Hastelloy C-22 boasts superior protection against pitting, crevice corrosion, and stress corrosion cracking. Additionally, this nickel-chromium-molybdenum alloy offers impressive resistance to both oxidizing and reducing media. C-22's robust weldability and corrosion resistance has been well-established as a quality filler wire and electrode.

| Chemical Composition |

56Ni-22Cr-13Mo-3Fe-3W-2.5Co-0.5Mn-0.36V-0.08Si-0.01C |

| Physical Property |

• Density: 8.69 g/cm³

• Tensile strength: 690 MPa

• Yield strength: 310 MPa

• Melting Range: 1357-1399 ℃

• Elongation: 45% min |

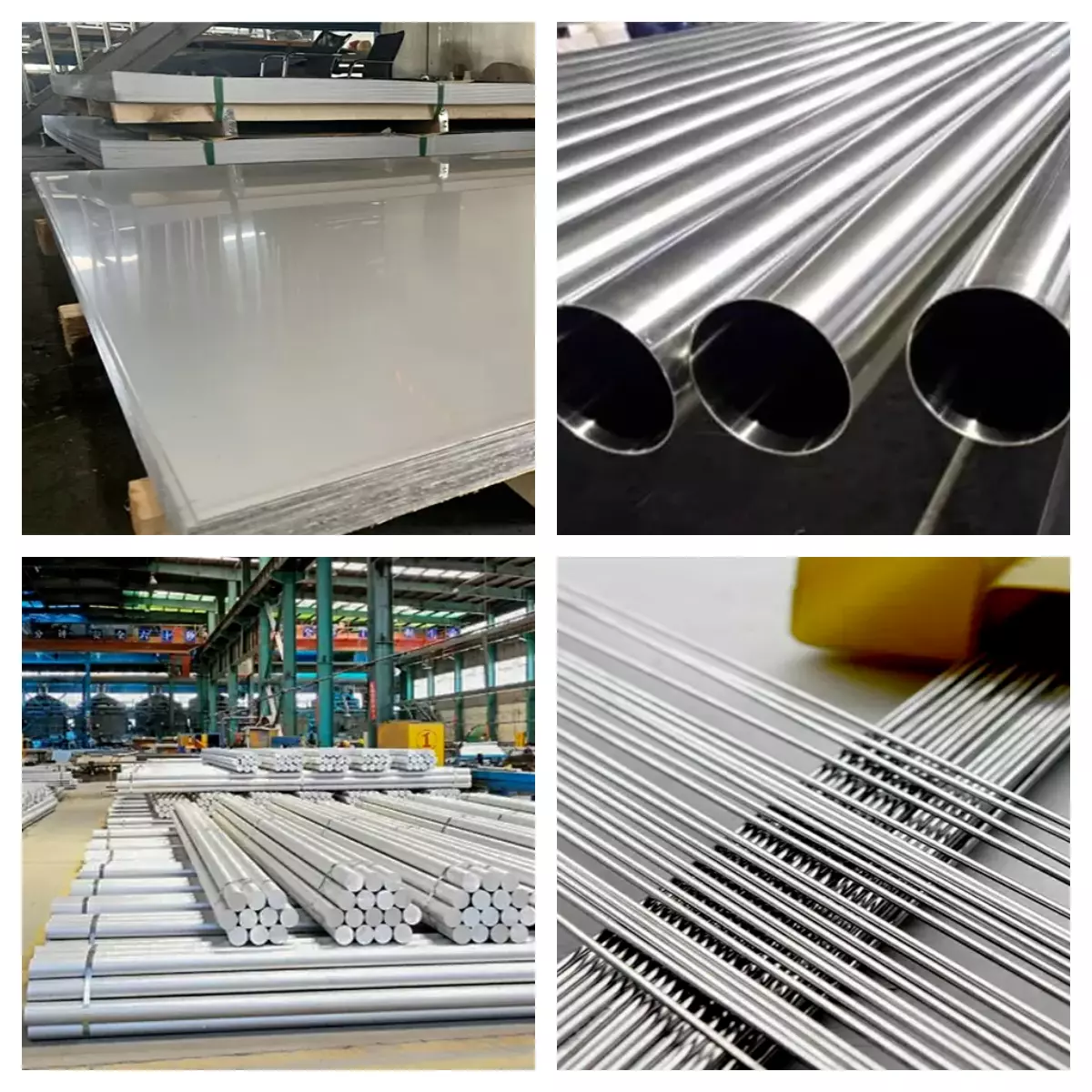

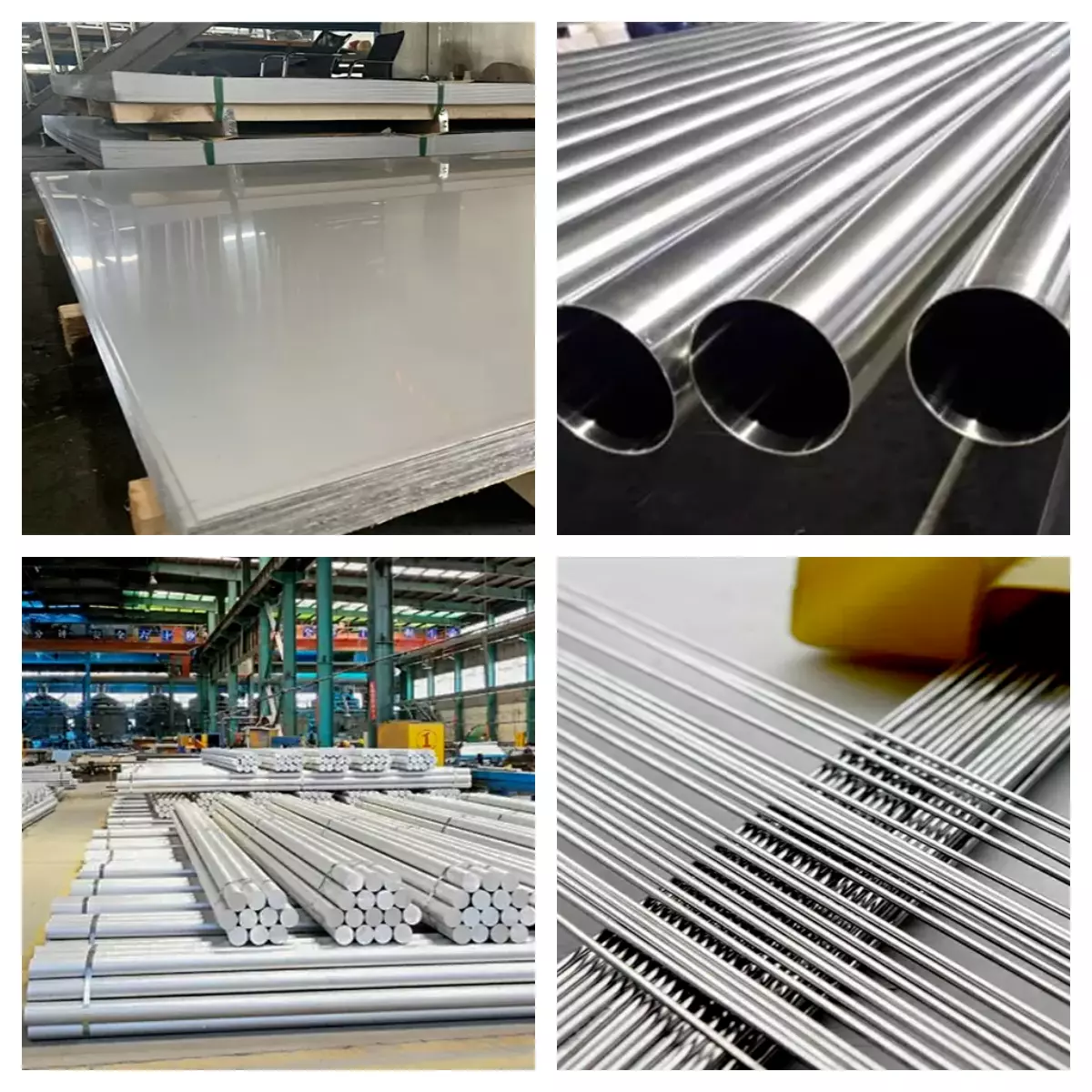

| Stock & Dimensions |

Our warehouse has a large number of stock to provide you with a variety of products in different sizes, and can also customize the size according to your needs.

