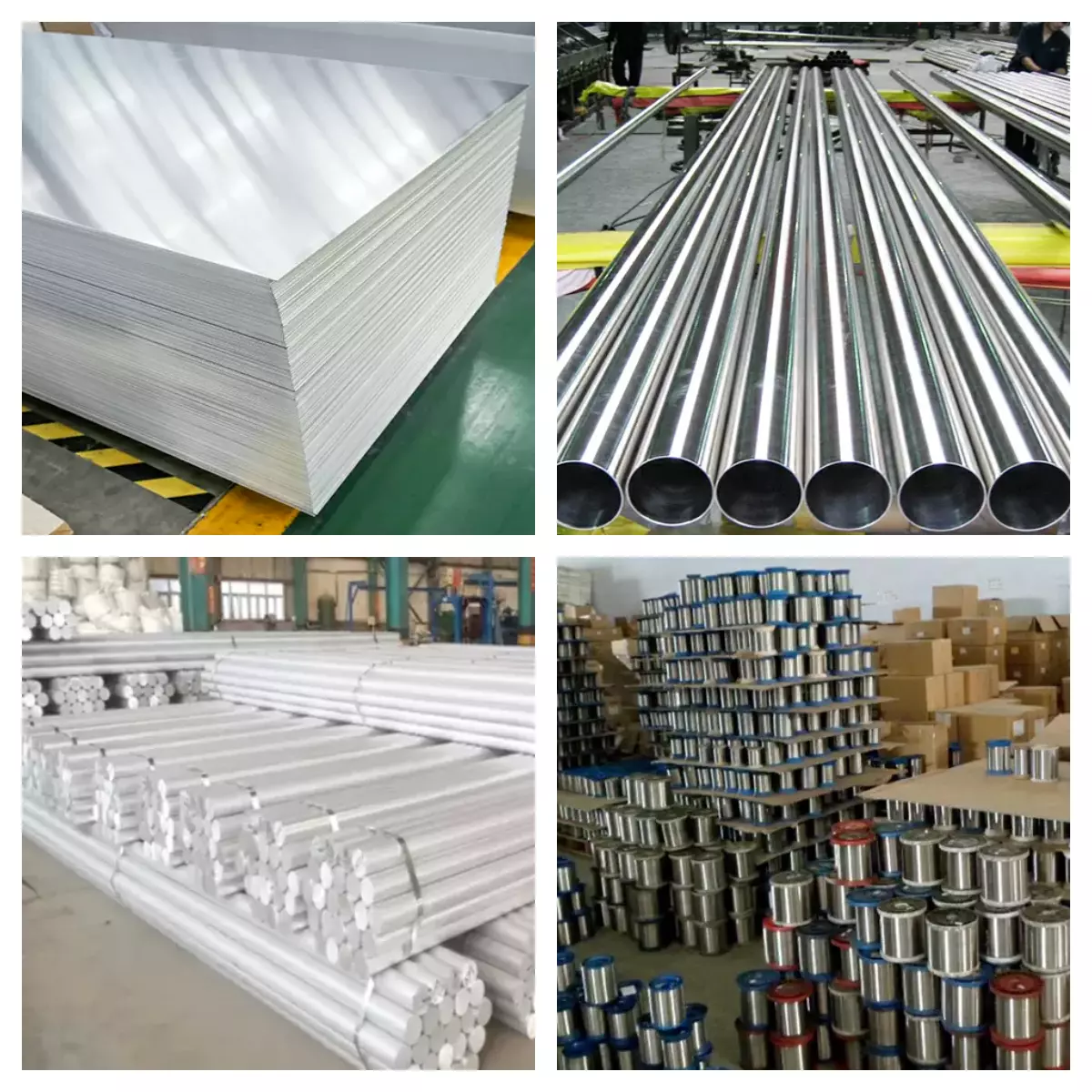

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

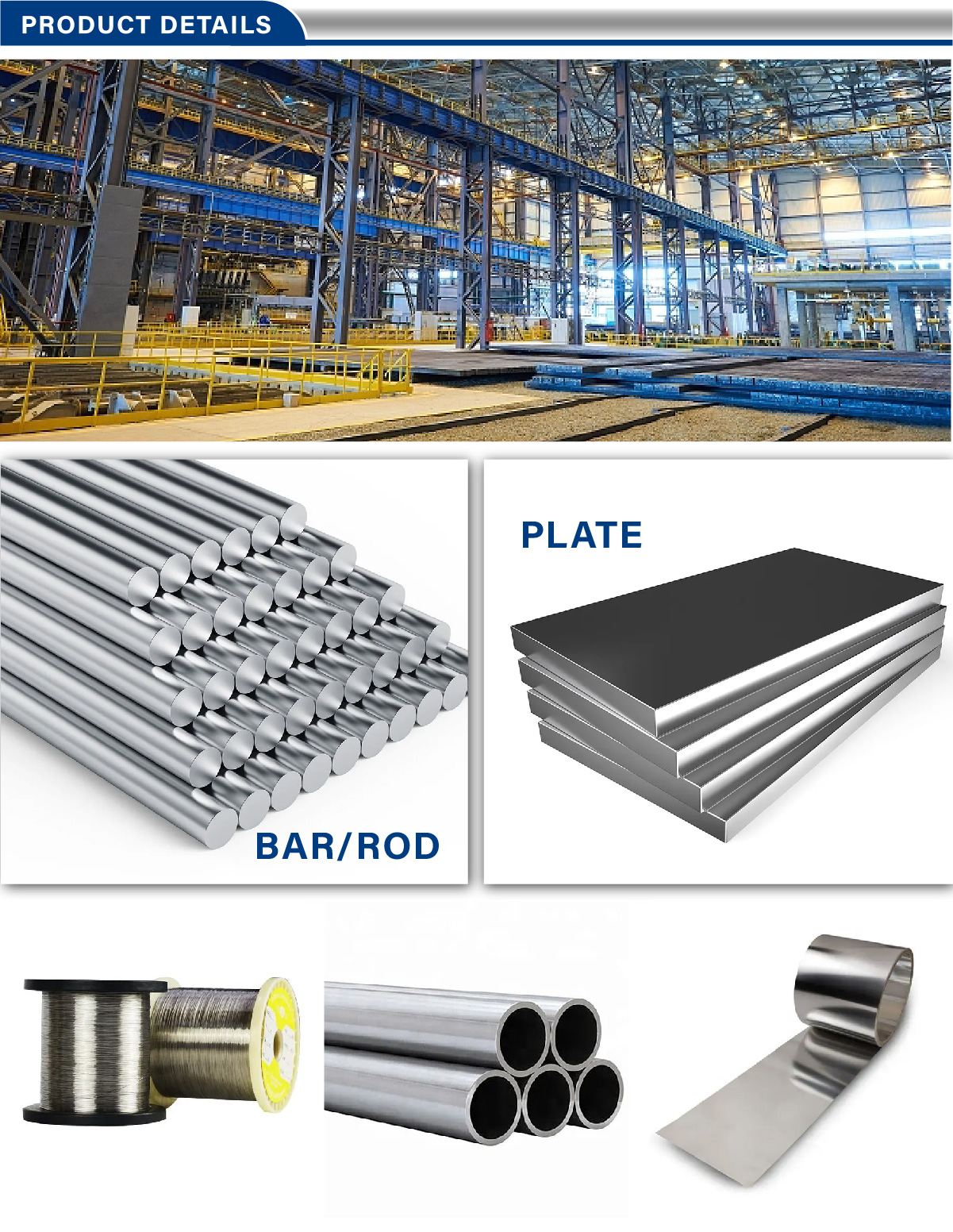

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

Hastelloy G-30 is commonly used for providing excellent resistance to chemical conditions. It offers resistance to nitric acid, phosphoric acid, hydrochloric acid and hydrofluoric acid. Corrosion resistance properties are also retained even in welded form. High ductility. It is used in chemical treatment plants, agitator blades, nuclear plants etc. The corrosion resistance offered by alloy G-30 to the production of grain precipitates in the heated area enables it for using in the chemical operations in the welded conditions.

Application:

- Phosphoric acid equipment

- Sulphuric acid equipment

- Nitric acid equipment

- Nuclear fuel reprocessing

- Nuclear waste disposal

- Pickling operations

- Petrochemical products

- Fertilizer production

- Pesticide production

- Gold extraction