• Bar: 0.5~600mm Diameter

• Coil: 0.5~150mm Thick

• Plate: 0.5~200mm Thick

• Pipe: 6~630mm External Diameter; 0.5~40mm Wall Tick

• Available in specific sizes |

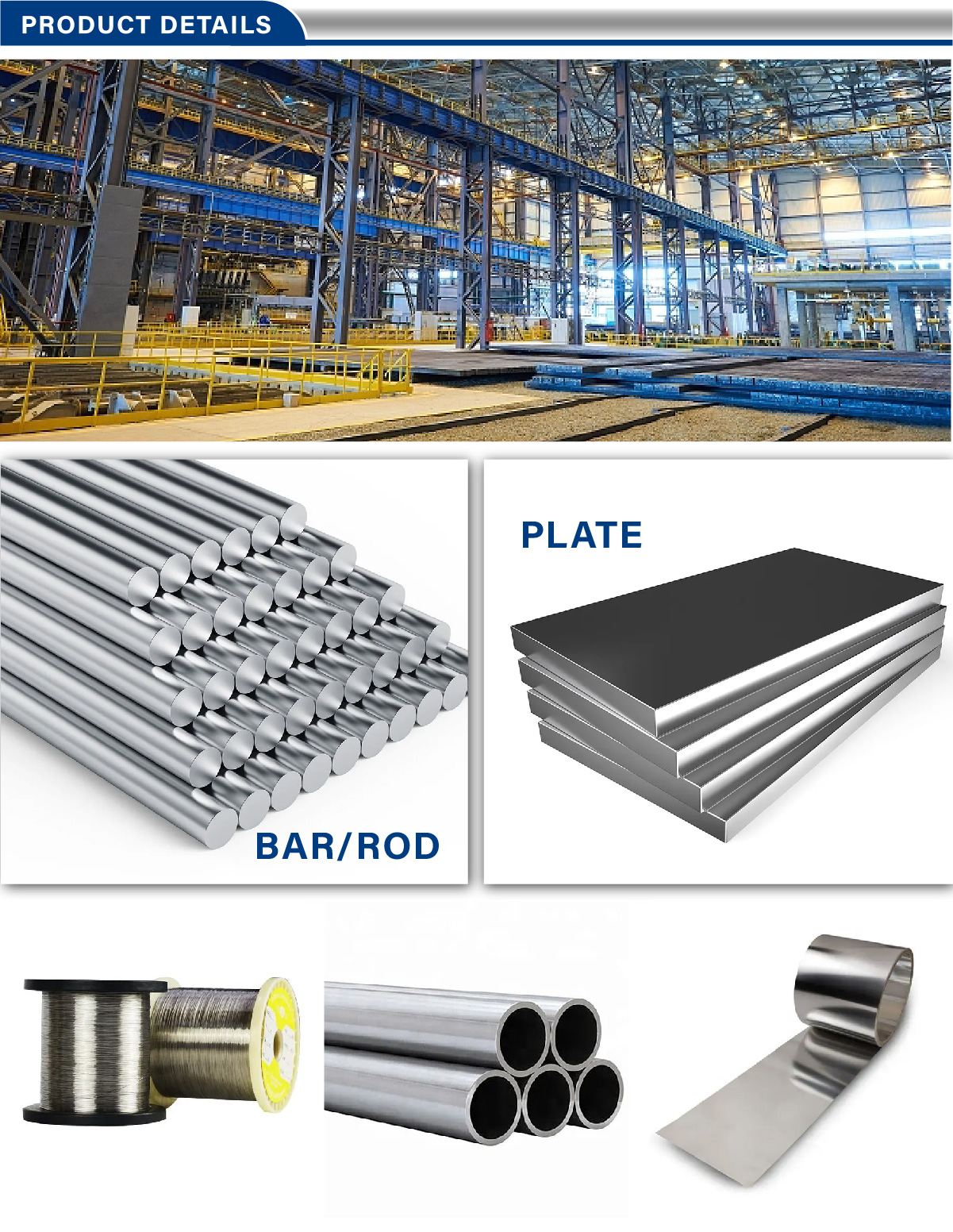

| Product Forms |

We provide you with a variety of product forms, including but not limited to:

• Bar/Rod

• Pipe/Tube

• Coil/Strip

• Plate/Sheet/Circle

• Wire

• Fitting (Flange, Elbow, Tee...)

• Customize |

Essential details

HASTELLOY Alloy C-22 is a nickel-chromium-molybdenum alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking. It resists the formation of grain boundary precipitates in the weld-heat affected zone making it suitable for use in the as-welded condition.

C-22 has outstanding resistance to both reducing and oxidizing media and because of its resistibility can be used where "upset" conditions are likely to occur. It is proven to possess excellent weldability and high corrosion resistance as consumable filler wires and electrodes. The alloy has proven results as a filler wire in many applications. As filler wire use when other corrosion resistant wires have failed.

C-22 can easily be cold-worked because of its ductility and cold-forming is the preferred method of forming. More energy is required because the alloy is generally stiffer than austenitic stainless steels.

Applications:

- Chlorination systems

- Flue gas scrubbers

- Outlet ducting and stack liners for power plants, pulp and paper bleach plants, sulfur dioxide scrubbers, and weld overlay of less corrosion resistant metals

- Acid production and pickling systems